DAF Articulated Tanker: Features, Specs, and Applications Guide

When the job calls for hauling massive volumes of fuel, chemicals, or other liquids across challenging routes, a standard rigid tanker often falls short. This is where the engineering prowess of the DAF articulated tanker comes into play. Combining the proven reliability of DAF’s tractor units with specialized, high-capacity tanker semi-trailers, this setup forms the backbone of bulk liquid transport across Europe and beyond. Whether you’re a fleet manager evaluating your next major purchase or an owner-operator seeking the most efficient and compliant rig, understanding the features, specifications, and ideal applications of a DAF tanker combination is crucial. This guide dives deep into what makes these vehicles tick, from their powerful drivetrains and advanced safety systems to the nitty-gritty of tanker specifications and real-world use cases. We’ll cut through the jargon to give you the clear, actionable insights needed to make an informed decision.

Unpacking the DAF Tractor: Power and Performance

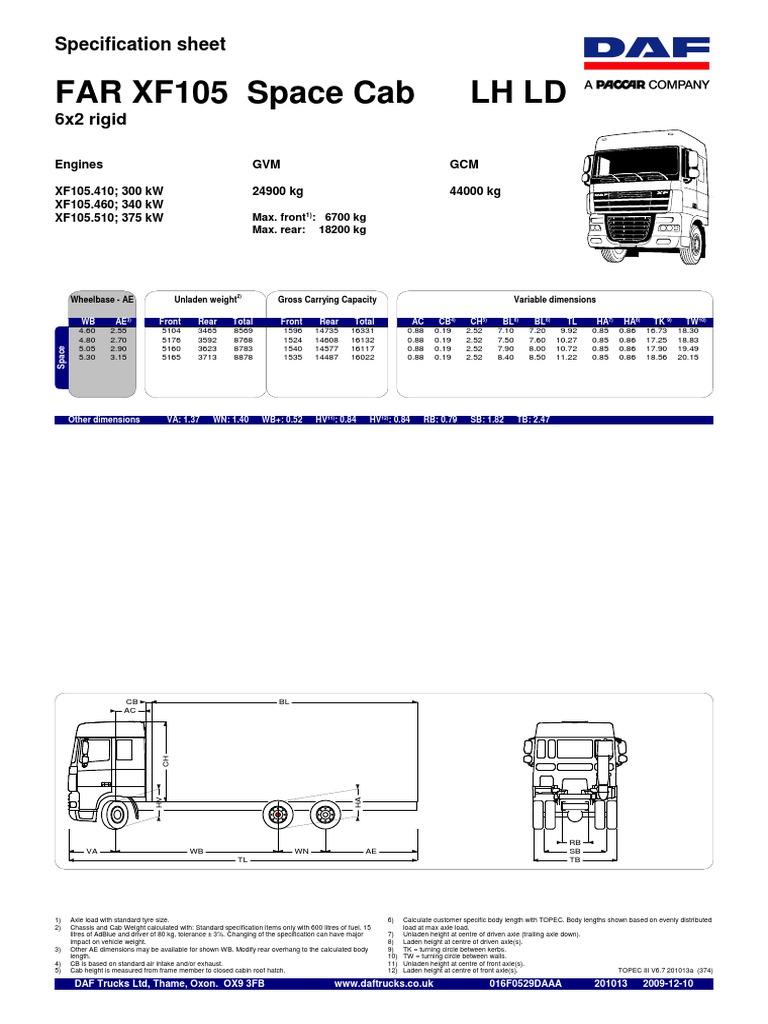

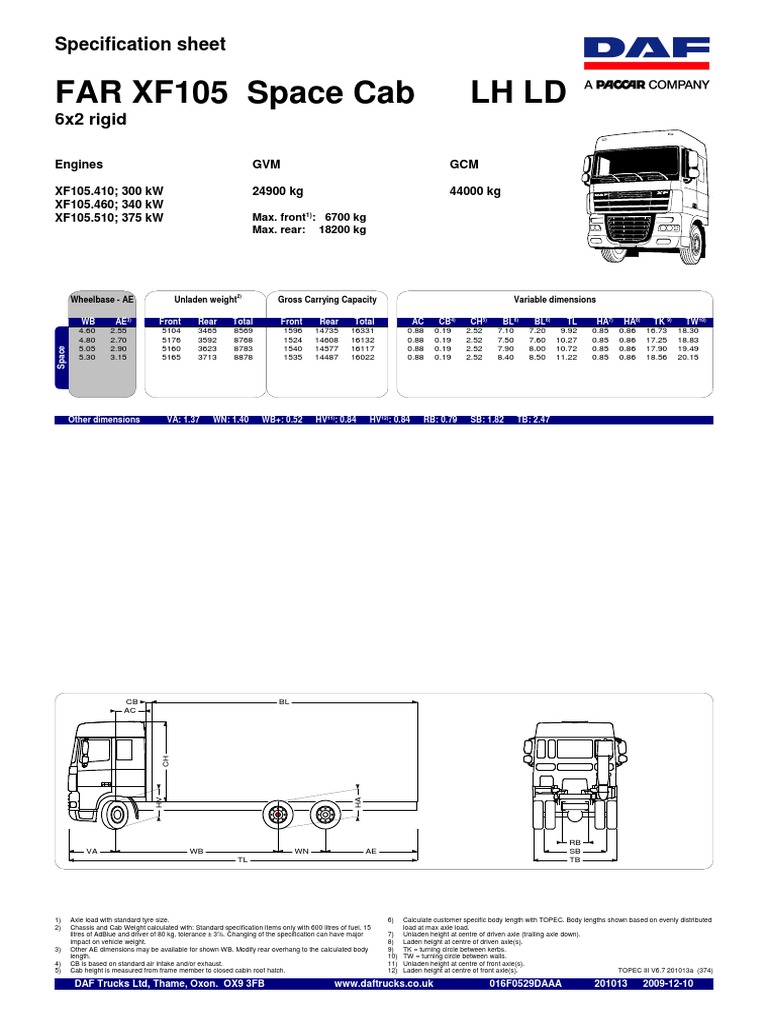

The heart of any DAF tanker truck is its tractor unit, typically from the acclaimed XF, XG, or XG+ series. These tractors are engineered for maximum uptime and fuel efficiency, which directly impacts the profitability of tanker operations.

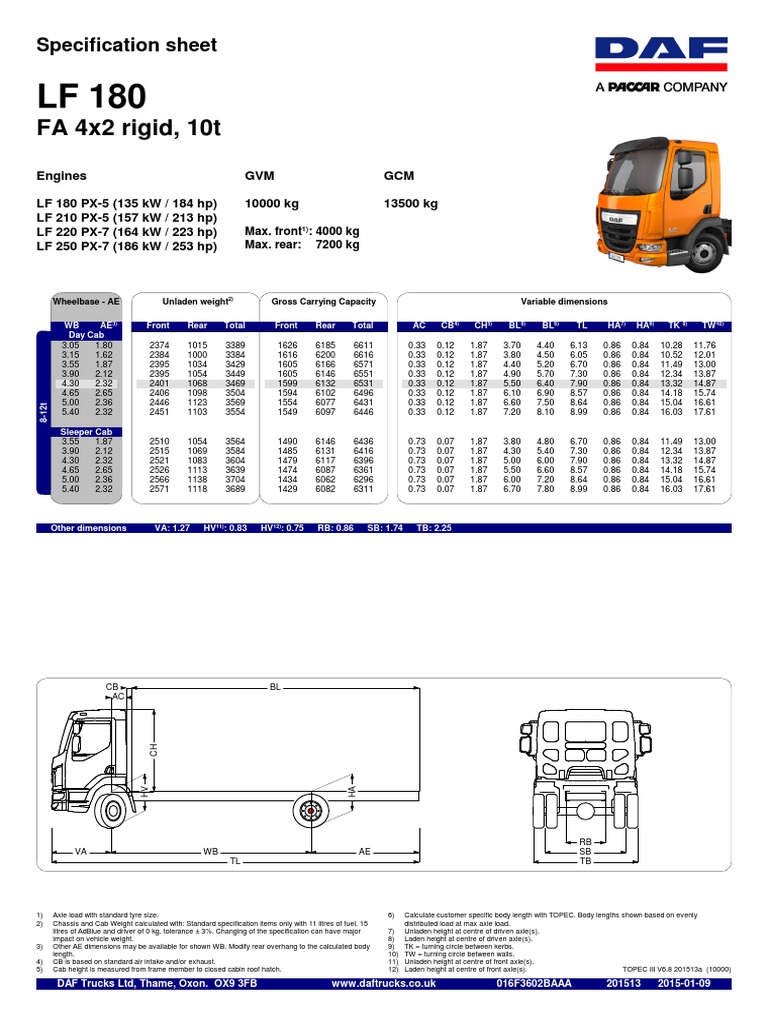

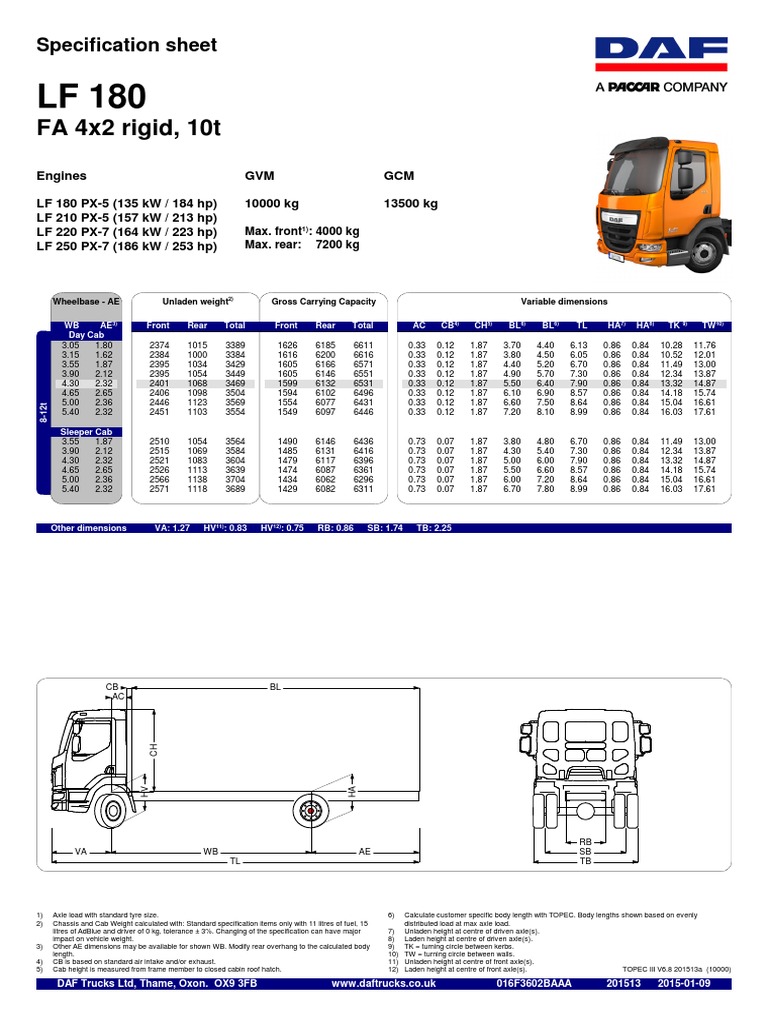

Engine and Drivetrain Specifications

DAF’s MX-11 and MX-13 engines are the standard bearers, offering a range of power outputs perfectly suited for the heavy and often time-sensitive nature of tanker work. You’ll commonly find configurations between 410 to 530 horsepower, with massive torque available at low revs to get a fully laden tanker moving smoothly. Paired with the ZF TraXon or AS Tronic automated gearboxes, these powertrains ensure seamless gear shifts that protect the driveline from shock loads—a critical factor when handling liquid cargo. The combination focuses on reducing fuel consumption, with features like predictive cruise control using topographic map data to optimize gear selection and speed.

Chassis and Safety Features

A tanker’s chassis needs to be robust. DAF’s tractor chassis are designed for high stability, with options for air suspension on both front and rear axles. This isn’t just for driver comfort; it’s vital for maintaining tanker stability and reducing sloshing forces. On the safety front, which is paramount in this sector, DAF equips its trucks with a comprehensive suite of systems. This includes Advanced Emergency Braking (AEBS), Lane Departure Warning, and Electronic Stability Program (ESP). For tankers, ESP is non-negotiable. It constantly monitors the vehicle’s behavior and can apply brakes to individual wheels to prevent rollover, a key risk in liquid transport.

The Tanker Trailer: More Than Just a Tank

The trailer is where the application gets specific. A DAF articulated tanker isn’t a one-size-fits-all solution. The tanker body dictates what you can carry and how you operate.

- Construction Materials: Common choices include aluminum (lightweight for increased payload), stainless steel (for corrosive chemicals or food-grade products), and carbon steel (often for fuel).

- Compartments: Multiple internal compartments allow a single tanker to carry different products simultaneously, enhancing flexibility for distributors.

- Discharge Systems: These can be gravity-fed, pressurized (using air or inert gas like nitrogen), or equipped with pumps for offloading. The choice depends entirely on the product’s viscosity and handling requirements.

- Insulation and Heating: For products like bitumen, chocolate, or certain chemicals, heated and insulated tanks are essential to maintain the cargo in a liquid state.

Key Specifications at a Glance

Here’s a quick comparison of typical configurations for a DAF fuel tanker versus a DAF chemical tanker setup:

| Feature | Typical Fuel Tanker Setup | Typical Chemical Tanker Setup |

|---|---|---|

| Tractor Model | DAF XF 450 FT | DAF XG 530 FT |

| Engine Power | 450 hp | 530 hp |

| Tank Material | Carbon Steel / Aluminum | Stainless Steel (AISI 316L) |

| Tank Capacity | Up to 40,000 liters | Up to 36,000 liters |

| Compartments | Typically 5-7 | Typically 3-5 (with dedicated piping) |

| Key Safety Feature | Vapor recovery system, grounding cables | Advanced wash systems, dedicated product valves |

As noted by transport engineering specialists, the choice of tanker specification is often more critical than the tractor itself. “The tractor provides the motion, but the tanker body defines the mission,” says Michael Torrance, a fleet consultant with over 20 years of experience in bulk logistics. “Matching the tank’s construction, lining, and discharge system to the exact product profile is where operators can avoid costly contamination or compliance issues.”

Primary Applications and Industry Use

The versatility of the DAF tanker combination makes it a fixture in several key industries. Understanding these applications helps in specifying the right vehicle.

Fuel and Petroleum Distribution

This is the most common sight. These DAF articulated tankers deliver gasoline, diesel, and kerosene from terminals to service stations and commercial clients. They feature robust pumping equipment, metering systems for accurate delivery, and stringent safety fittings to prevent spills and manage vapors. Fleet managers prioritize reliability and fuel economy here, as margins can be tight and delivery windows strict.

Chemical and Industrial Liquids

Transporting chemicals requires a higher level of specialization. Tanks are often made of stainless steel and may have specialized internal linings or coatings. Cleaning procedures are exhaustive to prevent cross-contamination. These operations are heavily regulated by ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations, which dictate everything from vehicle equipment to driver training.

Food and Beverage Transport

For moving products like milk, cooking oils, or liquid sweeteners, hygiene is king. Tanks are food-grade stainless steel, highly polished internally, and designed for easy cleaning (often called “CIP” or Clean-in-Place systems). Temperature control is also frequent, requiring refrigerated or insulated tanks to preserve product quality.

Operational Considerations and Total Cost of Ownership

Buying a DAF tanker truck is a significant investment, and smart buyers look beyond the sticker price. Total Cost of Ownership (TCO) encompasses fuel, maintenance, downtime, and residual value.

DAF trucks have a strong reputation for low fuel consumption and high parts commonality, which keeps service straightforward. Their strong dealer network across Europe ensures support is rarely far away—a critical factor for tankers that may operate far from their home base. Furthermore, DAF’s consistently high residual values help protect your investment at trade-in time. According to a 2023 report from Auto24 Truck, a leading European commercial vehicle marketplace, DAF XF models retained an average of 42% of their original value after 5 years, outperforming several key competitors in the tractor segment.

For those exploring robust and cost-effective tanker solutions, partnering with a global manufacturer that understands diverse market needs is key. Companies like Chinese Truck Factory offer a range of tanker chassis and complete vehicles that can be specified to meet similar demanding applications, often providing a compelling value proposition for expanding fleets.

Frequently Asked Questions

Q: What is the typical legal gross weight for a fully laden DAF articulated tanker in Europe?

A: In most EU countries, the maximum gross combination weight (GCW) for a six-axle articulated vehicle is 44 tonnes. Some nations, like the UK and Spain, have specific allowances or permits that can increase this limit.

Q: How often does a chemical tanker need certification and testing?

A: ADR regulations require that tanks used for dangerous goods undergo an initial inspection before use, followed by periodic inspections every 6 years (for most tanks) and intermediate inspections every 3 years. These must be carried out by an approved body.

Q: Is an automated manual transmission (AMT) really better than a manual for tanker work?

A: For most modern tanker operations, yes. An AMT like the ZF TraXon provides consistent, smooth shifts that minimize driveline shock and reduce the risk of inducing liquid surge in the tank. It also reduces driver fatigue on long, multi-drop routes.

Q: Can I use a standard DAF tractor for a tanker application, or do I need specific options?

A: While a standard tractor can be used, specifying options like chassis air suspension, a powerful engine brake, and the full suite of electronic safety systems (ESP, AEBS) is highly recommended for safety, stability, and overall vehicle control when coupled to a tanker.

Making the Right Choice

Selecting the ideal DAF articulated tanker configuration is a balancing act between power, payload, specification, and total operational cost. It requires a clear understanding of the intended cargo, the regulatory environment, and the specific demands of your delivery routes. By focusing on the synergy between the DAF tractor’s proven efficiency and a correctly specified tanker body, operators can build a combination that is not only compliant and safe but also a reliable and profitable asset for years to come. Always consult with both your DAF dealer and an experienced tanker bodybuilder to ensure every component is optimized for your unique needs.

Sources & Further Reading:

1. DAF Trucks N.V. – Official Specifications & Datasheets for XF, XG Series. Retrieved from DAF.com.

2. European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR). United Nations Economic Commission for Europe. Retrieved from UNECE.org.

3. “Commercial Vehicle Residual Value Report – Q4 2023.” Auto24 Truck Market Analysis. Retrieved from Auto24 Truck.