Fuel Tanker Price Guide: 2024 Costs & Market Analysis

If you’re in the market for a fuel tanker truck, whether to expand your fleet or start a new hauling business, the first question is almost always about cost. The price tag isn’t a simple number; it’s a complex equation shaped by new regulations, shifting fuel demands, and global supply chains. This comprehensive guide breaks down the 2024 fuel tanker price landscape, providing a clear market analysis to help you make a smart investment. We’ll look at what drives costs, compare new and used options, and explore how operational choices impact your long-term budget.

Key Factors Influencing Fuel Tanker Prices in 2024

Understanding the sticker price requires looking under the hood at the components that add up. Several critical elements are shaping the market this year.

Material Costs and Regulatory Compliance

The steel and aluminum used in tank construction are subject to volatile global commodity prices. More significantly, stringent environmental and safety regulations are a major cost driver. Tanks must be built to exacting standards to prevent leaks and emissions. Compliance with these rules, while essential for safety and legality, adds considerable engineering and manufacturing expense to every unit.

Tank Capacity and Configuration

Size matters, but so does specialization. A standard 5,000-gallon aluminum tanker will have a very different price point than a 10,000-gallon stainless steel unit designed for corrosive chemicals. Additional features like multiple internal compartments, advanced vapor recovery systems, or specialized pumping equipment significantly increase the base price. Your specific hauling needs will directly dictate this core cost variable.

Chassis and Powertrain Specifications

The tank sits on a chassis, and this foundation is a huge part of the investment. A commercial truck chassis from a major brand like Freightliner or Volvo, equipped with a powerful diesel engine, robust transmission, and safety features like advanced braking systems, constitutes a large portion of the total cost. The choice between different engine horsepower ratings and axle configurations allows for customization but also affects the final price.

2024 Price Ranges: New vs. Used Fuel Tankers

To give you a practical financial picture, here’s a breakdown of what you can expect to invest in the current market. These are estimated ranges, and final prices depend on the exact specifications discussed earlier.

| Type | Capacity | Estimated Price Range | Key Considerations |

|---|---|---|---|

| New Fuel Tanker | 5,000 – 9,000 gallons | $180,000 – $350,000+ | Latest tech, full warranty, compliance-ready. Highest upfront cost. |

| Used Fuel Tanker (3-5 yrs old) | 5,000 – 9,000 gallons | $90,000 – $180,000 | Good value, some life remaining. Requires thorough inspection for corrosion and compliance. |

| Used Fuel Tanker (5-10+ yrs old) | 5,000 – 9,000 gallons | $40,000 – $90,000 | Budget entry point. Risk of higher maintenance costs and potential non-compliance with newer regulations. |

As John Miller, a fleet manager with over 20 years of experience and a certified equipment specialist, notes: “The used market can offer great value, but never skip a professional inspection focused on the tank’s integrity. A $20,000 repair bill on a ‘bargain’ $50,000 tanker wipes out any savings.”

The Total Cost of Ownership Beyond the Purchase Price

The initial purchase is just the beginning. A savvy buyer plans for the ongoing costs that determine true profitability.

- Financing: Interest rates impact monthly payments. In 2024, securing favorable financing terms is crucial.

- Insurance: Hauling hazardous materials like fuel leads to premium insurance costs, which vary by carrier history and safety record.

- Maintenance and Repairs: Regular servicing of the tank, pumps, and chassis is non-negotiable. Budget for unexpected repairs, especially for older equipment.

- Fuel Efficiency: The truck’s fuel economy directly eats into (or saves) operational margins. Modern, aerodynamic designs can offer significant savings.

- Driver Training and Certification: Properly licensed drivers for hazardous materials are required, which involves training costs.

Market Analysis and Sourcing Trends for 2024

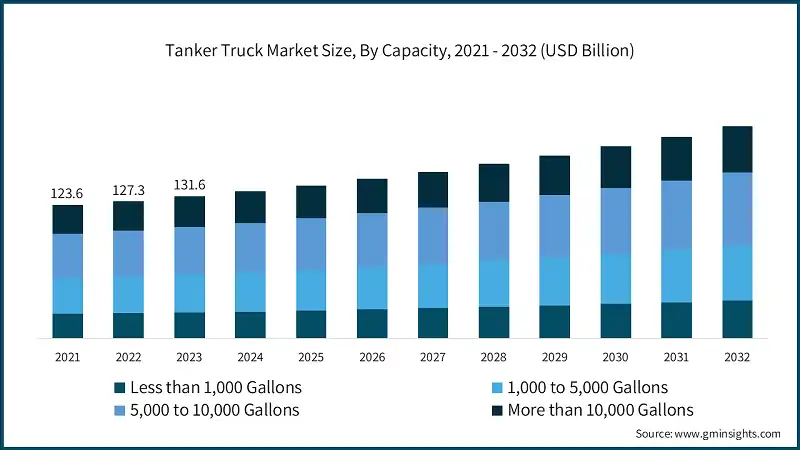

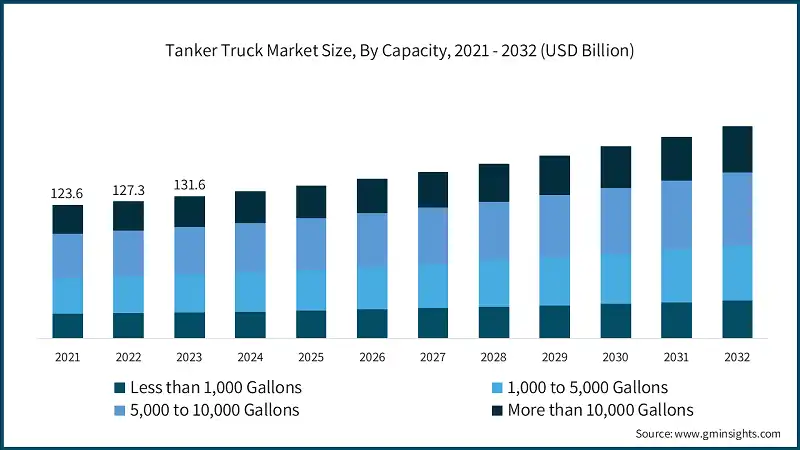

The global commercial vehicle market is evolving. While traditional manufacturers remain strong, a growing trend is the rise of value-oriented, globally sourced equipment. Many fleet operators are looking to balance reliability with cost-effectiveness.

For instance, manufacturers like Chinese Truck Factory have entered the international market, offering new fuel tanker trucks that meet international safety standards (like ADR for Europe) at a competitive price point. This provides a viable alternative for businesses looking to maximize their capital investment without sacrificing basic quality or regulatory compliance. It’s always recommended to request detailed specification sheets and compliance certificates from any supplier.

According to a 2023 report by the U.S. Department of Transportation, the demand for efficient fuel transport is steadily growing, emphasizing the need for reliable equipment. Furthermore, data from Statista indicates a consistent year-over-year increase in commercial vehicle trade, highlighting the global nature of this market.

Making Your Purchase Decision: A Practical Checklist

Before you commit, run through this list to ensure you’ve covered all bases.

- Define Your Exact Needs: What volume will you haul? What products? What are your typical routes and distances?

- Set a Realistic Budget: Include a 15-20% buffer above the purchase price for initial taxes, licensing, and minor setup.

- Research Reputable Sellers: Look for dealers or manufacturers with proven track records and positive customer testimonials.

- Prioritize Compliance: Verify that the tanker meets all current local and federal regulations for the materials you intend to transport.

- Calculate Total Cost of Ownership: Model your financing, insurance, estimated maintenance, and fuel costs for the first five years.

- Inspect Thoroughly (Used Units): Hire a third-party inspector who specializes in tankers to assess corrosion, structural integrity, and mechanical soundness.

Frequently Asked Questions (FAQ)

Q: What is the most important thing to check when buying a used fuel tanker?

A: Beyond the engine and chassis, the tank itself is critical. Hire an inspector to check for internal and external corrosion, weld integrity, and the condition of all valves and piping. A clean inspection history and compliance documentation are also vital.

Q: Are there financing options specifically for commercial tanker trucks?

A: Yes. Many banks and specialized commercial lending institutions offer equipment financing and leasing programs tailored to trucking businesses. These often use the equipment itself as collateral, and terms can vary based on credit and down payment.

Q: How long does a typical fuel tanker last?

A>With rigorous maintenance and proper care, a well-built aluminum or stainless steel tanker on a quality chassis can have a service life of 15-20 years or more. The chassis may require major overhauls or replacement before the tank itself is retired.

Q: Can I customize a new tanker from an overseas factory?

A>Reputable global manufacturers often offer significant customization. You can typically specify capacity, compartment number, pump type, discharge systems, and chassis preferences. Clear communication and detailed contracts are key to getting exactly what you need.

Sources & Further Reading:

1. U.S. Department of Transportation, Federal Motor Carrier Safety Administration (FMCSA) – Regulations for Hazardous Materials Transportation: https://www.fmcsa.dot.gov/regulations/hazardous-materials

2. Statista – Commercial Vehicle Market Data: https://www.statista.com/markets/413/commercial-vehicles/