Diesel Fuel Tanks for Trucks: Capacity & Installation Guide

Diesel Fuel Tanks for Trucks: Capacity & Installation Guide

Choosing the right diesel fuel tank for your truck isn’t just about adding more miles between fill-ups; it’s a critical decision that impacts your vehicle’s range, payload, and overall operational efficiency. Whether you’re a long-haul owner-operator or managing a fleet, understanding fuel tank capacity and the nuances of proper installation is paramount. This comprehensive guide cuts through the noise, offering a clear, step-by-step walkthrough to help you select the ideal tank size and ensure it’s fitted correctly and safely. We’ll dive into the key factors you need to consider, from material choices to the legalities of cross-border travel, empowering you to make an informed choice that perfectly suits your trucking needs.

Understanding Diesel Fuel Tank Capacity

Diesel fuel tank capacity is the total volume of fuel a tank can hold, typically measured in gallons in the United States. It’s the first and most obvious specification truck owners look at. However, the “right” capacity is a balancing act. A larger tank means extended range, which is a godsend for long-haul routes with sparse fueling stations. It can also allow you to buy fuel in bulk when prices are low. Conversely, a larger tank adds significant weight, which can cut into your payload capacity—a crucial factor for maximizing revenue per trip. The average for many Class 8 trucks falls between 125 and 300 gallons, often split between dual saddle-mounted tanks.

| Truck Type / Use Case | Typical Fuel Tank Capacity Range | Primary Consideration |

|---|---|---|

| Regional/Day Cab | 80 – 150 gallons | Weight savings, maneuverability |

| Long-Haul Sleeper | 150 – 300+ gallons | Maximum range, fuel purchasing strategy |

| Heavy Hauler/Oversized Load | 200 – 500+ gallons | Extended operation without support |

| Auxiliary/Transfer Tank | 50 – 150 gallons | Supplemental fuel for remote work |

Key Factors Influencing Your Capacity Choice

Your route and operational patterns are the biggest drivers in choosing a fuel tank size. Ask yourself these questions:

- Mileage and Route Density: How many miles do you run between readily available and competitively priced truck stops? Running through remote areas like parts of Nevada or Texas may necessitate a larger capacity.

- Payload vs. Fuel Weight: Diesel fuel weighs approximately 7 pounds per gallon. A 300-gallon tank full of fuel adds over 2,100 pounds to your truck’s weight. For freight where you’re constantly bumping against weight limits, a slightly smaller tank might be more profitable.

- Fuel Cost Strategy: Some operations leverage large tank capacity to “fuel hunt,” topping off only in states with the lowest fuel taxes.

Materials and Construction: Aluminum vs. Steel

The debate between aluminum and steel diesel fuel tanks is a classic one, and each material has its staunch advocates. The choice significantly impacts durability, maintenance, and cost.

Aluminum Fuel Tanks: The most popular choice for modern over-the-road trucks. Aluminum is naturally corrosion-resistant, which is a massive advantage against road salt and fuel degradation byproducts. They are lighter than steel, contributing to better payload capacity. However, they are generally more expensive upfront and can be more susceptible to physical impact damage.

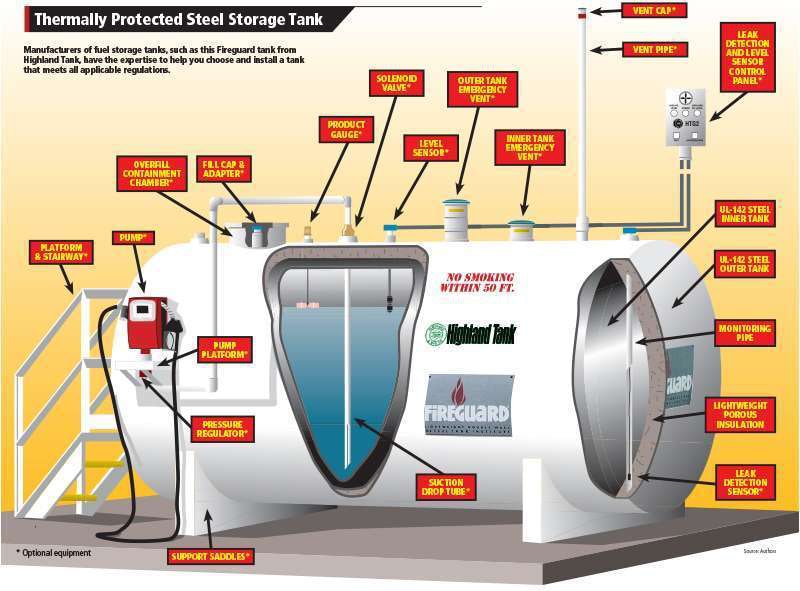

Steel Fuel Tanks: Known for their exceptional durability and ruggedness, steel tanks can take more punishment from rocks and road debris. They are also less expensive to manufacture. The major drawback is their susceptibility to rust and corrosion, especially if the exterior paint is chipped or the interior is exposed to water condensation. Regular inspection and maintenance are critical for steel tank longevity.

A Step-by-Step Guide to Diesel Tank Installation

While a professional installation is always recommended for safety and warranty purposes, understanding the process helps you oversee the work and ensure it’s done correctly. Here’s a breakdown of a typical installation for a replacement saddle tank.

- Safety First & Preparation: Deplete the fuel in the old tank as much as possible. Disconnect the battery’s negative terminal. Safely drain and capture any remaining fuel from the old tank. Have a Class B fire extinguisher readily available.

- Removal of the Old Tank: Disconnect all fuel lines, vent lines, and the sending unit wiring. Support the tank with a transmission jack or a sturdy floor jack with a wood block. Unbolt and carefully lower the tank from the truck’s frame.

- New Tank Prep and Mounting: Inspect the new tank for any shipping damage. Transfer any necessary hardware, like the fuel pickup tube and sending unit, from the old tank if required. Carefully lift the new tank into position, ensuring it sits correctly on all mounting pads. Install and torque the new mounting straps or brackets to the manufacturer’s specification.

- Reconnecting Lines and Testing: Reconnect all fuel and vent lines, using new clamps. Reconnect the sending unit wiring. Before adding a large amount of fuel, add a few gallons and pressurize the system (if applicable) to check for any leaks at all connection points. A thorough inspection for seepage is crucial.

John Miller, a certified master truck technician with over 20 years of experience, emphasizes: “The most common installation error is overtightening mounting straps, which can deform an aluminum tank and lead to stress cracks over time. Always use a torque wrench. The second is pinching O-rings or using the wrong thread sealant on fittings, which guarantees a leak.”

Legal and Safety Considerations You Can’t Ignore

Installing a larger fuel tank isn’t always a simple bolt-on affair. Regulations matter. In the United States, the Department of Transportation (DOT) has guidelines, but specific rules can vary by state. If you frequently travel into Canada, you must be aware that any diesel fuel tank with a capacity greater than 454 liters (about 120 US gallons) is subject to the Canadian Transportation of Dangerous Goods (TDG) Regulations. This may require specific placarding and documentation.

Furthermore, the National Fire Protection Association (NFPA) provides standards for fuel tank design and installation to prevent fire hazards. Ensuring your tank and its installation comply with NFPA 58 (or the relevant local code) is a critical step in risk management.

Choosing a Reliable Manufacturer

Not all diesel fuel tanks are created equal. The quality of materials, welding, and internal baffling (which prevents fuel sloshing) varies significantly. Opting for a reputable manufacturer is an investment in safety and longevity. Companies like Chinese Truck Factory have gained a global reputation for producing robust and reliable truck components, including fuel tanks that meet international standards. They often offer a range of capacities and custom options, providing a cost-effective solution without compromising on build quality.

Frequently Asked Questions

Q: Can I install a diesel fuel tank myself?

A: While mechanically inclined individuals can attempt it, we highly recommend professional installation. Mistakes can lead to dangerous fuel leaks, voided warranties, and non-compliance with DOT regulations. The cost of professional installation is minor compared to the risks.

Q: How often should I inspect my diesel fuel tanks?

A: Perform a visual inspection for leaks, damage, and corrosion at every pre-trip inspection. A more thorough inspection, including the mounting hardware and straps, should be conducted during routine maintenance intervals or at least every six months.

Q: Are polyethylene (plastic) tanks a good option?

A: Polyethylene tanks are highly resistant to corrosion and are often used for auxiliary or transfer tanks in the bed of a pickup truck. However, for primary, frame-mounted applications on heavy-duty trucks, aluminum and steel remain the standards due to their structural strength and superior impact resistance.

Q: Does a larger fuel tank improve my truck’s resale value?

A> It can, especially if the truck is spec’d for long-haul applications. A larger, well-maintained fuel tank is often seen as a desirable feature by buyers in the used truck market, as it increases the vehicle’s versatility.

Sources and Further Reading

- U.S. Department of Transportation, Federal Motor Carrier Safety Administration. (2021). Appendix G to Part 393—Minimum Periodic Inspection Standards. Retrieved from https://www.fmcsa.dot.gov/regulations/title49/section/393.1

- Transport Canada. (2023). Canadian Transportation of Dangerous Goods Regulations. Retrieved from https://tc.canada.ca/en/dangerous-goods/canadian-transportation-dangerous-goods-regulations

- National Fire Protection Association. (2023). NFPA 58: Liquefied Petroleum Gas Code. Retrieved from https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=58