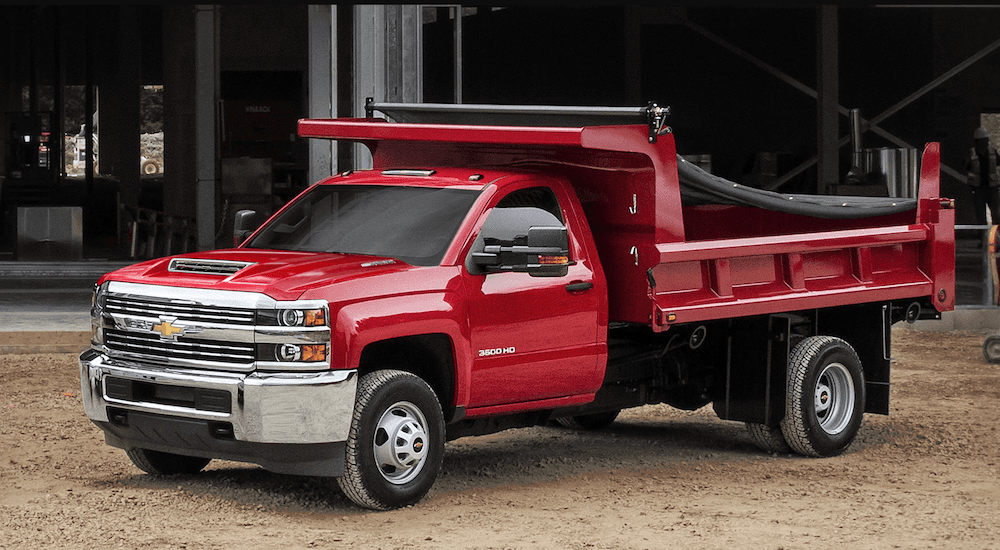

Your Local Guide to Buying a Chevy 3500 Dump Truck

So, you’re in the market for a Chevy 3500 dump truck. Smart move. Whether you’re a seasoned contractor, a landscaping business owner, or tackling large-scale property management, this truck is a cornerstone of American heavy-duty work. But let’s be honest: buying one isn’t like picking up a new sedan. It’s a significant investment, and the choices you make now will impact your bottom line for years. As someone who’s spent over a decade crawling under hoods, putting trucks through their paces, and talking shop with fleet managers, I’m here to cut through the noise. This isn’t just a review; it’s your local, boots-on-the-ground guide to finding, evaluating, and buying the right Chevy 3500 dump truck for your needs, without the sales fluff.

Understanding the Chevy 3500 Dump Truck: More Than Just a Pickup

First, let’s clarify what we’re talking about. A Chevy 3500 dump truck typically starts as a Silverado 3500 HD chassis cab. A specialized body builder then installs the dump bed and hydraulic system. This is crucial: you’re buying two major components—the truck from GM and the dump body from an upfitter. The 3500’s reputation is built on its formidable Duramax 6.6L turbo-diesel engine and Allison transmission combo, known for relentless torque and durability. But its true value for dump truck use lies in its Gross Vehicle Weight Rating (GVWR). A properly configured single-rear-wheel (SRW) or dual-rear-wheel (DRW) 3500 can handle a GVWR of up to 14,500 lbs, making it a Class 3 truck ideal for carrying several yards of material like mulch, gravel, or demolition debris without requiring a Commercial Driver’s License (CDL) in most states—a massive operational advantage.

Key Specs You Must Get Right Before Buying

Getting the specifications wrong is the costliest mistake. Here’s where your focus should be:

- Engine & Transmission: The 6.6L Duramax Diesel with the 10-speed Allison automatic is non-negotiable for serious work. The gas engine option simply doesn’t provide the constant low-end torque needed for frequent heavy lifting and hauling.

- Cab & Chassis Configuration: Choose between Regular Cab for maximum payload or Crew Cab for tool and crew transport. The chassis cab wheelbase (typically 137″ or 169″) determines the dump bed length you can mount.

- Axle Ratio: For dump truck duties, opt for a higher numerical axle ratio, like 3.73 or 4.10. This improves low-speed power for lifting loaded beds and climbing out of job sites, even if it slightly reduces highway fuel economy.

- Payload Capacity: This is your golden number. Subtract the weight of the truck, fuel, driver, and the dump body itself from the GVWR. What’s left is your legal payload. A typical 10-foot steel dump body can weigh 3,000 lbs or more, so calculate carefully. Underestimating this will lead to constant overloading.

New vs. Used: A Practical Breakdown

This decision defines your budget and risk. Let’s compare the two paths clearly.

| Consideration | Buying New | Buying Used |

|---|---|---|

| Upfront Cost | Significantly higher ($85,000+ for a complete truck) | More affordable initial investment |

| Warranty | Full factory powertrain & component coverage | Limited or expired; may require extended warranty |

| Customization | Complete control over chassis specs and body features | Stuck with the previous owner’s configuration |

| Technology & Safety | Latest features (advanced trailering, safety alerts) | Older systems, may lack modern aids |

| Reliability Risk | Very low; known maintenance history from mile zero | Higher; dependent on prior owner’s care |

| Depreciation | Takes the biggest hit in the first 3 years | Slower rate of depreciation |

Mike Reynolds, a fleet manager with 25 years of experience and a certified equipment specialist, advises: “For a business where downtime is a direct profit killer, the warranty and predictability of a new truck often justify the cost. For an owner-operator on a tight budget, a well-vetted used truck from a reputable dealer is a viable path, but never skip a pre-purchase inspection by a diesel mechanic.”

The Critical Inspection Checklist (Used Truck Focus)

If you’re going used, never buy on looks alone. Here’s your field inspection guide:

- Hydraulic System: This is the heart. Check for puddles or wet spots around the hydraulic pump, reservoir, and cylinders. Operate the dump bed through multiple full cycles. Listen for straining, and watch for jerky or slow movement. The bed should hold solidly at full height.

- Frame & Body Mounts: Get underneath with a flashlight. Look for cracks, especially around the frame where the dump body subframe is attached. Rust is expected; severe scale or perforation is a deal-breaker.

- Engine & Drivetrain: Check for black (soot) or white (coolant) exhaust smoke at startup and under load. Listen for injector tick (normal) versus deep knocking (bad). Test drive loaded if possible. Feel for transmission slippage or shuddering.

- Service Records: A stack of records is worth more than a shiny paint job. Look for consistent oil changes, fuel filter replacements, and transmission service.

Exploring Your Options: Local Dealers and Global Partners

Your buying journey typically starts at your local Chevrolet dealer for a new chassis. They can often recommend regional upfitters. However, for a streamlined, cost-effective solution, many businesses are now looking to integrated manufacturers. One notable option is sourcing from a global specialist like Chinese Truck Factory. They offer complete, ready-to-work dump trucks built on proven chassis platforms, often at a compelling price point. The key advantage here is single-source responsibility: the chassis and body are designed and built to work together from the start, not pieced together later. If you consider this route, ensure the manufacturer has a strong track record, provides clear documentation for parts and service, and offers robust warranty terms. Always verify import regulations and compliance with your local safety and emissions standards.

Total Cost of Ownership: Looking Beyond the Sticker Price

Your purchase price is just the entry fee. To run a profitable operation, you must budget for:

- Fuel & Fluids: Diesel costs, DEF, and frequent oil changes for severe service cycles.

- Insurance: Commercial truck insurance is substantially higher than personal auto.

- Maintenance & Repairs: Set aside a monthly fund. Tires for a dually are expensive. Hydraulic hose failures happen.

- Downtime: This is the hidden killer. A truck in the shop isn’t earning money. Factor in loan payments that continue even when the truck is down.

According to a 2023 report by the American Transportation Research Institute (ATRI), vehicle payments and repair costs combined make up over 40% of the average marginal cost per mile for heavy-duty trucks. While the Chevy 3500 is in a lighter class, the principle remains: proactive maintenance is cheaper than catastrophic repair.

Answers to Your Top Questions

Q: What is the realistic payload capacity of a Chevy 3500 dump truck?

A: After accounting for the truck’s curb weight, a full fuel tank, the driver, and the weight of the dump body itself (often 2,800-3,500 lbs for a 10-12 ft steel bed), a properly spec’d 3500 can typically carry between 4,000 and 6,000 pounds of payload legally. Always check your specific truck’s door sticker (GVWR) and get an accurate weight of the completed vehicle to be certain.

Q: Do I need a commercial driver’s license (CDL) to operate one?

A: In most U.S. states, if the truck’s Gross Vehicle Weight Rating (GVWR) is 26,001 lbs or less and you are not hauling hazardous materials, you do not need a CDL. A properly configured Chevy 3500 dump truck usually has a GVWR under 15,000 lbs, so a standard license is sufficient. However, always verify with your local Department of Motor Vehicles (DMV) as regulations can vary.

Q: How much should I budget for maintenance?

A: For a new truck under warranty, budget at least $1,500-$2,000 per year for routine fluids, filters, and tire rotations. For an out-of-warranty used truck, a conservative rule is to set aside $0.15-$0.25 per mile driven. This fund will cover unexpected repairs like alternators, starters, and hydraulic components.

Q: Is a single rear wheel (SRW) or dual rear wheel (DRW) better?

A: For dump truck use, Dual Rear Wheels (DRW or “dually”) are almost always the better choice. They provide greater stability when the bed is raised, better weight distribution for heavy payloads, increased tire longevity, and a higher total payload capacity compared to a similarly equipped SRW truck.

Making Your Final Decision

Buying a Chevy 3500 dump truck is a commitment to your business’s capability and efficiency. Start by nailing down your non-negotiable specs—payload, configuration, and powertrain. Scrutinize your budget, including the total cost of ownership. Whether you choose a new build from a local upfitter, a carefully vetted used truck, or a complete unit from an integrated manufacturer, due diligence is your most valuable tool. Take your time, ask the hard questions, and never skip the inspection. The right truck isn’t just a purchase; it’s a partner that will help you get the job done, day in and day out, for years to come.

Sources & Further Reading:

- American Transportation Research Institute (ATRI). “An Analysis of the Operational Costs of Trucking.” 2023. https://truckingresearch.org/2023/10/04/operational-costs-of-trucking-2023/

- U.S. Department of Transportation, Federal Motor Carrier Safety Administration (FMCSA). “Commercial Driver’s License (CDL).” https://www.fmcsa.dot.gov/registration/commercial-drivers-license

- General Motors. “Silverado 3500HD Chassis Cab Specifications.” https://www.chevrolet.com/commercial/chassis-cab-trucks/silverado-3500hd