3-Stage Telescopic Hydraulic Cylinders for Dump Trucks

When it comes to dump truck performance, few components are as critical as the hydraulic cylinder system. Among various options, 3-stage telescopic hydraulic cylinders have become the industry standard for heavy-duty dumping operations. These multi-stage workhorses provide the extended reach and powerful lifting capacity needed to handle demanding loads efficiently. Unlike single-stage cylinders, the telescopic design allows for compact storage while delivering impressive vertical extension when activated. For truck owners and fleet managers, understanding the engineering behind these systems can mean the difference between optimal performance and costly downtime.

How 3-Stage Telescopic Hydraulic Cylinders Work

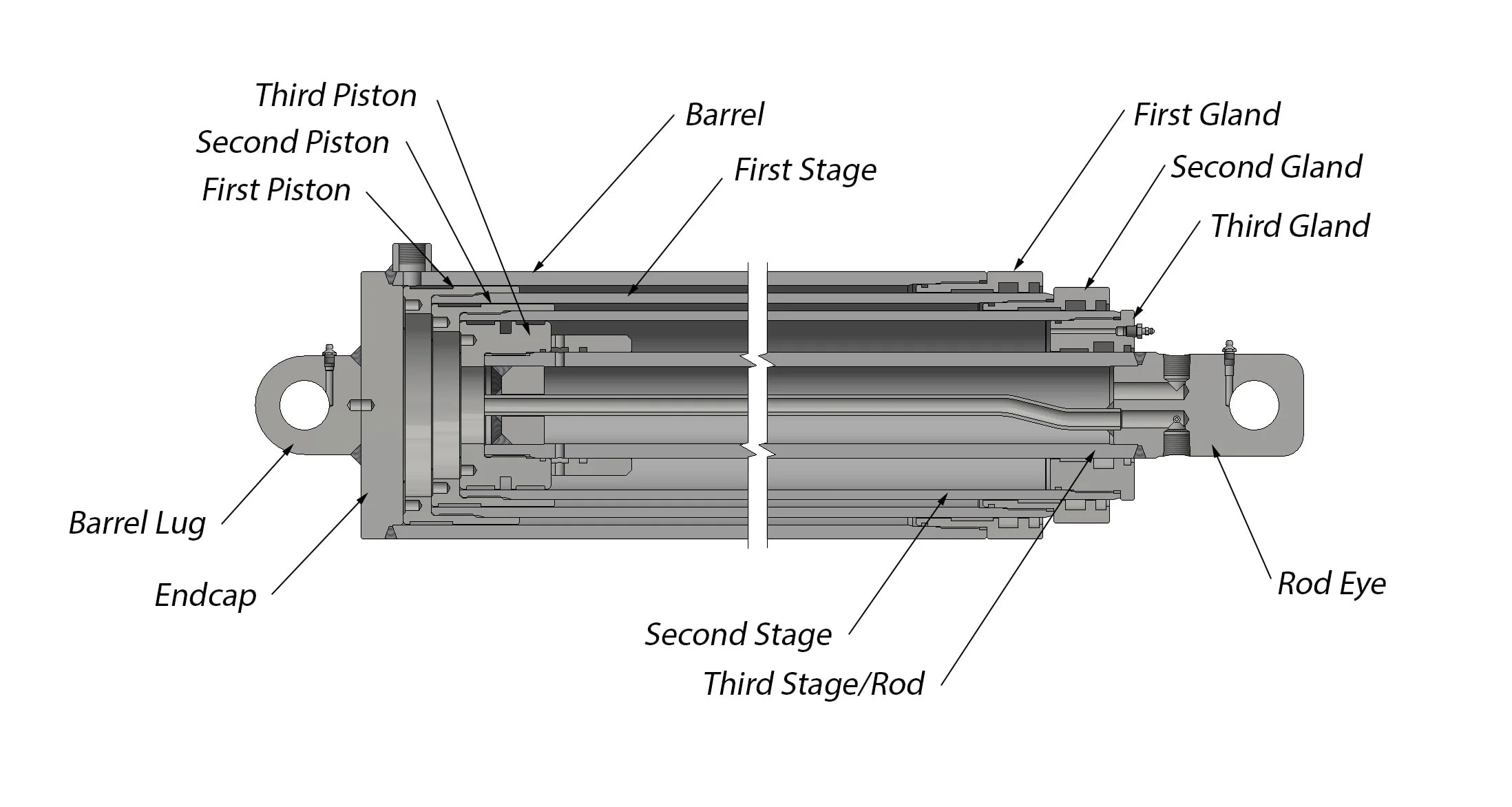

The fundamental operation of 3-stage telescopic hydraulic cylinders involves a nested series of tubular sections that extend sequentially. When hydraulic pressure is applied, the largest diameter section (known as the barrel) extends first, followed by progressively smaller stages. This sequential deployment creates a much longer extension than would be possible with a single-stage cylinder of the same collapsed length.

The hydraulic fluid enters through the base port, creating pressure against the piston. This pressure forces each stage to extend in order, with mechanical stops or hydraulic sequencing controlling the extension pattern. The retraction process works in reverse, with the smallest stage retracting first, followed by the intermediate and main stages.

Key advantages of this design include:

- Compact storage dimensions when retracted

- Significant vertical reach when fully extended

- High lifting capacity distributed across multiple stages

- Smooth, controlled extension and retraction cycles

Engineering Specifications and Performance Metrics

Understanding the technical specifications of 3-stage telescopic hydraulic cylinders helps in selecting the right system for your dump truck application. The performance characteristics vary significantly between models and manufacturers.

| Parameter | Standard Duty | Heavy Duty | Extra Heavy Duty |

|---|---|---|---|

| Working Pressure (PSI) | 2,500-3,000 | 3,000-3,500 | 3,500-4,000+ |

| Bore Diameter Range | 4-6 inches | 6-8 inches | 8-10+ inches |

| Stroke Length | 60-100 inches | 100-140 inches | 140-180 inches |

| Typical Lift Capacity | 10-20 tons | 20-40 tons | 40-60+ tons |

According to data from the Society of Automotive Engineers, properly maintained hydraulic systems can maintain 95% of their original efficiency after 10,000 operating cycles. This durability makes them particularly valuable for commercial applications where reliability directly impacts profitability.

Critical Design Features for Optimal Performance

Several engineering elements separate high-quality 3-stage telescopic hydraulic cylinders from inferior alternatives. The materials used in construction typically include high-tensile strength steel for the barrel and stages, with chrome-plated piston rods for enhanced wear resistance and corrosion protection.

Sealing systems represent another critical component. Advanced polyurethane seals with reinforced backup rings provide superior leak prevention compared to traditional rubber seals. The sealing configuration must handle both static and dynamic pressure conditions while resisting contamination from external debris.

Mounting configurations vary depending on the dump truck body design and intended application. Common mounting styles include:

- Trunnion mount with pivot points for articulated movement

- Flange mount for direct connection to the frame

- Clevis mount with pin connections for rotational freedom

- Side-pin mount for specific body designs

Maintenance Best Practices and Troubleshooting

Regular maintenance significantly extends the service life of 3-stage telescopic hydraulic cylinders. The most critical maintenance task involves monitoring hydraulic fluid quality and contamination levels. Industry studies show that approximately 70% of hydraulic system failures result from fluid contamination, according to research published by the American Society for Testing and Materials.

Weekly inspections should include visual checks for external damage, fluid leaks, and misalignment. Monthly maintenance should address:

- Checking all connection points for proper torque

- Inspecting rod surfaces for scratches or pitting

- Verifying proper fluid levels and condition

- Testing cylinder operation through full extension/retraction cycles

Common issues with 3-stage telescopic hydraulic cylinders include uneven extension, slow operation, and failure to maintain position. These problems often stem from worn seals, contaminated fluid, or internal damage to the barrel or piston surfaces. Addressing these issues promptly prevents more extensive damage to the system.

Selection Criteria for Different Applications

Choosing the right 3-stage telescopic hydraulic cylinder requires careful consideration of several factors beyond basic size and capacity ratings. The operating environment plays a crucial role in material selection, with corrosive environments necessitating stainless steel components or specialized coatings.

Load characteristics significantly influence cylinder selection. For example, dump trucks handling abrasive materials like sand or gravel require different seal configurations than those handling demolition debris. The cycling frequency also impacts design choices, with high-cycle applications benefiting from enhanced sealing systems and premium materials.

Industry expert Michael Torres, a certified fluid power specialist with over 20 years of experience in heavy equipment hydraulics, emphasizes that “matching the cylinder specifications to both the immediate requirements and anticipated future needs prevents premature failure and reduces total ownership costs. Don’t just consider today’s applications – think about what you might be hauling in three to five years.”

Frequently Asked Questions

How long should a 3-stage telescopic hydraulic cylinder last?

With proper maintenance and normal operating conditions, high-quality 3-stage telescopic hydraulic cylinders typically last between 5,000 and 10,000 operating hours. Severe service conditions or inadequate maintenance can reduce this lifespan significantly.

What are the signs that my hydraulic cylinder needs rebuilding?

Visible fluid leaks, slow or uneven extension, inability to maintain position under load, and visible scoring on the piston rod indicate that rebuilding or replacement is necessary. Unusual noises during operation also suggest internal damage.

Can I repair a damaged telescopic hydraulic cylinder myself?

While basic maintenance tasks are owner-serviceable, major repairs should be handled by qualified technicians. Specialized tools, press equipment, and technical knowledge are required for proper disassembly, seal replacement, and reassembly of 3-stage telescopic hydraulic cylinders.

How do I determine the right size cylinder for my dump truck?

Consult your truck manufacturer’s specifications and consider your typical load weight, desired dump angle, and available mounting space. Working with a qualified hydraulic specialist ensures proper sizing for your specific application.

What’s the difference between single-acting and double-acting telescopic cylinders?

Single-acting cylinders use hydraulic pressure to extend but rely on gravity for retraction. Double-acting cylinders use hydraulic pressure for both extension and retraction, providing better control in all operating conditions.

Conclusion

3-stage telescopic hydraulic cylinders represent a sophisticated engineering solution that balances compact storage requirements with extended reach capabilities. Their design and construction directly impact dump truck performance, reliability, and operating costs. By understanding their operation, maintenance requirements, and selection criteria, truck owners and operators can maximize equipment uptime and productivity. Regular maintenance coupled with proper operation ensures these critical components deliver their full potential throughout their service life.

Sources:

Society of Automotive Engineers

American Society for Testing and Materials

National Fluid Power Association