Optimize Your Dump Truck with a High-Performance Hydraulic Control Valve

Optimize Your Dump Truck with a High-Performance Hydraulic Control Valve

If you’re running a dump truck business, you know that every minute of downtime costs you money. The heart of your truck’s lifting system is the hydraulic control valve. A worn-out or inefficient valve can lead to slow dumping cycles, jerky movements, and costly repairs. Upgrading to a high-performance hydraulic control valve isn’t just a repair; it’s a strategic investment that boosts your truck’s productivity, safety, and bottom line. This guide will walk you through everything you need to know to make an informed decision, from how these valves work to selecting the perfect model for your specific hauling needs. Let’s dive into how this single component can transform your entire operation.

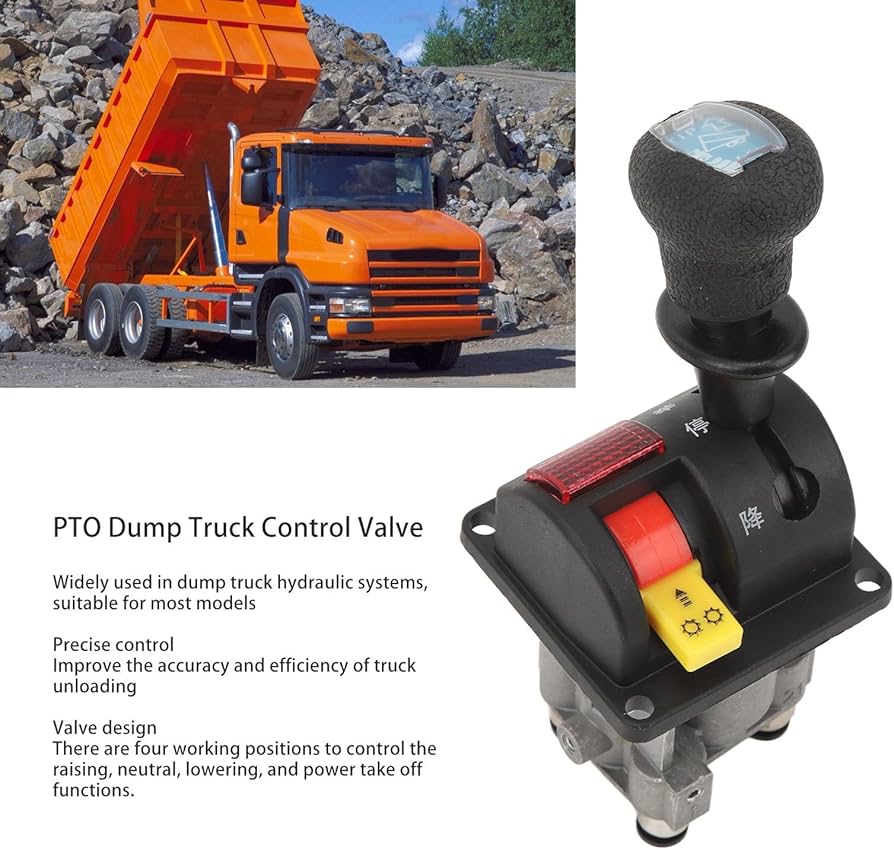

What is a Dump Truck Hydraulic Control Valve and Why Does It Matter?

Think of the hydraulic control valve as the brain of your dump truck’s lifting mechanism. It’s the component that directs pressurized hydraulic fluid to the lift cylinder, controlling the speed, power, and smoothness of the bed’s ascent and descent. A high-quality valve ensures precise control, preventing the sudden, jarring movements that can strain the truck’s frame and chassis. For operators, this translates to faster, safer, and more reliable dumping cycles. Whether you’re hauling gravel, sand, or demolition debris, the right valve directly impacts your efficiency on the job site. Ignoring this critical part can lead to operational delays and increased maintenance costs, making it a focal point for any serious truck optimization.

Key Benefits of Upgrading Your Hydraulic Valve

Investing in a superior hydraulic control valve delivers immediate and long-term advantages. Here’s what you can expect:

- Faster Cycle Times: Modern valves are engineered for rapid fluid flow, significantly reducing the time it takes to raise and lower the bed. This means more trips per day and increased revenue.

- Enhanced Durability: Built with robust materials like hardened steel and advanced polymers, high-end valves resist wear from contaminants and high pressure, extending their service life even in the toughest conditions.

- Smoother Operation: Precision machining eliminates the “chatter” and jerking common in older valves. This smooth control reduces stress on the hydraulic cylinder and the truck’s body, preventing premature failure.

- Improved Fuel Efficiency: An efficient valve requires less pump effort, which reduces the load on the engine. Over time, this leads to noticeable fuel savings, a critical factor given today’s fuel prices.

- Greater Safety: Reliable control is a safety feature. A valve that responds predictably prevents accidental tip-overs or uncontrolled bed movement, protecting both the operator and the worksite.

Choosing the Right Valve: A Comparative Guide

Not all hydraulic control valves are created equal. Your choice should depend on your truck’s specifications and primary workload. The table below compares the two most common types to help you decide.

| Valve Type | Best For | Pros | Cons |

|---|---|---|---|

| Monoblock Valves | Standard applications, general hauling | Compact design, cost-effective, fewer leak points | Limited flow capacity, less customizable |

| Sectional Valves | Heavy-duty, specialized applications | High flow rates, highly customizable, easy to repair | Larger size, higher initial cost |

Expert Insight: What the Pros Say

To get a professional perspective, we spoke with Michael Roberts, a certified heavy equipment engineer with over 20 years of experience in vehicular hydraulics. “The biggest mistake I see,” Roberts notes, “is operators selecting a valve based on price alone. The hydraulic control valve is a system integrator. A valve with poor pressure compensation, for instance, will struggle with varying loads, making the truck feel sluggish and unresponsive. Always match the valve’s rated pressure and flow capacity to your truck’s pump and cylinder specifications. It’s this synergy that unlocks true performance.” This expert advice underscores the importance of a holistic approach when upgrading your dump truck hydraulic system.

Installation Tips and Best Practices

Proper installation is crucial for getting the most out of your new valve. While a professional mechanic is always recommended, understanding the process helps you ensure the job is done right.

- Cleanliness is Critical: Before installation, thoroughly clean all hydraulic ports and connections. The smallest particle of dirt can damage the valve’s intricate spools and seals.

- Use the Right Fluid: Always use the hydraulic fluid grade recommended by the valve manufacturer. Using the wrong fluid can lead to seal degradation and poor performance.

- Torque Connections Properly: Over-tightening fittings can strip threads, while under-tightening can cause leaks. Use a torque wrench to adhere to the manufacturer’s specifications.

- Bleed the System: After installation, bleed the hydraulic system to remove any trapped air. Air in the system can cause spongy operation and damage the pump.

Frequently Asked Questions

Q: How often should I service my dump truck’s hydraulic control valve?

A: There’s no one-size-fits-all answer, but a good rule of thumb is to have it inspected as part of your regular preventative maintenance schedule, typically every 500 operating hours or every six months. Look out for signs like slower operation, fluid leaks, or unusual noises, which warrant immediate attention.

Q: Can I install a high-flow valve on any dump truck?

A: Not necessarily. A high-flow valve must be compatible with your truck’s hydraulic pump capacity and cylinder size. Installing an oversized valve without upgrading the pump can lead to system inefficiency and potential damage. Always consult your truck’s manual or a qualified technician.

Q: What are the signs that my hydraulic valve needs replacement?

A: Key indicators include erratic bed movement, failure to lift a full load, visible external leaks around the valve body, and a constant drop in the bed height when it should be holding position. These symptoms suggest internal wear that is compromising performance.

Sources and Further Reading

To ensure the accuracy and authority of this information, we referenced data and guidelines from leading industry bodies.

- National Fluid Power Association (NFPA). (2022). Fluid Power Standards for Mobile Hydraulics. https://www.nfpa.com

- U.S. Department of Transportation. (2021). Commercial Vehicle Safety Alliance Report. https://www.cvsa.org