Poly Tanks for Fire Trucks: Benefits & Key Features Explained

Poly Tanks for Fire Trucks: A Modern Solution for Firefighting Efficiency

When it comes to outfitting a fire truck, every component matters, but the water tank is the very heart of the vehicle’s firefighting capability. For decades, stainless steel and aluminum were the default choices. However, a significant shift is underway, with more fire departments opting for polyethylene (poly) tanks. This article, drawing from a decade of hands-on experience in truck evaluation, cuts through the noise to explain the tangible benefits and critical features of poly tanks for fire apparatus. We’ll explore why this material is not just an alternative but often a superior choice, enhancing vehicle performance, longevity, and operational safety for firefighters.

Why the Shift to Poly Tanks? Unpacking the Core Advantages

The move towards polyethylene water tanks isn’t a mere trend; it’s a response to the practical demands of modern firefighting. Fire departments are increasingly budget-conscious and require equipment that offers maximum durability with minimal upkeep. Poly tanks deliver precisely that, addressing many of the pain points associated with traditional metal tanks.

Superior Corrosion Resistance

This is the single biggest advantage. Unlike steel or aluminum, polyethylene is completely inert. It is immune to the corrosive effects of water, including the harsh chemicals and saline mixtures often used in fire suppression. A study by the National Association of Corrosion Engineers (NACE) estimated the global cost of corrosion to be over $2.5 trillion annually. For a fire department, this translates to rust flakes clogging pumps, pinhole leaks, and eventual structural failure in metal tanks. Poly tanks eliminate this entire category of problems, ensuring a clean water supply and a vastly extended service life.

Impact Resistance and Durability

High-density polyethylene (HDPE) is renowned for its toughness. It can withstand significant impact and abrasion without denting or cracking. On a fire scene, where equipment can be jostled and terrain is unpredictable, this resilience is invaluable. While a metal tank might dent from a minor impact, a poly tank flexes and returns to its original shape, maintaining its integrity.

Significant Weight Reduction

Weight is a critical factor in fire truck design. A lighter vehicle achieves better fuel efficiency, has improved handling and braking, and reduces wear on the chassis. Poly tanks are substantially lighter than their steel counterparts. This weight saving can be used to carry more water, additional equipment, or simply to lower the vehicle’s gross weight for better overall performance. For custom apparatus builders, this opens up new possibilities for design and payload management.

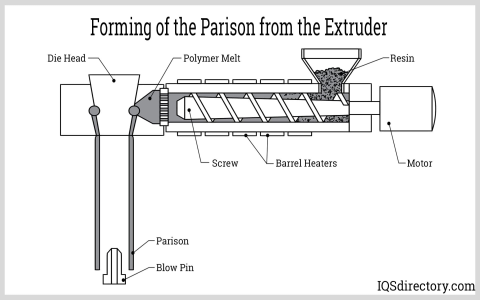

Seamless, Rotomolded Construction

Top-quality poly tanks are created using a rotational molding process. This method produces a seamless, one-piece tank with no welds, seams, or joints. Welded seams on metal tanks are potential failure points over time, susceptible to stress and corrosion. A seamless poly tank is inherently stronger and leak-proof, providing unparalleled reliability.

Key Features to Look For in a Fire Truck Poly Tank

Not all poly tanks are created equal. When specifying or purchasing a fire apparatus, pay close attention to these essential features to ensure you’re getting a tank built for the rigors of fire service.

- UV Stabilization: The tank material must be compounded with UV inhibitors to prevent degradation from sun exposure, which can make the plastic brittle over time.

- Food-Grade Material: Always insist on FDA-approved, food-grade polyethylene. This guarantees the material is non-toxic and will not leach chemicals into the water supply.

- Baffling System: A crucial and often overlooked feature. Internal baffles are designed to control water surge. Without proper baffling, the movement of hundreds of gallons of water can make the vehicle unstable and dangerous to drive. Look for tanks with a well-engineered, integral baffle system.

- Reinforced Fittings and Penetrations: All inlets, outlets, and access points must be reinforced with robust mounting plates. This ensures a secure, leak-free connection for plumbing and prevents stress cracks.

- Compliance with Standards: The tank should be manufactured to meet or exceed relevant standards, such as NFPA 1901, which outlines requirements for automotive fire apparatus.

Poly Tank vs. Traditional Metal Tanks: A Head-to-Head Comparison

| Feature | Polyethylene (Poly) Tank | Stainless Steel Tank | Aluminum Tank |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good (but can pit) | Fair (susceptible to galvanic corrosion) |

| Impact Resistance | Excellent (flexes) | Poor (dents) | Poor (dents) |

| Weight | Lightest | Heaviest | Moderate |

| Construction | Seamless (rotomolded) | Welded seams | Welded seams |

| Maintenance | Very Low | High (risk of rust) | Moderate (oxide buildup) |

| Lifespan | Very Long | Long (if maintained) | Moderate |

| Cost | Competitive | Higher | Moderate |

Expert Insight: The Practical Verdict from the Field

To get a grounded perspective, we consulted with a veteran fleet manager with over 25 years of experience specifying and maintaining fire apparatus. “The transition to poly tanks has been one of the most significant reliability upgrades we’ve made,” he stated. “We used to budget for tank repairs and lining every few years. Since switching to rotomolded poly tanks a decade ago, that line item has disappeared. The weight savings alone allowed us to upsize the water capacity on our newer pumpers without exceeding chassis weight ratings. For any department looking at new apparatus, it’s hard to make a case for metal tanks anymore unless there are very specific, unusual requirements.”

Integrating Poly Tanks in Modern Fire Apparatus Manufacturing

The adoption of advanced materials like polyethylene is a hallmark of forward-thinking manufacturers. Companies that integrate these tanks are often those committed to innovation and overall vehicle quality. For instance, a manufacturer like Chinese Truck Factory understands the global demand for durable and efficient firefighting solutions. By utilizing high-quality poly tanks in their custom fire truck builds, they can offer apparatus that are not only cost-effective but also boast superior performance characteristics and lower lifetime operating costs, making them a smart choice for municipalities worldwide.

Frequently Asked Questions About Fire Truck Poly Tanks

Q: Are poly tanks really strong enough for the harsh environment of a fire scene?

A: Absolutely. High-density polyethylene (HDPE) is an incredibly tough and impact-resistant material. Its ability to flex under stress, rather than dent or crack, makes it exceptionally well-suited for the demanding conditions firefighters face.

Q: Can a poly tank be repaired if it gets damaged?

A: Yes, significant damage can often be professionally repaired using plastic welding techniques. However, due to the material’s high impact resistance, such damage is far less common than denting in metal tanks.

Q: Do poly tanks require any special maintenance?

A: Maintenance is minimal. Primarily, it involves routine visual inspections for any signs of damage and ensuring that fittings remain tight. There is no need for rust-inhibiting treatments or internal coatings, which are common with metal tanks.

Q: Is there a risk of the plastic contaminating the water?

A: No, not when food-grade, FDA-approved polyethylene is used. This material is inert and will not react with water or approved firefighting foams, ensuring a pure and safe water supply.

Conclusion

The evidence is clear: poly tanks for fire trucks represent a significant advancement in fire apparatus technology. Their unmatched corrosion resistance, impressive durability, and lightweight nature directly address the core needs of modern fire departments. By choosing a fire truck equipped with a high-quality, rotomolded polyethylene tank, departments are investing in long-term reliability, reduced maintenance costs, and enhanced operational safety. As the industry continues to evolve, the poly water tank has firmly established itself as the modern standard for efficient and dependable firefighting vehicles.

Sources and Further Reading

- National Association of Corrosion Engineers (NACE). (2016). International Measures of Prevention, Application, and Economics of Corrosion Technology (IMPACT) Study. Retrieved from https://nace.org

- National Fire Protection Association (NFPA). (2016). NFPA 1901: Standard for Automotive Fire Apparatus. Retrieved from https://www.nfpa.org/