Tarp Switch for Dump Truck: Reliable Cover Control Solutions

Operating a dump truck efficiently requires reliable cover control solutions that stand up to demanding work conditions. The tarp switch for dump truck systems represents one of the most critical components in managing truck covers effectively, ensuring both safety and compliance during transport. Whether you’re hauling construction debris, agricultural products, or any other loose material, having a dependable tarp switch can mean the difference between a smooth operation and costly delays. This article explores the various aspects of dump truck tarp switches, from basic functionality to advanced features, helping you make informed decisions for your fleet.

Understanding Dump Truck Tarp Systems

Dump truck tarp systems are designed to securely cover loads during transportation, preventing material loss and ensuring road safety. The tarp switch serves as the control center for these systems, allowing operators to deploy or retract covers with minimal effort. Unlike manual tarping methods that require physical labor and pose safety risks, electric tarp switches provide precise control at the push of a button.

Modern tarp systems typically consist of several key components:

- Electric or hydraulic motor

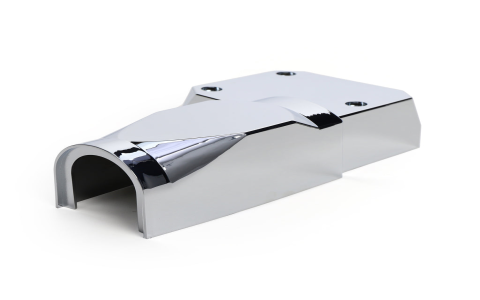

- Control switch assembly

- Roller mechanisms

- Support arms and frames

- Durable tarp material

The evolution of tarp technology has seen significant improvements in reliability and ease of use. Where early systems often suffered from mechanical failures and electrical issues, today’s advanced tarp switches incorporate weather-resistant materials and improved circuitry for longer service life.

Types of Tarp Switches Available

When selecting a tarp switch for your dump truck, understanding the different types available will help you choose the most appropriate system for your specific needs.

Momentary Contact Switches

These switches require continuous pressure to operate the tarp system, providing enhanced safety by immediately stopping movement when released. They’re particularly useful for precise positioning and preventing over-extension of the tarp mechanism.

Maintained Contact Switches

Maintained contact switches remain in position once activated, allowing the tarp system to complete its cycle without constant operator attention. These are ideal for applications where full deployment or retraction is typically required without intermediate stopping.

Remote Control Systems

Advanced tarp systems now offer wireless remote controls, allowing operators to manage cover functions from a safe distance. This technology significantly improves safety by keeping personnel away from potential hazards during tarp operation.

Key Features of Reliable Tarp Switches

Not all tarp switches are created equal. High-quality systems share several important characteristics that contribute to their reliability and longevity.

Durability stands as the most crucial factor. The switch must withstand vibration, moisture, temperature extremes, and exposure to dust and debris. Look for switches with IP67 or higher ratings, indicating superior protection against environmental factors.

Ergonomics plays another important role. Switches should be intuitively designed for easy operation, even when wearing work gloves. Proper labeling and tactile feedback help prevent operator error during critical operations.

Electrical compatibility ensures the switch integrates seamlessly with your truck’s existing electrical system. Quality switches feature robust connectors and proper circuit protection to prevent electrical issues that could lead to system failure.

Comparative Analysis: Popular Tarp Switch Systems

The following table compares three common types of tarp switches available in the market:

| Switch Type | Best Application | Durability Rating | Average Lifespan | Installation Complexity |

|---|---|---|---|---|

| Basic Rocker Switch | Light-duty applications | IP65 | 2-3 years | Low |

| Heavy-Duty Toggle | Standard dump trucks | IP67 | 4-5 years | Medium |

| Programmable Controller | Fleet operations | IP69K | 7+ years | High |

Installation and Maintenance Best Practices

Proper installation and maintenance significantly impact the performance and lifespan of your dump truck tarp switch. Following manufacturer guidelines precisely ensures optimal operation from day one.

During installation, pay close attention to:

- Correct wiring connections and proper grounding

- Secure mounting to minimize vibration damage

- Weatherproofing of electrical connections

- Adequate clearance from moving parts

Routine maintenance should include regular inspection of electrical connections, testing switch functionality, cleaning contact surfaces, and verifying weather seals remain intact. According to maintenance records from fleet operators, trucks receiving quarterly tarp system inspections experience 62% fewer switch failures compared to those with annual inspections alone.

Expert Insights on Tarp Switch Selection

We consulted with industry specialists to gather professional recommendations on selecting the right tarp switch for dump truck applications. Michael Reynolds, a certified equipment specialist with over 15 years of experience in commercial vehicle systems, emphasizes several key considerations.

“The operating environment should dictate your switch selection,” Reynolds explains. “For trucks working in corrosive environments like salt routes or chemical hauling, you need switches specifically designed to resist corrosion. The internal components must be properly sealed, and external materials should be stainless steel or high-quality polymers.”

Reynolds also highlights the importance of matching the switch to your specific tarp mechanism. “An undersized switch controlling a heavy-duty tarp system will fail prematurely. Always verify the electrical specifications, particularly the current rating, to ensure compatibility with your tarp motor.”

Troubleshooting Common Tarp Switch Issues

Even with quality components, occasional issues may arise. Understanding how to diagnose and address common problems can minimize downtime and repair costs.

One frequent issue involves intermittent operation, often caused by corroded connections or damaged wiring. Begin troubleshooting by inspecting all electrical connections for corrosion or looseness. Check wiring for signs of chafing or crushing, particularly where lines pass through metal surfaces or near moving components.

Another common problem is the tarp stopping mid-cycle, which might indicate an overload condition or failing motor. Modern systems often include thermal protection that automatically shuts down the motor when excessive current is detected. Allow the system to cool before attempting further operation, and investigate the cause of the overload.

Future Trends in Tarp Control Technology

The evolution of dump truck tarp systems continues with several emerging technologies poised to improve functionality and reliability. Smart control systems represent the next frontier, incorporating sensors and connectivity features that provide real-time monitoring and diagnostics.

Integrated sensor technology can detect potential issues before they cause failures. These systems monitor parameters like motor current, cycle times, and resistance, alerting operators to developing problems. Some advanced systems can even predict maintenance needs based on usage patterns and performance data.

Automation features are also becoming more sophisticated. New systems can automatically deploy covers when the truck reaches a predetermined speed or detect when the dump box is lowered and retract the tarp accordingly. These innovations reduce operator workload while ensuring consistent cover operation.

Frequently Asked Questions

What is the average lifespan of a quality tarp switch?

A well-maintained tarp switch typically lasts between 5-7 years under normal operating conditions. Higher-quality switches with better sealing and robust components can exceed this range, while cheaper alternatives may require replacement in as little as 2-3 years.

Can I install a tarp switch myself, or should I seek professional installation?

While basic mechanical skills may suffice for simple switch replacements, complex installations involving wiring modifications or system integration should be handled by qualified technicians. Improper installation can lead to electrical issues, void warranties, and potentially create safety hazards.

How do I know if my tarp switch needs replacement?

Common signs of a failing tarp switch include intermittent operation, the need for repeated pressing to activate, physical damage to the switch housing, or visible corrosion on electrical contacts. Unusual sounds from the tarp mechanism when operating the switch may also indicate electrical issues.

Are there waterproof tarp switches available?

Yes, many manufacturers offer waterproof tarp switches with IP67 or higher ratings. These switches feature special sealing around buttons and connections to prevent water ingress, making them ideal for dump trucks operating in wet conditions or requiring frequent washdowns.

What should I consider when upgrading my tarp system?

When upgrading your tarp system, consider compatibility with existing components, the electrical requirements of the new switch, physical mounting dimensions, and whether additional features like remote operation would benefit your specific application. Consulting with a specialist can help identify the best upgrade path for your needs.

Conclusion

Selecting the right tarp switch for your dump truck involves careful consideration of your specific operational requirements, environmental conditions, and budget constraints. By understanding the different types of switches available, their key features, and proper maintenance practices, you can ensure reliable cover control that enhances both safety and efficiency. As technology continues to advance, we can expect even more sophisticated tarp control solutions to emerge, further simplifying this critical aspect of dump truck operation.

For those considering comprehensive upgrades to their truck systems, Chinese Truck Factory offers a range of compatible components and expert guidance to help optimize your vehicle’s performance.