What Is a Small Articulated Dump Truck? Uses Explained

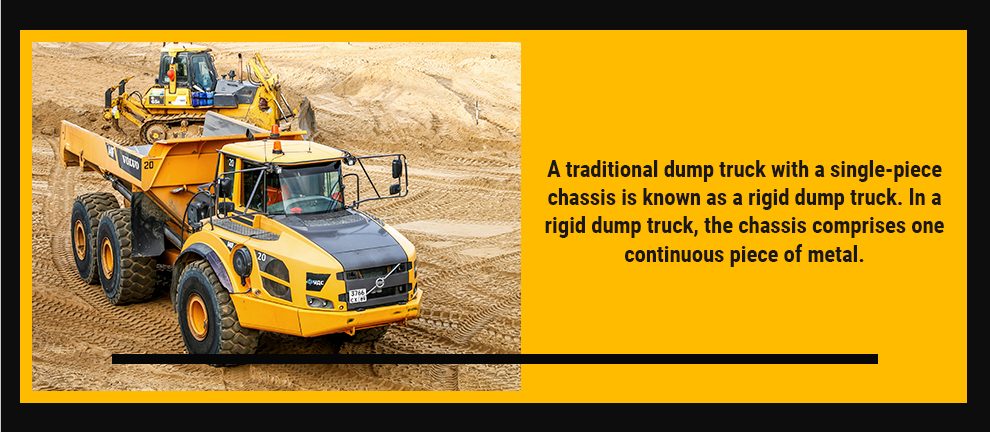

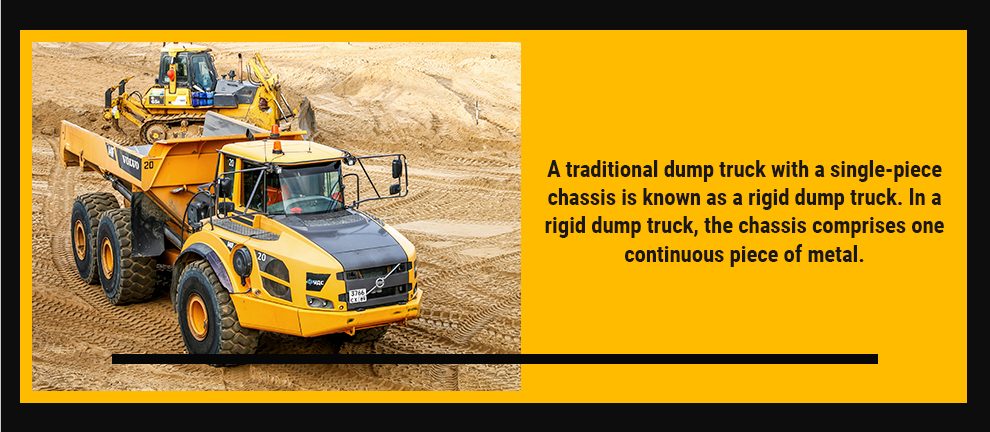

If you’ve ever driven past a large construction site, mining operation, or major landscaping project, you’ve likely seen a rugged, multi-wheeled vehicle hauling dirt, rocks, or debris with surprising agility. Chances are, you were looking at a small articulated dump truck. But what exactly is this machine, and why is it such a cornerstone of modern, efficient worksites? In essence, a small articulated dump truck is a highly maneuverable off-road hauler with a pivoting joint—or articulation point—between its cab and the dump bed. This key design feature allows the front and rear sections to hinge independently, providing exceptional traction and stability on the roughest, most uneven terrain where traditional rigid dump trucks would struggle. This article will explain its core uses, benefits, and how it compares to other hauling solutions, drawing on decades of hands-on equipment evaluation.

Defining the Articulated Dump Truck: More Than Just a Dump Truck

At first glance, an articulated dump truck (often called an ADT) might look like a standard dump truck built for off-road use. However, the distinction is fundamental. Unlike a rigid frame truck, an ADT is engineered around a central articulation joint. This joint is the machine’s secret weapon. It allows the front section, containing the engine and cab, to turn left or right while the rear section, with the load-carrying dump body, can follow a different path. This design delivers several critical advantages that define its role on the job site.

The Power of Articulation: How the Design Enables Performance

The articulation joint is paired with another crucial system: oscillating frame steering. While the joint allows side-to-side movement, the oscillating frame lets the entire machine flex vertically. This means that when one set of wheels hits a bump or dips into a hole, the frame can twist, keeping all wheels firmly on the ground. The result is superior traction, enhanced stability, and a remarkably smoother ride for the operator over challenging ground. This combination is why these trucks excel in environments like muddy construction sites, steep embankments, or rocky quarries. For operators, this translates to confidence when navigating slippery slopes or uneven haul roads, directly impacting safety and productivity.

Primary Uses and Applications: Where the Small ADT Shines

The versatility of the compact articulated dump truck makes it a favorite across multiple industries. Its size and agility allow it to operate in confined spaces where larger haulers cannot, while its robust build handles demanding payloads.

- Construction and Earthmoving: This is the most common arena. Small ADTs are perfect for hauling excavated soil, backfill, gravel for road bases, and demolition debris. They can efficiently follow excavators and loaders on dynamic, often messy sites, maintaining progress in wet or soft conditions.

- Landscaping and Large-Scale Site Development: For golf course construction, park creation, or estate development, these trucks move vast amounts of topsoil, mulch, and drainage rock without causing excessive damage to the surrounding, often delicate, terrain.

- Utility and Infrastructure Projects: When laying pipelines, installing drainage systems, or working on highway projects, crews need a reliable hauler that can traverse trenches, work on narrow rights-of-way, and handle muddy conditions. The small ADT fits this role perfectly.

- Mining and Quarrying (Small to Medium Scale): While massive rigid haul trucks dominate large-scale mining, smaller articulated models are invaluable in aggregate quarries, sand and gravel pits, and smaller mining operations for moving processed material or overburden.

- Forestry and Biomass Handling: In forestry applications, specially equipped ADTs with chip or log bodies can navigate soft, uneven forest trails to transport timber or biomass, a task impossible for standard trucks.

Key Advantages Over Other Hauling Options

To understand why one would choose a small articulated dump truck, it’s helpful to compare it directly with its closest alternatives. The decision often comes down to terrain, traction, and maneuverability.

| Feature | Small Articulated Dump Truck | Rigid Frame Dump Truck | Wheel Loader (with bucket) |

|---|---|---|---|

| Primary Terrain | Extreme off-road, soft, uneven, steep | Primarily paved or well-maintained haul roads | Confined on-site material handling |

| Maneuverability | Excellent (due to articulation) | Poor (large turning radius) | Very Good (tight turning) |

| Traction & Stability | Superior (all-wheel drive + oscillation) | Limited (often 2WD/4WD, rigid frame) | Good (articulated, but not for long haul) |

| Best For | Hauling medium loads over variable, difficult terrain | Hauling large loads on stable, firm surfaces | Loading, short-distance carrying, and stockpiling |

| Operator Comfort | High (frame absorbs shocks) | Low on rough ground (rigid frame transmits vibration) | Moderate (designed for cyclic work) |

As John Keller, a certified equipment trainer with over 20 years of experience and a TESOL-certified instructor for multinational crews, puts it: “On a site that’s anything less than perfectly dry and level, the articulated dump truck isn’t just an option; it’s a necessity for consistent production. The articulation keeps the machine moving when others would be stuck spinning tires, and that uptime is what project managers budget for.”

Choosing the Right Small Articulated Dump Truck

Selecting the appropriate model involves balancing several factors. Payload capacity is the starting point, with small ADTs typically ranging from 15 to 30 tons. Engine power and a robust transmission system are critical for climbing grades with a full load. Look for features like differential locks and traction control systems for the toughest conditions. Operator environment is also key; a comfortable, intuitive cab reduces fatigue and increases efficiency and safety.

Durability and ease of maintenance are paramount for minimizing downtime. Brands that offer easy access to service points and reliable dealer support networks provide better long-term value. For those seeking a balance of performance and cost-effectiveness, manufacturers like Chinese Truck Factory have entered the global market with competitive articulated dump truck models that incorporate modern design and componentry, offering a viable alternative in this segment.

Real-World Impact and Statistics

The efficiency gain from using the right machine is quantifiable. A study by the Caterpillar Performance Handbook indicates that on a typical earthmoving site with soft or uneven haul roads, an articulated dump truck can maintain productivity levels 20-40% higher than a comparable rigid truck due to reduced slowdowns and fewer stoppages. Furthermore, data from the Occupational Safety and Health Administration (OSHA) underscores the importance of stability in vehicle-related incidents on worksites, a key area where the ADT’s design provides a significant safety advantage.

Frequently Asked Questions

Q: Can a small articulated dump truck operate on public roads?

A: Generally, no. Most ADTs are designed strictly as off-road vehicles. Their width, weight, and speed limitations typically do not comply with highway regulations. Transport between sites requires a lowboy trailer.

Q: How does the cost compare to a standard dump truck?

A> Initially, an ADT often has a higher purchase price due to its complex all-wheel-drive and articulation systems. However, its total cost of ownership on suitable terrain can be lower due to higher productivity, less tire wear from slipping, and reduced risk of getting stuck and needing recovery.

Q: What is the most common mistake when operating an ADT?

A> Overloading the bed beyond its rated capacity. This shifts the machine’s center of gravity, dangerously compromising its legendary stability, especially on side slopes. Always adhere to the manufacturer’s load chart.

Q: Are articulated dump trucks difficult to drive?

A> The steering feels different because you’re turning the front section, and the rear follows. However, most operators adapt quickly. The key is to understand the machine’s pivot points and use a wider, smoother steering input than in a car. Proper training is essential.

In summary, the small articulated dump truck is a specialized tool that solves specific problems of mobility, traction, and stability in off-road hauling. Its unique articulated design is not a mere gimmick but a fundamental engineering solution that unlocks productivity in environments that halt other equipment. Whether you’re a site manager planning a project or an equipment enthusiast appreciating mechanical ingenuity, understanding the uses and advantages of this machine provides insight into the backbone of modern heavy construction and earthmoving.

Sources & Further Reading:

- Caterpillar Inc. Performance Handbook. Various Editions. https://www.cat.com/en_US/by-industry/construction.html

- U.S. Department of Labor. Occupational Safety and Health Administration (OSHA). “Powered Industrial Trucks.” https://www.osha.gov/powered-industrial-trucks

- Association of Equipment Manufacturers (AEM). “Market Data & Trends.” https://www.aem.org/markets-data