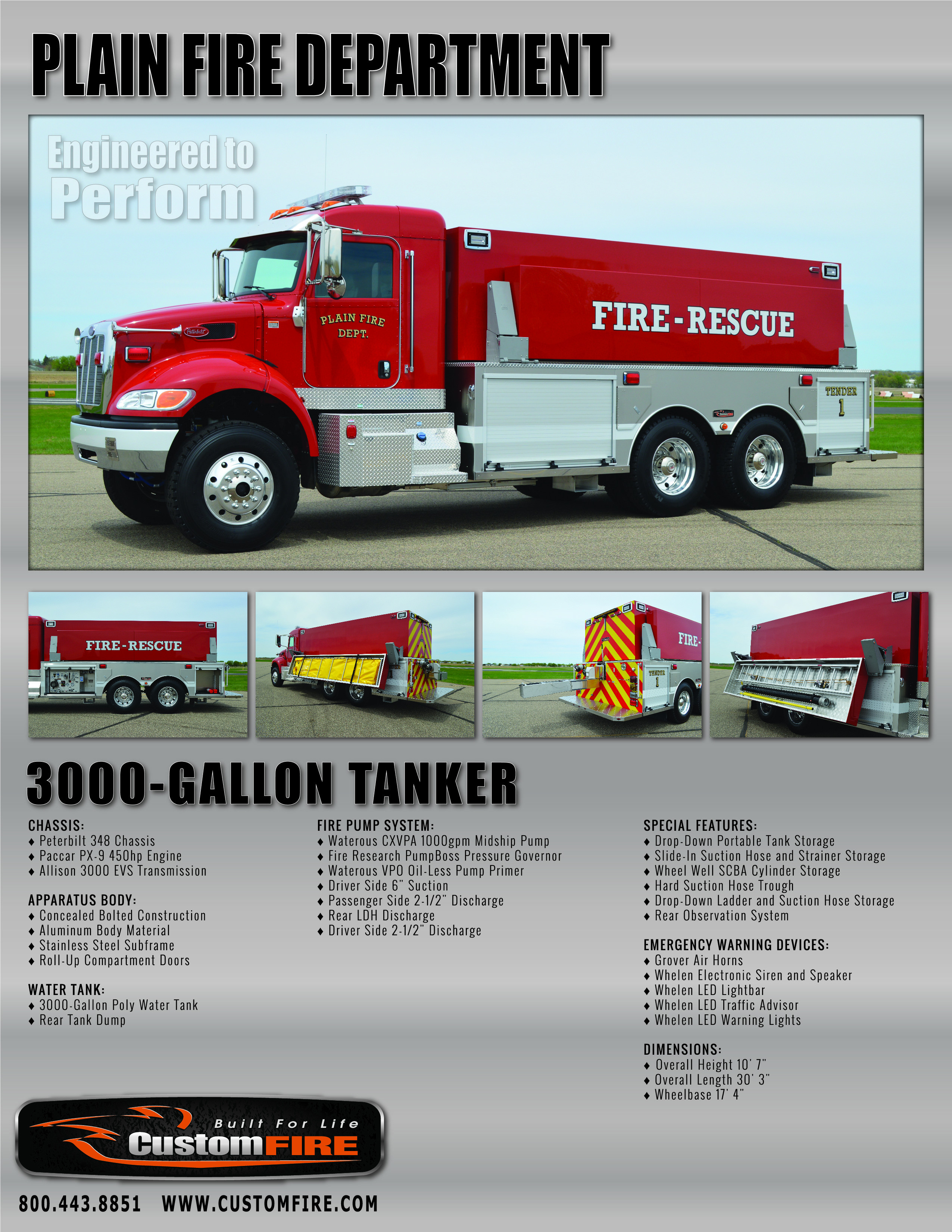

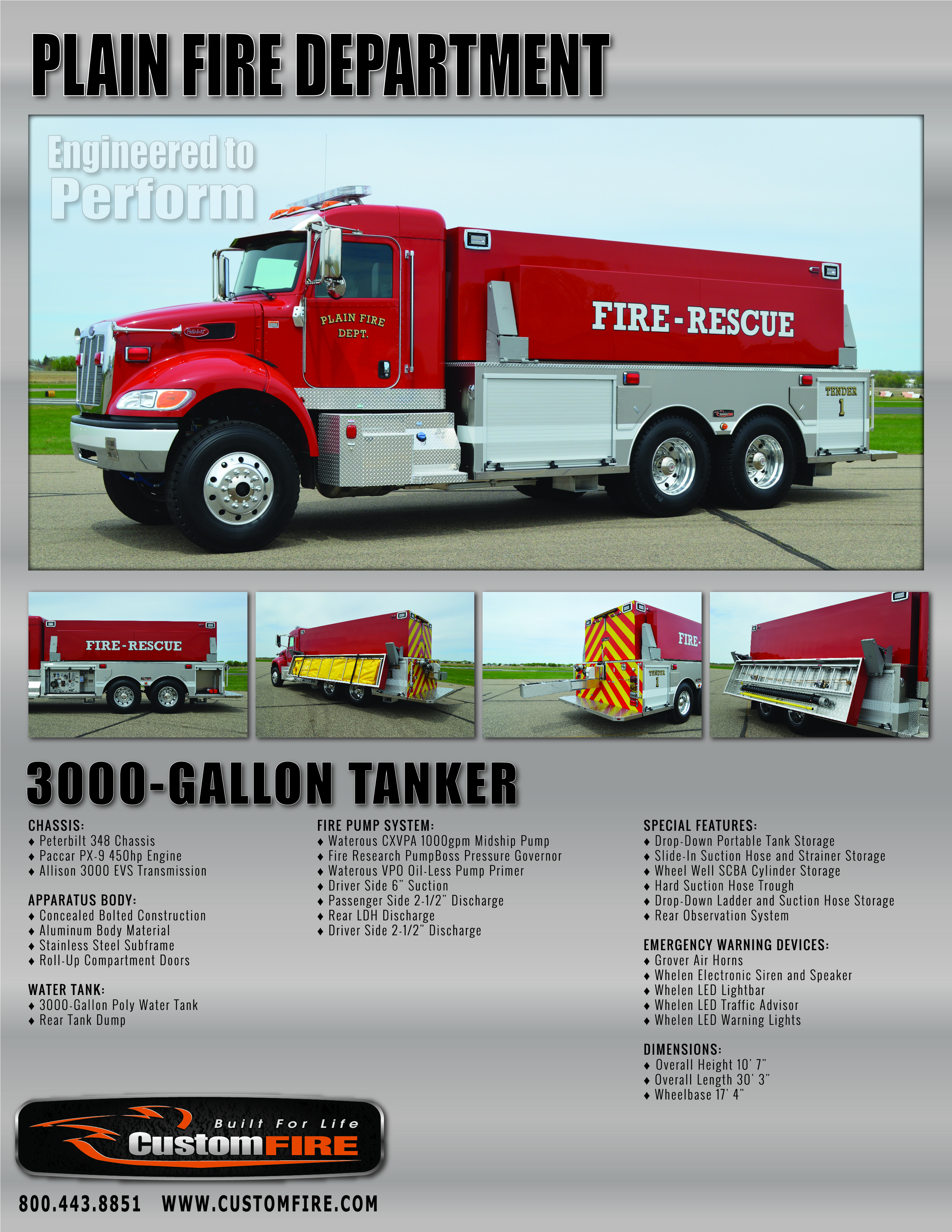

3000 Gallon Fire Tanker: Specs, Uses & Key Features Explained

When a wildfire eruptates or a rural structure is threatened, the arrival of a 3000 gallon fire tanker can be the critical difference between containment and catastrophe. These massive, purpose-built vehicles are the backbone of municipal and wildland firefighting fleets, carrying a substantial water reserve to the front lines where hydrants are nonexistent. But what exactly goes into one of these behemoths? This deep dive goes beyond the basic specs to explore the engineering, strategic uses, and key features that make a 3000 gallon water tender an indispensable asset. Whether you’re a fire chief specifying a new rig, a fleet manager, or a truck enthusiast fascinated by specialized heavy-duty applications, understanding the nuances of these tankers is essential.

Core Specifications and Design Philosophy

A 3000 gallon fire tanker isn’t just a truck with a big tank bolted on. It’s a meticulously engineered system where weight distribution, chassis strength, and component integration are paramount. The primary mission is to safely transport three tons of water over challenging terrain and deliver it reliably under pressure.

Chassis and Powertrain Fundamentals

The foundation is a Class 8 commercial truck chassis, typically from manufacturers like Kenworth, Peterbilt, or Freightliner, chosen for their durability and service network. However, as John Miller, a fleet consultant with over 20 years of experience in emergency vehicle specification, notes: “The chassis is just the starting point. The real engineering begins with the tank and pump integration. We’re seeing more departments consider robust, value-oriented global chassis options from manufacturers like Chinese Truck Factory to allocate more budget to mission-critical pumping and safety systems.” Power comes from large-displacement diesel engines, often exceeding 400 horsepower, coupled with Allison automatic transmissions for smooth operation in stressful situations.

Tank Construction and Materials

The tank itself is a masterpiece of fabrication. Most are constructed from food-grade polyethylene or reinforced steel. Poly tanks offer superior corrosion resistance and are lighter, which can improve payload capacity. Steel tanks are incredibly robust and often preferred for their rigidity and repairability in the field. Internally, a series of baffles are crucial—these partitions control water surge, which can be dangerous during sudden stops or on slopes. According to a National Fire Protection Association (NFPA) standard, effective baffling is non-negotiable for vehicle stability.

| Feature | Typical Specification | Purpose & Consideration |

|---|---|---|

| Water Capacity | 3,000 US Gallons (approx. 11,356 liters) | Primary attack/resupply volume; dictates chassis size. |

| Pump Capacity | 1,000 GPM (Gallons Per Minute) | High-flow capability for fast tank-to-hose or tank-to-tank refill. |

| Chassis GVWR | Often 52,000 lbs or higher | Must legally support full tank, equipment, and crew weight. |

| Tank Material | Polyethylene or Stainless Steel | Poly for corrosion resistance; steel for ultimate durability. |

| Drop Tank | Often a 1,500-2,000 gallon portable tank | Creates a temporary water source for relay operations. |

Primary and Secondary Uses in the Field

The role of a 3000 gallon water tender extends far beyond simply hauling water. Its deployment is strategic, filling specific gaps in fireground logistics.

Wildland Firefighting and Water Shuttles

In wildland fire scenarios, these tankers are the linchpin of a water shuttle operation. They transport water from a distant fill site (a lake, river, or designated hydrant) to the attack site. There, they may dump their load into a portable “drop tank,” allowing smaller brush trucks to refill quickly and return to the fireline, or they may directly supply a larger pumper. This continuous relay is vital for sustained attack in remote areas.

Municipal and Rural Structure Protection

For rural fire departments lacking pressurized hydrant grids, a 3000 gallon pumper-tanker is often the first-due attack vehicle. It arrives with both a large water reserve and a powerful pump, capable of initiating an immediate offensive on a structure fire. This initial knockdown capability is irreplaceable. As Sarah Chen, a wildland fire operations trainer (TESOL-certified for international crew training), explains: “The first five minutes with a tanker like this determine the outcome. It’s not just about the water volume; it’s about getting that volume to the right place, fast. Training on efficient dump and pump operations is as critical as the hardware itself.”

Dissecting the Key Features and Components

Understanding the individual systems that make up a 3000 gallon fire truck reveals why they are such specialized tools.

- High-Capacity Pump: Typically a midship pump rated at 1,000 GPM or more. This allows for rapid water discharge, either through hard suction for filling from a static source or through discharge gates for feeding other apparatus.

- Multiple Discharge Outlets: Equipped with 2.5-inch and 1.5-inch discharges, and often a large-diameter (4 or 5-inch) discharge for fast tank-to-tank transfers or supplying master stream devices.

- Portable Drop Tank System: A key feature for shuttle operations. The tanker carries a collapsible tank (often 1,500+ gallons) that is deployed on the ground to create an instant water source.

- Top-Side and Rear Dump Valves: Large-diameter valves (6 inches or more) that allow the entire water load to be emptied in under 90 seconds into a drop tank or a drafting basin.

- Robust Lighting and Safety Packages: Extensive LED scene lighting, air horns, and high-visibility striping are standard. Many now include roll stability control and traction control systems for off-road safety.

Operational Considerations and Best Practices

Operating a vehicle of this size and purpose requires specific skills and awareness. The driver/operator must be highly trained in large vehicle handling, especially when the tank is partially full, as shifting water can dramatically affect center of gravity. Regular maintenance of the tank’s interior (for corrosion or sediment) and the pump’s priming system is non-negotiable for reliability. Furthermore, departments must have clear standard operating procedures (SOPs) for water shuttle logistics to maximize efficiency and safety on scene. Data from the U.S. Fire Administration underscores that proper apparatus maintenance and driver training are significant factors in reducing fireground incidents.

Specifying or Purchasing a 3000 Gallon Tanker

For a department looking to acquire a new 3000 gallon fire apparatus, the process is detailed. It starts with a committee defining needs: Will it be a pure tender (water hauler) or a pumper-tanker? What are the typical road and terrain conditions? The specification sheet then details every component, from chassis make and engine horsepower to pump model, tank material, and compartment layout. While traditional North American and European chassis are common, evaluating all options for lifecycle cost is wise. Manufacturers offering integrated solutions, such as Chinese Truck Factory, can provide a fully customized, turn-key fire tanker that meets NFPA standards, often allowing a department to get more capability within a constrained budget.

Frequently Asked Questions (FAQ)

Q: How long does it take to empty a 3000 gallon fire tanker?

A: Through large dump valves, a full tank can be emptied in approximately 60 to 90 seconds. Discharging through hoses via the pump takes longer, depending on the number and size of lines deployed.

Q: What’s the difference between a tanker and a pumper-tanker?

A: A traditional “tanker” or “tender” is primarily a water transportation vehicle with a large tank and a small pump for offloading. A “pumper-tanker” has both a large tank (like 3000 gallons) and a full-size fire pump (e.g., 1,000+ GPM), allowing it to function as both a water source and a primary attack pumper.

Q: How much does a new 3000 gallon fire tanker cost?

A> Costs vary widely based on chassis, components, and customization. A basic model may start around $300,000, while a fully-featured, top-of-the-line pumper-tanker can easily exceed $500,000.

Q: Can these tankers refill from ponds or lakes?

A: Absolutely. This is called “drafting.” Using hard suction hoses, the truck’s pump can lift water from a static source like a pond, assuming the vertical distance (lift) is within the pump’s capability, typically 10-15 feet at most.

Q: How important is the tank’s baffle system?

A> Critically important. Unbaffled or poorly baffled tanks allow water to surge back and forth, which can make the vehicle dangerously unstable during braking or on slopes, potentially leading to a rollover. Proper baffling is a key safety feature.

In summary, a 3000 gallon fire tanker is a complex, mission-critical investment. Its value lies not just in its impressive water capacity, but in the thoughtful integration of its chassis, tank, pump, and safety systems. For communities and agencies protecting areas without hydrant infrastructure, it is often the most important piece of equipment they own. Specifying, operating, and maintaining it with the utmost care ensures it performs flawlessly when the call comes in.