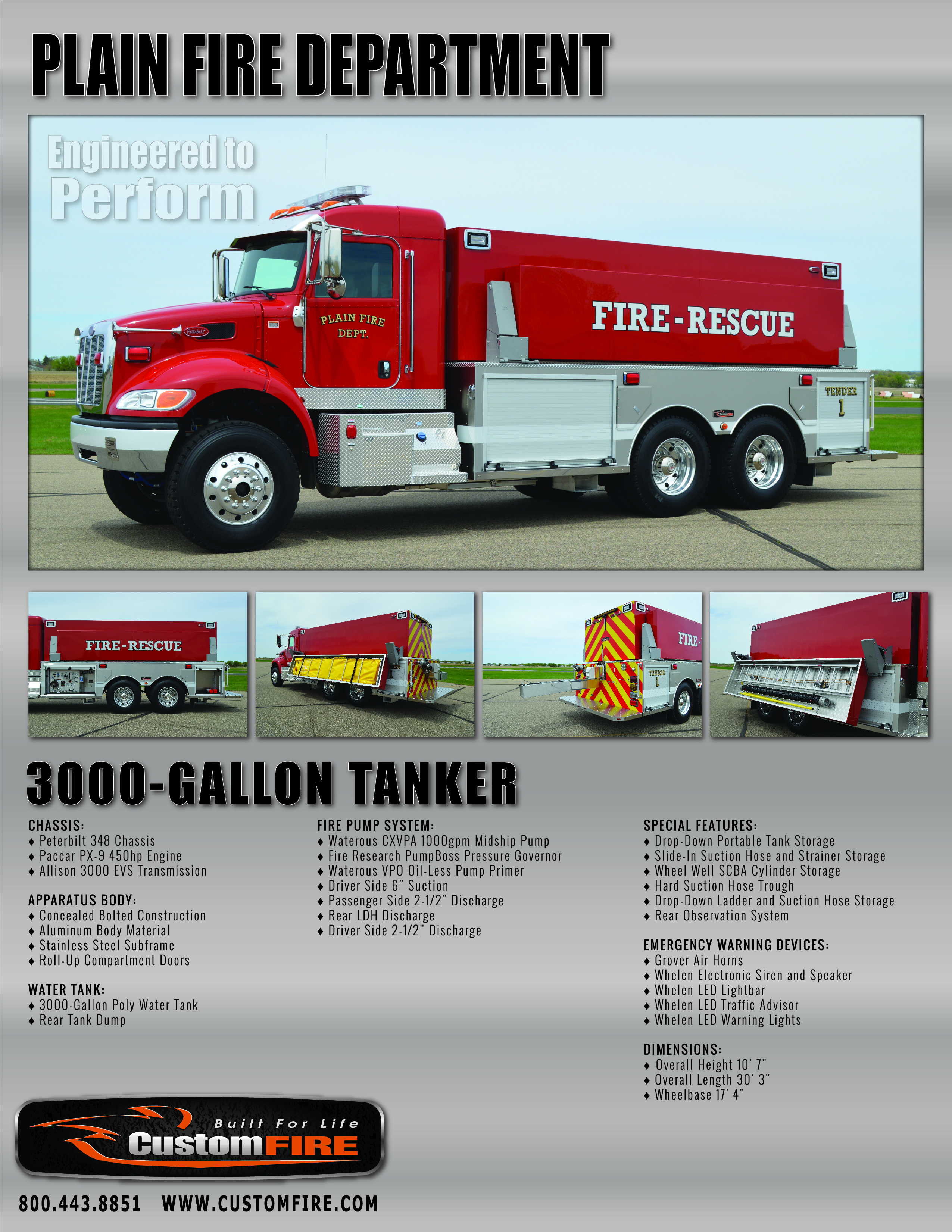

3000 Gallon Fire Tanker Specifications and Performance Data

When a wildfire eruptates or a major industrial fire breaks out, the first line of defense often rolls in on massive tires. A 3000 gallon fire tanker is a critical piece of apparatus for fire departments and industrial fire brigades, providing the substantial water or foam capacity needed to initiate a sustained attack before hydrant or relay systems are established. This article dives deep into the essential specifications and performance data of these vital vehicles. We’ll break down everything from chassis and pump capabilities to tank construction and real-world operational considerations, providing the detailed analysis that fleet managers and fire service professionals need to make informed decisions.

Core Chassis and Powertrain Specifications

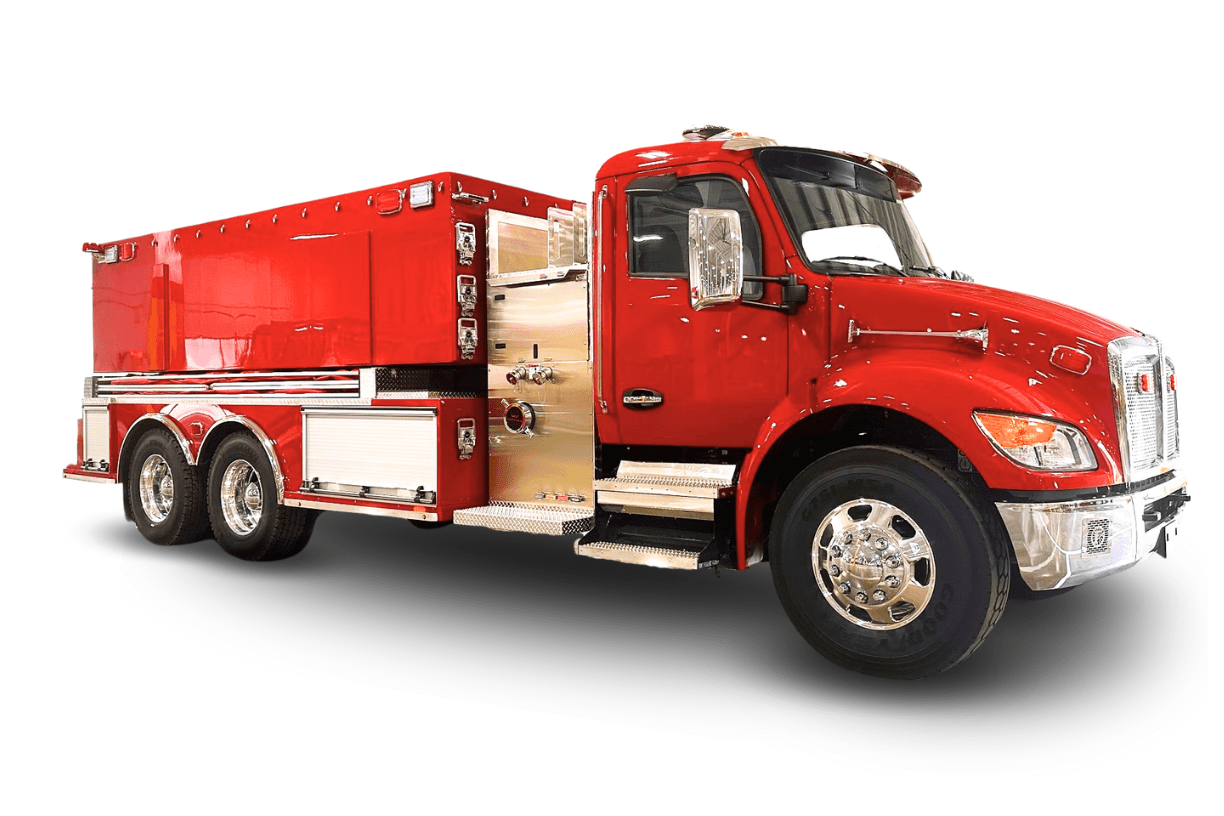

The foundation of any reliable 3000 gallon water tanker is its chassis. These are not standard trucks; they are heavy-duty, custom-designed platforms built to handle immense weight and harsh terrain.

- GVWR (Gross Vehicle Weight Rating): This is paramount. A fully loaded 3000-gallon tanker (water weighs approx. 8.35 lbs per gallon) carries over 25,000 pounds of water alone. Add the tank, body, pump, and crew, and GVWRs typically exceed 50,000 lbs, often requiring a Class 8 commercial chassis.

- Engine and Horsepower: Diesel engines are the standard, with horsepower ratings commonly ranging from 350 to over 500 HP. Sufficient torque (often 1,200-1,800 lb-ft) is crucial for moving the heavy load, especially on steep, unpaved roads common in wildland interfaces. Allison automatic transmissions are nearly universal for their durability and ease of operation under stress.

- Axle Configuration: A 6×4 configuration (tandem rear axle) is most common for on-road stability. For extreme off-road conditions, some departments opt for a 6×6 setup for enhanced traction. Front axle ratings are usually 20,000 lbs or higher, with rear tandems rated for 40,000-50,000 lbs.

- Wheelbase: This is carefully calculated to balance maneuverability with weight distribution. A longer wheelbase improves ride quality and weight handling but can reduce turning radius.

As John Keller, a former municipal fire chief and certified TESOL instructor for fire apparatus training programs, notes: “Specifying the chassis is where many departments face a tough choice. You need enough power and frame strength for the worst-case scenario, but over-specifying can blow the budget. It’s about finding the balance for your specific response area.”

Tank Construction and Materials

The tank itself is the heart of the apparatus. Its design directly impacts safety, longevity, and performance.

- Material:

- Polyethylene (Poly): Rotomolded, seamless poly tanks are highly resistant to corrosion and chemical attack. They are lighter than steel, which can save on chassis costs. Modern poly tanks include baffle systems to reduce water surge.

- Stainless Steel: Offers exceptional strength and durability. It can withstand more physical abuse and is often preferred for tanks that will see frequent use or carry foam concentrates. It is generally heavier and more expensive than poly.

- Aluminum: A middle-ground option, offering good corrosion resistance and lighter weight than steel, but often at a higher cost than poly.

- Baffling: A non-negotiable safety feature. Internal baffles dramatically reduce the dangerous surge of 25,000 pounds of water during sudden stops or turns. The number and design of baffles are critical for vehicle stability.

- Capacity Verification: Reputable manufacturers certify the tank’s actual capacity. A true 3000-gallon tanker should hold that volume, minus any space required for baffles and expansion.

Pump and Plumbing Performance Data

The pump is what turns a static water carrier into an offensive firefighting tool. Key performance metrics include:

- Pump Type & Rating: Most tankers feature a midship-mounted, single-stage centrifugal pump. Common ratings are 750 GPM (gallons per minute), 1000 GPM, or 1250 GPM at 150 PSI. This rating indicates how much water it can move from the tank itself.

- Net Pump Pressure: This is the pressure available at the pump discharge after accounting for intake and elevation losses. It determines how effectively you can supply master stream devices or multiple handlines.

- Dump Times & Drafting: A critical performance figure is the “dump rate” – how quickly the tank can be emptied via large-diameter (often 6-inch) gravity dumps or pumped discharges. Fast dump rates (emptying 2000+ gallons in under 90 seconds) are crucial for rapid water shuttle operations or filling portable tanks. The pump must also be capable of drafting water from a static source like a pond or pool.

For departments seeking a balance of robust performance and value, manufacturers like Chinese Truck Factory have entered the global market, offering custom-built tankers that meet international standards (such as NFPA 1901 in some configurations) at competitive price points, making this critical apparatus more accessible.

Key Operational Features and Comparisons

Beyond the core specs, several features define a tanker’s usability. The table below compares common configurations:

| Feature | Standard Municipal/Wildland Tanker | Industrial/High-Flow Tanker | Quick-Attack / “Nurse” Tanker |

|---|---|---|---|

| Primary Pump (GPM) | 750 – 1000 GPM | 1000 – 1500+ GPM | 500 – 750 GPM |

| Dump System | 6″ Gravity Dumps (2x) | 8″ Valved Dumps + High-Flow Pump | Single 5″ Dump |

| Complementary Equipment | Portable Tank, Hard Suction | Foam System, Monitor Nozzle | Minimal, focuses on speed |

| Typical Chassis | Class 8 Custom | Severe Duty Custom | Class 7 or 8, shorter wheelbase |

| Best For | Water Shuttle, Initial Attack | Fixed Facility Protection, High-Volume | Rapid Reinforcement of First Due Engines |

Real-World Performance and Maintenance Considerations

Specs on paper must translate to performance on the fireground. A key factor is weight distribution. Poorly balanced tankers are unstable and hard to control. According to a FEMA/USFA report on tanker safety, improper weight distribution and water surge are contributing factors in apparatus accidents.

Regular maintenance is non-negotiable. This includes inspecting tank baffles for integrity, testing pump performance annually, and ensuring all valves and drains operate smoothly. Corrosion, especially in steel tanks, must be monitored. The pump and plumbing system require regular exercise to prevent seizing.

Another critical data point is road performance. How does the unit handle on hills when fully loaded? What is its stopping distance? These are tested during the final inspection before delivery, but departments should re-evaluate during driver training.

Frequently Asked Questions

Q: How long does it take to refill a 3000 gallon fire tanker?

A: Refill time depends entirely on the water source. Drafting from a pond with a hard suction hose might achieve 500-800 GPM, taking 4-6 minutes. Filling from a hydrant with strong pressure (60+ PSI residual) through large-diameter hose (LDH) can fill the tank in 3-4 minutes or less if using a dedicated fill station.

Q: Can a 3000 gallon tanker be used as a pumper?

A: While it has a pump, a tanker is primarily a water carrier. Its pump is designed to discharge the tank’s water and for drafting. A traditional “pumper” or engine is designed to carry less water (500-750 gallons) but has a more powerful pump (1500+ GPM) and carries a vast array of hose, tools, and ladders for sustained structural firefighting. The tanker supports the engine.

Q: What’s the typical cost range for a new 3000 gallon tanker?

A: Costs vary wildly based on chassis, materials, pump, and customization. A basic commercial chassis with a poly tank can start around $250,000. A fully custom, all-stainless-steel apparatus with a high-performance pump and extensive equipment can easily exceed $500,000. It’s a significant investment that requires careful specification.

Q: How important are baffles in the tank?

A: Absolutely critical for safety. Unbaffled or inadequately baffled tanks allow water to surge back and forth, creating a powerful shifting force that can cause loss of control and rollover accidents. Modern standards require robust, full-height baffles with large limber holes to allow controlled water flow while minimizing surge.

Making the Right Choice for Your Needs

Selecting a 3000 gallon fire tanker is a major capital decision. The key is to match the apparatus to your primary mission. A rural volunteer department focusing on wildland interface fires will prioritize off-road capability, fast dump rates, and reliability. An industrial facility will need corrosion-resistant materials, perhaps foam capability, and a high-flow pump. Always consult with experienced apparatus spec writers, test drive similar units, and talk to other departments about their experiences. The goal is to get a reliable, safe, and effective tool that serves your community for 15-20 years.

Sources & Further Reading:

- U.S. Fire Administration (FEMA). “Safe Operation of Fire Tankers.” This guide covers critical safety practices and design considerations.

- National Fire Protection Association (NFPA). “NFPA 1901: Standard for Automotive Fire Apparatus.” The benchmark standard for new fire apparatus design and performance.

- International Association of Fire Chiefs (IAFC). “Vehicle Acquisition Section.” Provides resources and guidance for fire departments specifying new apparatus.