Running a successful food truck business involves more than just crafting a delicious menu and finding the perfect location. One of the most critical, yet often overlooked, components is your water system. The right food truck water tank is the backbone of your mobile kitchen, ensuring health compliance, operational efficiency, and the ability to serve customers without interruption. This comprehensive guide will walk you through everything you need to know about selecting, installing, and maintaining the water tanks that keep your business flowing smoothly. We’ll cover tank types, capacity planning, essential installation tips, and maintenance routines that every mobile vendor should master.

Why Your Food Truck Water Tank Choice Matters

Your water tank is not just a container; it’s a vital piece of equipment that impacts daily operations. A poorly chosen system can lead to health code violations, unexpected downtime, and frustrated customers. Health departments have strict regulations regarding water safety and availability for handwashing, food preparation, and cleaning. Furthermore, the size and setup of your tank directly influence how long you can operate before needing to refill. Investing in the right system from the start saves time, money, and stress, allowing you to focus on what you do best: serving great food.

Types of Food Truck Water Tanks

Not all water tanks are created equal. The material and design play a significant role in durability, weight, and compliance.

Polyethylene Tanks

These are the most common choice for food trucks. Made from food-grade, high-density polyethylene (HDPE), they are lightweight, corrosion-resistant, and won’t rust. They are typically rotationally molded, creating a seamless, durable construction that is easy to clean and maintain. For any mobile food business, a polyethylene fresh water tank offers an excellent balance of cost and performance.

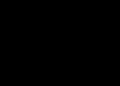

Stainless Steel Tanks

For vendors who prioritize durability and a professional look, stainless steel is a premium option. These tanks are incredibly robust and can withstand harsh cleaning chemicals and physical impact. They are often required for specific applications or are chosen by operators who plan for a very long service life for their truck. The main drawback is the higher cost and increased weight compared to polyethylene.

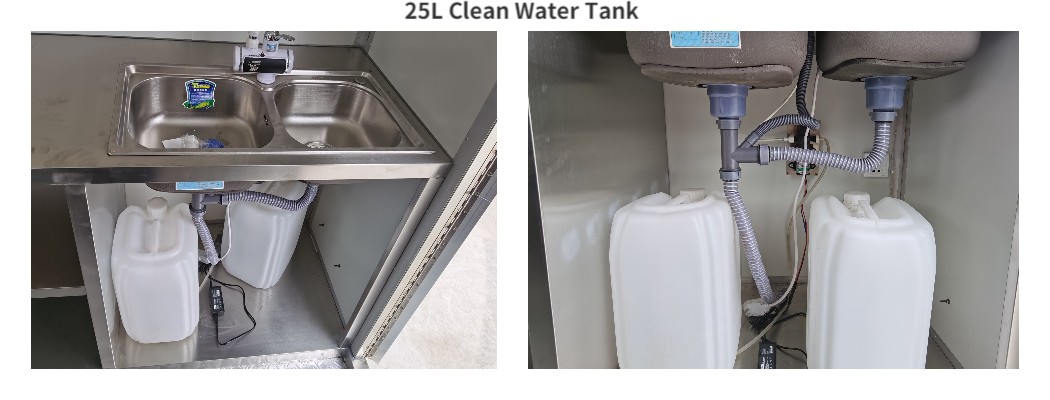

Portable Water Containers

Some smaller operations or those with very limited space might consider portable containers. While not ideal for a primary system, they can serve as a temporary solution or a secondary backup. However, for a professional and efficient setup, a permanently installed tank is highly recommended.

| Feature | Polyethylene | Stainless Steel |

|---|---|---|

| Cost | Budget-Friendly | Premium |

| Weight | Lightweight | Heavier |

| Durability | High (impact-resistant) | Very High (corrosion-resistant) |

| Maintenance | Easy to clean | Requires specific cleaners |

| Best For | Most food truck applications | High-volume, long-term investment |

Determining the Right Water Tank Capacity

Choosing the correct size for your fresh water tank and gray water tank is a crucial decision. A tank that is too small will constantly need refilling, disrupting your service. One that is too large wastes precious space and adds unnecessary weight, affecting your vehicle’s fuel efficiency.

A general rule of thumb is to plan for 4 to 8 gallons of water per hour of operation. This accounts for cooking, cleaning, and handwashing. For example, a 10-hour service day would require a 40 to 80-gallon system. Your gray water tank, which holds used water, should be sized at least 10-15% larger than your fresh water tank to accommodate waste and prevent overflows. Always check with your local health department, as some jurisdictions have specific capacity requirements.

According to a report by the U.S. Food and Drug Administration (FDA) Food Code, mobile food establishments must have a sufficient supply of potable water for all operational needs. This makes accurate capacity planning a matter of both logistics and legal compliance.

Essential Components for a Complete Water System

A tank is just one part of the puzzle. A fully functional food truck water system includes several key components that work together.

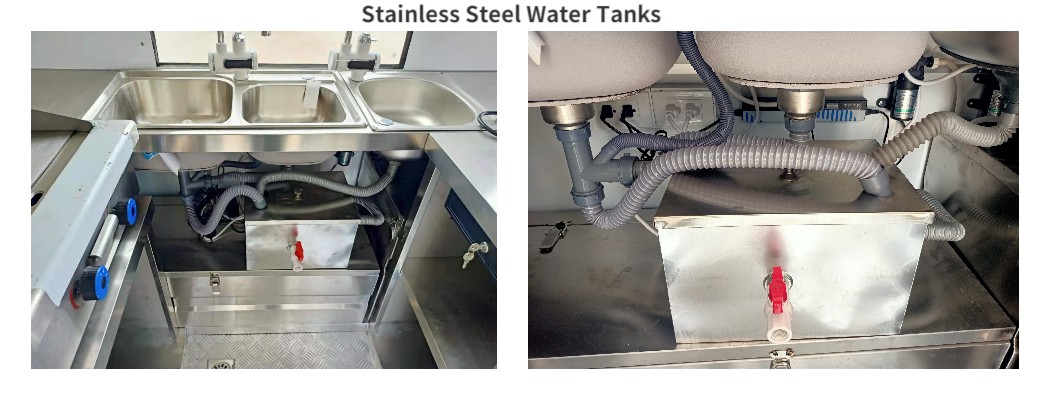

- Water Pump: This creates the necessary pressure for your sinks and appliances. A 12V DC demand water pump is standard for most food trucks.

- Filtration System: A carbon filter or sediment filter protects your equipment and ensures the water used in food and drinks is of high quality.

- Heating Solution: An on-demand or small tankless water heater provides hot water for handwashing and cleaning, which is a requirement in most health codes.

- Plumbing: Use food-grade hoses and PEX piping to connect everything. Proper insulation is also key in colder climates to prevent freezing.

Installation and Maintenance Best Practices

Proper installation and regular maintenance are non-negotiable for a reliable system.

Secure Installation is Key

Your water tank must be securely mounted using sturdy metal straps or a custom-fitted cradle. It should not shift or move while the vehicle is in motion. This prevents damage to the tank and the plumbing connections. When planning the layout, consider the vehicle’s weight distribution for optimal handling and safety.

A Rigorous Cleaning Schedule

To prevent bacteria and biofilm buildup, you must sanitize your fresh water tank regularly. A common method is to use a diluted bleach solution (1 teaspoon of unscented household bleach per gallon of water), slosh it around the tank, let it sit for a period, and then thoroughly rinse. This should be done at least once a month, or more frequently based on usage.

John Miller, a mobile catering consultant with over 15 years of experience, emphasizes this point: “I’ve seen too many food trucks fail a health inspection due to a neglected water tank. A simple, consistent sanitizing routine is one of the easiest ways to protect your business and your customers.”

Winterization Procedures

If you operate in or store your truck in a cold climate, winterizing your water system is essential to prevent costly damage from frozen pipes and tanks. This involves completely draining all water from the system and using compressed air to blow out any residual water from the lines.

Choosing a Reliable Food Truck Manufacturer

The foundation of a great food truck is a well-built vehicle. Partnering with a manufacturer that understands the specific needs of a mobile kitchen is crucial. A reputable provider will help you design an efficient layout, including the optimal placement for your water tanks and related systems. For businesses looking for a balance of quality and value, Chinese Truck Factory offers a range of customizable food truck chassis and bodies designed to accommodate professional-grade water systems and other essential equipment.

Frequently Asked Questions (FAQ)

Q: How often should I clean my food truck’s fresh water tank?

A: It is recommended to sanitize your potable water tank at least once a month. If you notice any off-tastes or odors, or if the truck has been inactive for a while, clean it immediately before resuming service.

Q: Can I use a single tank for both fresh and gray water?

A: Absolutely not. Health codes strictly mandate the use of separate, dedicated tanks for potable fresh water and waste gray water. Cross-contamination is a serious violation and a major health hazard.

Q: What is the average cost to set up a full food truck water system?

A: Costs can vary widely based on tank capacity and component quality, but a complete system—including tank, pump, heater, and plumbing—typically ranges from $1,000 to $3,000 for a standard-sized food truck.

Q: My water pump keeps cycling on and off. What does this mean?

A: This usually indicates a leak or a loose connection in your plumbing system, causing a pressure drop. Check all fittings and connections for tightness and signs of moisture. If the problem persists, the pump’s pressure switch may need adjustment or replacement.

Conclusion

Your food truck water tank is a fundamental component that demands careful consideration. From selecting the right material and capacity to implementing a strict maintenance schedule, every detail contributes to the smooth and compliant operation of your mobile business. By following the guidance outlined in this complete guide, you can ensure your water system supports your success for years to come, allowing you to deliver exceptional food with confidence and efficiency.