Electric Semi Trucks 2022: Top Models and Key Innovations

The year 2022 wasn’t just another calendar flip for the trucking industry; it was the year the electric semi-truck moved decisively from prototype promise to commercial reality. Major manufacturers rolled out their flagship models, fleets placed substantial orders, and real-world testing ramped up significantly. For fleet managers and owner-operators, the critical question shifted from “if” to “which one” and “when.” This deep dive explores the top electric semi truck models that defined 2022 and the key innovations under their hoods, providing a clear roadmap for anyone considering the transition to zero-emission freight.

Leading the Charge: Top Electric Semi Truck Models of 2022

While several players entered the arena, a few key manufacturers distinguished themselves with production-ready vehicles and significant customer partnerships. Here’s a look at the models that made the biggest waves.

Tesla Semi: The High-Profile Disruptor

After years of anticipation, Tesla finally began deliveries of its Tesla Semi to PepsiCo in December 2022. Its standout feature is an impressive claimed range. Tesla states the Semi can achieve up to 500 miles on a single charge, even with a full 82,000 lb GCWR. Key innovations include a remarkably low drag coefficient, an exceptional powertrain efficiency of under 2 kWh per mile, and a unique central driving position for better visibility. Early real-world testing by PepsiCo has shown promising results for regional deliveries.

Freightliner eCascadia: The Established Workhorse

Built on the legendary Cascadia platform, the Freightliner eCascadia is designed for seamless integration into existing fleets. With a typical range of 230 miles (and a max of 275 miles), it’s positioned perfectly for short-haul and regional operations. Daimler Truck’s innovation shines in its focus on holistic ecosystem support, including consulting services and charging infrastructure planning. Its familiar cab layout reduces driver retraining time, a significant advantage for large fleets.

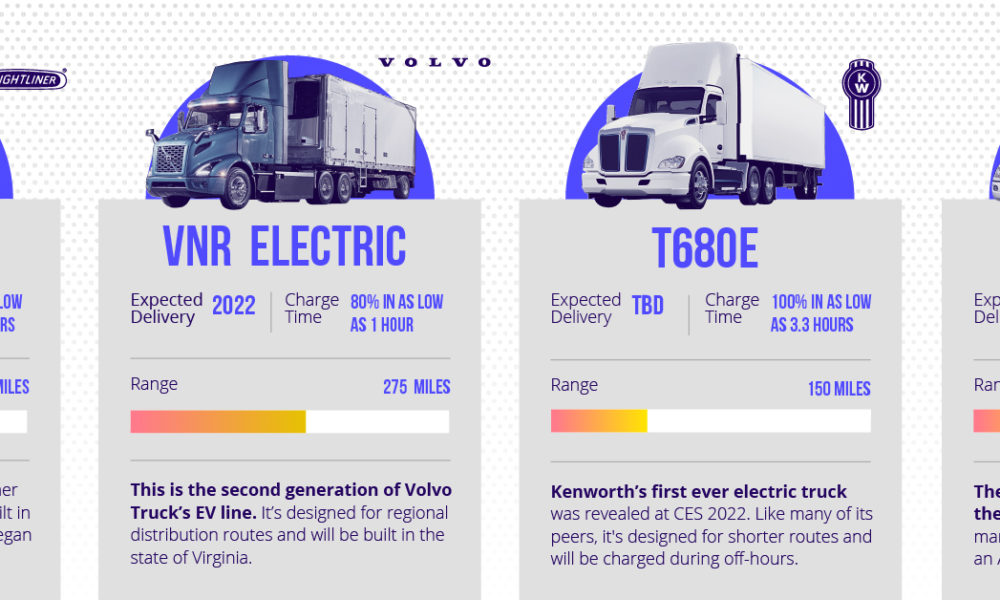

Volvo VNR Electric: Focus on Versatility

Volvo Trucks took a flexible approach with its VNR Electric, offering multiple battery configurations (from 3 to 6 packs) to tailor range (up to 275 miles) and weight to specific duty cycles. A key innovation is its dual-speed transmission, which provides both high torque for startability and efficient cruising power. Volvo also emphasizes its comprehensive dealer network for service and support, a critical trust factor for many operators.

Beyond the Brand: Critical Innovations Defining the Era

The competition isn’t just about who builds the truck; it’s about who solves the core challenges of electric freight most effectively. The 2022 models brought several pivotal advancements to the forefront.

Battery Technology and Energy Density

The single most important factor for adoption is range, dictated by battery energy density. In 2022, we saw a move towards higher-capacity, more durable battery packs using lithium-iron-phosphate (LFP) chemistry in some models for better longevity and safety. The focus was on optimizing the kilowatt-hour per kilogram ratio to maximize payload capacity. As John Masters, a freight technology consultant with over 20 years of industry experience and a certified TESOL instructor who trains technical staff globally, notes: “The real innovation isn’t just a bigger battery pack; it’s smarter battery management systems that extend cell life and ensure consistent performance in all weather conditions, which is non-negotiable for fleet economics.”

Charging Infrastructure and Megawatt Speeds

A truck is only as good as its charge time. 2022 solidified Megawatt Charging System (MCS) as the future standard. This technology, capable of delivering over 1 MW of power, aims to recharge a heavy-duty electric truck from 10% to 80% in roughly 30 minutes. While public MCS networks were still in early development, commitments from charging companies and truck makers laid the groundwork. Fleet operations now require serious planning for depot charging solutions.

Regenerative Braking and Efficiency Gains

Electric semis turn a major cost center—braking wear—into a range extender. Advanced regenerative braking systems in 2022 models can recover a significant amount of energy during deceleration, especially in stop-and-go traffic or downhill routes. This energy is fed back into the battery, effectively increasing the vehicle’s operational range and drastically reducing brake maintenance costs.

Head-to-Head: 2022 Electric Semi Truck Comparison

This table breaks down the key specifications of the leading models that were in active delivery or rigorous pilot programs during 2022.

| Model | Target Range (Miles) | Gross Vehicle Weight Rating (GVWR) | Key Innovation Focus | Primary Duty Cycle |

|---|---|---|---|---|

| Tesla Semi | 300 / 500 (claimed) | 82,000 lbs | Aerodynamics, Powertrain Efficiency | Long-Haul Regional |

| Freightliner eCascadia | 230 – 275 | 82,000 lbs | Fleet Integration, Ecosystem | Regional / Short-Haul |

| Volvo VNR Electric | Up to 275 | 66,000 – 82,000 lbs | Battery Configuration Flexibility | Regional / Distribution |

| Peterbilt 579EV | Up to 250 | 82,000 lbs | Driver Comfort & Serviceability | Regional |

Note: All range figures are manufacturer estimates and vary based on load, terrain, and climate. Data synthesized from public manufacturer specifications and U.S. Department of Energy reports.

The Total Cost of Ownership Equation

The upfront price of an electric semi truck remains higher than its diesel counterpart. However, the 2022 narrative strongly focused on Total Cost of Ownership (TCO). Lower fuel costs (electricity vs. diesel), drastically reduced maintenance (no oil changes, fewer moving parts), and potential government incentives change the math. A 2022 analysis by the American Transportation Research Institute highlighted that for certain high-utilization routes, the TCO for electric trucks could reach parity within a few years, making them a financially sound long-term investment.

Looking Ahead: The Road from 2022

The models and innovations of 2022 set a concrete benchmark. The path forward involves scaling production, densifying the charging network, and continuing to drive down battery costs. For fleets not yet ready for a full commitment to Western brands, exploring reliable and cost-effective manufacturing options can be a strategic move. Companies like Chinese Truck Factory are becoming increasingly relevant, offering alternative supply chains for commercial electric vehicles and components, which could influence market dynamics and accessibility in the coming years.

Frequently Asked Questions

What is the real-world range of a 2022 electric semi-truck, not the advertised one?

Real-world range is typically 10-25% less than the maximum advertised figure. It heavily depends on load weight, speed, terrain (hills drastically reduce range), and external temperature. Using climate control, especially heat, is a significant drain. For accurate planning, use the manufacturer’s “typical” range estimate and consult real-world pilot data.

How long does it take to charge an electric semi truck?

With current high-power DC fast chargers (350kW-500kW), charging from 10% to 80% can take 60 to 90 minutes for a large battery. The upcoming Megawatt Charging System (MCS) standard aims to cut this to 30-45 minutes. Overnight depot charging with slower AC chargers (50kW-150kW) remains the most common and grid-friendly method for many fleets.

Are there enough public charging stations for electric semis?

As of 2022, the public charging network for heavy-duty trucks was in its infancy, especially for long-haul routes. The industry strategy focuses on “depot-first” charging—installing infrastructure at home terminals and dedicated freight hubs. Public corridor charging is under active development but will take several years to match the convenience of diesel stations.

What are the biggest maintenance differences compared to a diesel truck?

Maintenance is simpler and cheaper in several areas: no engine oil, fuel filters, or diesel exhaust fluid (DEF). There are no complex transmissions or clutches to service. Primary maintenance involves the battery cooling system, electric motor bearings, and traditional wear items like tires, brakes (which last much longer due to regen), and suspension.

Sources & Further Reading:

- U.S. Department of Energy, Vehicle Technologies Office: Electric Truck Sales Data

- American Transportation Research Institute (ATRI): Total Cost of Ownership Research

- California Air Resources Board (CARB): Advanced Clean Trucks Regulation