PTO Water Pumps for Trucks: Efficient Solutions for Water Hauling

PTO Water Pumps for Trucks: Efficient Solutions for Water Hauling

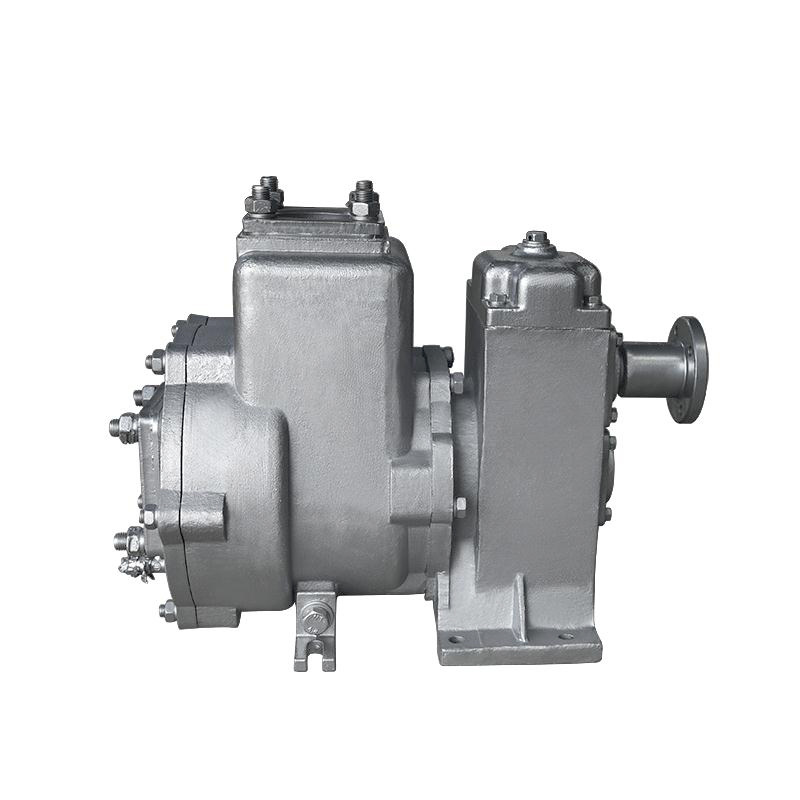

If you’re in the business of moving large volumes of water, whether for agriculture, construction, or fire suppression, you know that efficiency is everything. The heart of any effective water hauling system is the pump, and for truck-based operations, nothing beats the raw power and reliability of a Power Take-Off (PTO) water pump. Unlike engine-driven or electric models that demand separate power sources, a PTO pump for trucks leverages your truck’s existing engine power through the transmission. This direct connection creates a remarkably efficient and self-contained solution for demanding water transfer tasks. This guide will dive deep into why a PTO water pump is often the smartest choice, how to select the right one, and what you need to know to keep it running strong for years.

Why Choose a PTO-Driven Pump for Your Water Hauling Needs?

The primary advantage of a truck PTO water pump is its seamless integration with your vehicle’s powertrain. By engaging the PTO, you directly harness a portion of the engine’s horsepower to drive the pump. This eliminates the need for a separate motor, saving on fuel, weight, and complex installation. For operators who need to move thousands of gallons in a single trip, this efficiency translates directly into lower operating costs and faster job completion. The simplicity of the system also means there are fewer components that can fail, leading to greater uptime and reliability in the field. When your livelihood depends on moving water from point A to point B without hiccups, the robust nature of a PTO-driven system is a significant benefit.

Key Factors When Selecting a Truck PTO Water Pump

Not all PTO water pumps are created equal. Choosing the right model requires a careful look at your specific operational demands. The two most critical specifications are flow rate (measured in gallons per minute, or GPM) and pressure (measured in pounds per square inch, or PSI).

- Flow Rate (GPM): Determine how quickly you need to fill or empty your tank. A higher GPM is crucial for large-scale dewatering or filling big tanks rapidly.

- Pressure (PSI): If you need to push water over long distances, uphill, or through spray nozzles, a pump with higher pressure capabilities is essential.

- Pump Construction: Look for pumps with durable housings like cast iron or aluminum and impellers made from reinforced composites or stainless steel to resist abrasion and corrosion.

- PTO Shaft Compatibility: Ensure the pump’s input shaft and connection type match your truck’s PTO output. A mismatch can lead to costly damage.

PTO Pump vs. Electric Pump: A Head-to-Head Comparison

How does a PTO pump stack up against a popular alternative like an electric pump? The following table breaks down the key differences to help you make an informed decision.

| Feature | PTO Water Pump | Electric Water Pump |

|---|---|---|

| Power Source | Vehicle’s engine via transmission | Separate battery or generator |

| Typical Flow Rate | Very High (e.g., 100+ GPM) | Low to Moderate (e.g., 20-60 GPM) |

| Initial Cost | Moderate | Lower |

| Operating Cost | More fuel-efficient for heavy-duty use | Requires separate power source fuel/electricity |

| Best For | High-volume water hauling, industrial use | Smaller tasks, remote operations where truck engine is off |

As Mike Reynolds, a certified equipment specialist with over 15 years of experience in fluid transport systems, notes, “For consistent, high-volume transfer, a PTO water pump is unmatched in its efficiency. It turns your truck into a powerful, mobile pumping station without the added weight and maintenance of a secondary engine.” This expert insight underscores the pump’s core strength for professional applications.

Installation and Maintenance Tips for Longevity

Proper installation is the first step toward a long service life. It’s highly recommended to have a qualified technician handle the installation to ensure the PTO unit is correctly engaged and the pump is securely mounted. Once operational, a simple but consistent maintenance routine is key.

- Prime the Pump: Always ensure the pump is primed (filled with water) before starting to prevent damage from dry running.

- Lubrication: Regularly check and grease the PTO shaft and any fittings as specified in your manual.

- Strainer Check: Use and frequently clean an intake strainer to keep debris from entering and damaging the impeller.

- Winterization: In freezing climates, completely drain the pump after use to prevent cracking from ice expansion.

Real-World Applications: Where Truck-Mounted PTO Pumps Shine

The versatility of these pumps makes them indispensable across several industries. In agriculture, they are used for irrigation, transferring water to remote fields, or emptying collection ponds. Construction sites rely on them for dewatering excavations and supplying water for dust control. According to a 2021 workforce survey by the Associated General Contractors of America, 89% of construction firms report difficulty finding qualified workers, making labor-saving equipment like efficient PTO pumps more valuable than ever. Furthermore, they are critical in firefighting for filling tender trucks from static sources like lakes or pools, and in landscaping for quickly filling large spray rigs.

Answers to Common Queries About PTO Water Pumps

Q: Can I install a PTO water pump on any truck?

A: Not exactly. Your truck must be equipped with a PTO unit on its transmission. Many medium and heavy-duty work trucks have this option, but it’s not standard on all consumer-grade pickups. Check your vehicle’s specifications or consult a dealer.

Q: How much engine power does the PTO pump use?

A: It consumes a portion of the engine’s horsepower. The exact amount depends on the pump’s size and the pressure it’s working against. It’s crucial not to exceed the recommended horsepower rating for your PTO, as outlined in the SAE J2835 standard for PTO interface dimensions, to avoid damaging your transmission.

Q: What is the typical lifespan of a quality PTO water pump?

A> With proper installation, usage, and maintenance, a high-quality PTO water pump can last for thousands of hours. Avoiding dry running, keeping the system clean, and addressing small issues promptly are the biggest factors in maximizing its lifespan.

Sources:

Associated General Contractors of America – 2021 Workforce Survey Report

SAE International – Standard J2835: PTO Interface Dimensions