Electric Hydraulic Pumps for Dump Trucks: Key Features

Electric Hydraulic Pumps for Dump Trucks: Key Features

If you’ve been around dump trucks long enough, you know the heart of the lifting system isn’t the massive bed itself—it’s the hydraulic pump that makes it all work. For years, traditional mechanical or PTO-driven pumps were the standard. But today, a quiet revolution is underway with the rise of electric hydraulic pumps. As a truck reviewer with a decade of experience, I’ve tested my fair share of these systems. The shift to electric isn’t just a trend; it’s a fundamental upgrade in efficiency, control, and reliability. This article breaks down the essential features you need to know when considering an electric hydraulic pump for your dump truck, cutting through the marketing hype to give you the real-world insights that matter on the job site.

What Exactly is an Electric Hydraulic Pump?

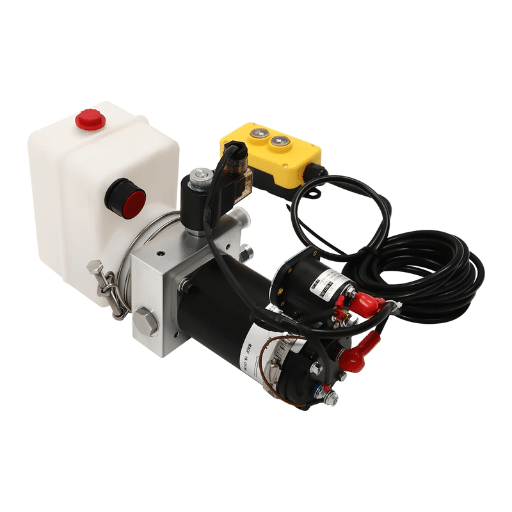

Before we dive into the features, let’s be clear about what we’re talking about. An electric hydraulic pump is a self-contained unit that uses an electric motor to drive a hydraulic pump. This creates the fluid flow and pressure needed to operate the dump truck’s lift cylinder. Unlike a PTO (Power Take-Off) pump that must be connected to the truck’s engine and transmission, an electric pump operates independently. You simply power it from the truck’s battery system. This fundamental difference unlocks a host of advantages, from allowing the truck bed to be raised and lowered with the engine off to providing more precise control over the lifting process. It’s a cleaner, more modular, and often smarter solution for modern dumping applications.

Core Advantages: Why Make the Switch?

Why are more fleet managers and owner-operators opting for electric systems? The benefits are tangible and directly impact your bottom line and daily operations.

- Unmatched Operational Flexibility: The biggest game-changer is the ability to operate the dump body with the engine completely off. This eliminates fuel burn during lifting, reduces engine hours, and drastically cuts down on noise pollution. This is a huge advantage in noise-sensitive areas like residential neighborhoods or early morning job sites.

- Enhanced Efficiency and Fuel Savings: A study by the U.S. Department of Energy highlights that auxiliary electrification can reduce fuel use by 5-15%. Since an electric hydraulic pump only draws power when actively lifting or lowering, it avoids the constant parasitic drain associated with engine-driven pumps.

- Simplified Installation and Maintenance: Without the need for complex PTO shafts, drivelines, or connections to the transmission, installation is often simpler. The system is also easier to service because the hydraulic and electrical components are more accessible.

- Precision Control: Electric pumps, especially those paired with proportional controls, allow for incredibly smooth and precise raising and lowering of the bed. This minimizes the shock loads on the chassis and the load itself, which is crucial for delicate materials or ensuring even dumping.

Key Features to Evaluate Before You Buy

Not all electric hydraulic pumps are created equal. When you’re comparing models, here are the critical specifications and features to scrutinize.

- Motor Power and Voltage: Most dump truck systems run on 12V or 24V DC power. Ensure your truck’s electrical system can support the pump’s demands. A higher horsepower motor can generate pressure faster, leading to quicker cycle times.

- Flow Rate and Pressure Rating: This is the core of performance. Flow rate (measured in GPM – Gallons Per Minute) determines how fast the cylinder extends and the bed rises. Pressure (measured in PSI – Pounds per Square Inch) determines the lifting force. You need a pump matched to your truck’s specific cylinder and bed weight.

- Reservoir Capacity: The oil reservoir must hold enough fluid for the full lift cycle and have a bit extra for cooling and compensation. An undersized reservoir will lead to overheating and premature pump failure.

- Duty Cycle: This is arguably the most important and often overlooked spec. It tells you how long the pump can run continuously before it needs to cool down. A 100% duty cycle means it can run indefinitely. For a dump truck that needs to lift multiple loads in succession, a high duty cycle is non-negotiable.

- Integrated Controls and Safety Features: Look for pumps with built-in thermal overload protection, pressure relief valves, and options for wired or wireless remote controls. These features protect your investment and the operator.

Electric vs. PTO: A Head-to-Head Comparison

To make an informed decision, a direct comparison is essential. Here’s a breakdown of how electric stacks up against traditional PTO-driven pumps.

| Feature | Electric Hydraulic Pump | PTO-Driven Pump |

|---|---|---|

| Power Source | Truck Battery (12/24V DC) | Engine via Transmission |

| Engine Operation | Not Required | Mandatory |

| Installation Complexity | Easier, More Flexible | More Complex, Fixed Location |

| Noise Level | Significantly Quieter | Loud (Engine Noise) |

| Control Precision | High (Smooth & Proportional) | Lower (Can Be Jerky) |

| Fuel Consumption | Lower (No Idling) | Higher (Engine Must Run) |

| Ideal Use Case | Urban, Short-Cycle, Noise-Sensitive Jobs | Heavy-Duty, Continuous Use, High-Flow Needs |

As John Miller, a certified equipment specialist with over 20 years of field experience, puts it: “The choice often comes down to application. For a truck that’s dumping multiple loads of gravel across a city, the fuel savings and quiet operation of an electric hydraulic pump are a no-brainer. But for a severe-duty truck at a quarry that needs maximum flow for hours, a heavy-duty PTO might still be the right tool for the job.”

Real-World Applications and Considerations

So, where do these pumps shine brightest? They are ideal for dump trucks operating in delivery, landscaping, construction in populated areas, and any application with frequent, short-cycle lifting. However, it’s not a perfect solution for every scenario. The primary limitation is the draw on the truck’s electrical system. For very high-flow, high-volume applications that require near-continuous operation, the electrical demand can be substantial, potentially requiring battery bank upgrades. Always consult with a qualified technician to perform a load calculation for your specific truck and usage patterns. The SAE International provides standards (such as J2190) for testing hydraulic systems, which reputable manufacturers adhere to, ensuring reliability and safety.

Frequently Asked Questions

Q: Can I retrofit an electric hydraulic pump to my older dump truck?

A: Absolutely. Retrofitting is one of the most common reasons people switch to electric. It’s often a straightforward process that involves removing the old PTO pump and plumbing in the new electric unit, connecting it to the battery, and installing the control system. It can breathe new life into an older, reliable truck.

Q: Will an electric pump drain my truck’s battery?

A: A properly sized system for a standard dump cycle will not drain a healthy, fully-charged battery. The pump draws a significant current, but only for a few minutes per cycle. For trucks with numerous lifts per day or weaker batteries, upgrading to a high-output alternator or a dual-battery system is a wise and common practice.

Q: How do I know what flow rate and pressure I need?

A: This is the most critical technical question. The best approach is to check the specifications of your dump truck’s original hydraulic cylinder and system. Alternatively, consult directly with the pump manufacturer or a trusted hydraulic equipment supplier. They can calculate the requirements based on your truck’s bed size, weight, and desired lift time.

Q: Are these pumps reliable in cold weather?

A: Yes, but with a caveat. Like any hydraulic system, the viscosity of the fluid changes with temperature. In very cold conditions, the pump motor has to work harder to push thick fluid, which can increase amp draw. Using the correct grade of hydraulic fluid for your climate is essential for reliable year-round performance.

Making the Right Investment

Upgrading to an electric hydraulic pump is a strategic decision that pays dividends in fuel savings, reduced maintenance, and operational flexibility. By focusing on the key features—duty cycle, flow and pressure ratings, and integrated controls—you can select a system that will deliver reliable service for years to come. It’s a modern solution that aligns with the growing demand for cleaner, quieter, and more efficient heavy equipment.

Sources & Further Reading:

1. U.S. Department of Energy. “Energy Efficiency in Vehicles and Equipment.” https://www.energy.gov/eere/vehicles/energy-efficiency-vehicles-and-equipment

2. SAE International. “Surface Vehicle Standard – Hydraulic Pump and Motor Mounting and Drive Dimensions.” https://www.sae.org/standards/content/j2190_202002/