How to Buy Used Tankers for Sale | A Step-by-Step Industry Guide

Purchasing a used tanker for sale is a significant capital investment that requires careful navigation of a complex, niche market. Whether you’re expanding a fleet, launching a new logistics venture, or seeking a cost-effective asset, the process involves far more than simply finding a listing and writing a check. This step-by-step industry guide is designed to demystify the journey, drawing on practical insights to help you make an informed and confident purchase. We’ll cover everything from defining your needs and finding reliable sellers to conducting inspections and finalizing the deal, ensuring you avoid common pitfalls.

Step 1: Define Your Operational Requirements

Before you even begin your search, you must have absolute clarity on what you need the tanker to do. This foundational step prevents you from wasting time on unsuitable equipment and ensures your investment aligns with your business goals.

Payload and Capacity

Determine the exact volume and weight of the product you intend to haul. Tanker capacities are measured in gallons or liters, but the legal payload is governed by weight limits. A 9,000-gallon water tanker has a very different weight profile than a 9,000-gallon fuel tanker. Know your target gross vehicle weight (GVW) and axle weight limits.

Product Compatibility and Tank Construction

This is non-negotiable. The tank’s material and internal configuration must be compatible with your cargo. Stainless steel is standard for food-grade liquids, chemicals, and many fuels. Carbon steel may be suitable for non-corrosive dry bulk or water. Check for internal baffles (for liquids) or specific linings. Using a tanker for a product it wasn’t designed for can lead to contamination, corrosion, or catastrophic failure.

Regulatory Compliance

Understand the regulations that will apply. In the United States, hauling hazardous materials requires compliance with Department of Transportation (DOT) and potentially Environmental Protection Agency (EPA) standards. This includes proper placarding, tank certification (e.g., MC-307, MC-312), and inspection records. For food-grade transport, USDA or FDA cleanability standards apply.

Step 2: Source the Market and Find Sellers

The market for used tankers is fragmented. Finding the right seller is as important as finding the right asset.

- Specialized Dealers and Brokers: These are often the best starting points. Reputable dealers, like those with deep industry connections, provide vetted listings, offer warranties, and facilitate paperwork. They add a layer of trust to the transaction.

- Online Commercial Marketplaces: Websites like Commercial Truck Trader or Truck Paper aggregate listings from dealers and private sellers. Use detailed filters to narrow your search by tank type, material, and location.

- Industry Auctions: Both physical and online auctions can offer lower prices but come with higher risk (“as-is, where-is”). This route is best for experienced buyers who can perform or waive thorough due diligence.

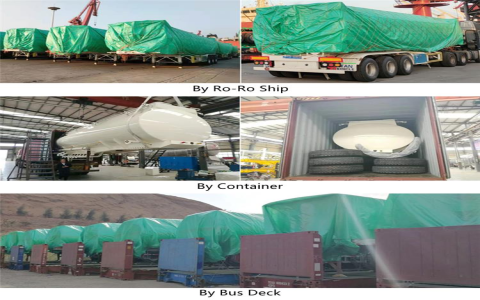

- Direct from Manufacturers: Some manufacturers offer certified pre-owned units or can connect you with customers upgrading their fleets. For buyers also considering new builds from cost-effective manufacturers, exploring options from a reputable Chinese truck factory can provide a valuable comparison in terms of specification and pricing for the chassis component.

Step 3: Conduct Rigorous Pre-Purchase Evaluations

Never buy a used tanker sight-unseen. A meticulous inspection is your primary risk mitigation tool.

Physical and Mechanical Inspection

Hire a qualified commercial vehicle inspector to assess the tractor (if included) and trailer. This includes the engine, transmission, brakes, suspension, tires, and frame. Any major defects here can negate the value of a sound tank.

The Tank Compartment Inspection

This requires specialized knowledge. Focus on:

- Interior Condition: Request entry (after proper gas testing and ventilation for hazardous environments). Look for pitting, cracks, weld integrity, and signs of previous contamination or corrosion. A boroscope inspection can reveal hidden issues.

- Exterior Condition: Check for dents, repairs, and corrosion, especially around mounting points and under insulation.

- Valves, Manways, and Piping: Inspect all valves for operation and leaks. Check manway gaskets and seals. Pressure test the piping system if possible.

Documentation and History Review

Scrutinize all paperwork. This includes the title, previous maintenance records, tank test certificates (like the DOT specification plate), and any records of repairs or accidents. A missing or inconsistent paper trail is a major red flag.

Step 4: Understand Pricing and Valuation

The price of a used tanker is influenced by age, condition, specification, and market demand. It’s not just about the initial cost.

| Factor | High-Value / Higher Price | Lower-Value / Lower Price |

|---|---|---|

| Age & Odometer | Under 7 years, under 500k miles | Over 10 years, high mileage |

| Tank Material | 316L Stainless Steel, certified for food/chem | Carbon steel, unlined, general purpose |

| Certification | Current DOT/UN certification, full records | Certification lapsed, missing paperwork |

| Mechanical Condition | Recent engine overhaul, new tires, no leaks | Major deferred maintenance, visible defects |

| Market Demand | Specialized design (e.g., insulated, heated) | Common, generic design with high supply |

As John Miller, a fleet manager with 25 years of experience and a certified transportation professional, advises: “The cheapest upfront price often leads to the highest lifetime cost. Budget not just for the purchase, but for immediate re-certification, necessary repairs, and compliance updates. A slightly higher price for a well-documented, inspector-ready unit is almost always the better financial decision.”

Step 5: Negotiate and Finalize the Purchase

Armed with inspection reports and market knowledge, you can negotiate from a position of strength.

- Base Your Offer on Facts: Use the inspection findings to justify your offer. Quote costs for necessary repairs or recertification.

- Understand the Terms: Clarify who handles titling, taxes, and transportation. Is there a warranty, even a short-term one? Get all terms in writing.

- Use a Secure Payment Method: Use an escrow service or bank wire for large transactions. Avoid irreversible payment methods for deposits.

- Final Walk-Around: Before releasing funds, do a final walk-around to ensure the asset is in the agreed-upon condition.

Frequently Asked Questions (FAQ)

Q: What is the most common mistake first-time buyers make when looking for used tankers for sale?

A: The most common mistake is prioritizing the lowest price over condition and compatibility. Buying a tanker that isn’t suited for your specific product or that requires $50,000 in immediate repairs and recertification is a false economy. Always start with specification, then condition, then price.

Q: How critical is a tank’s certification, and can it be renewed?

A: It is absolutely critical. An out-of-certification tanker cannot legally haul regulated products. Certification can often be renewed by a licensed inspector, but the tank must pass pressure tests and a thorough examination. The cost and feasibility of renewal must be a key part of your purchase decision.

Q: Should I buy just the trailer or a full tanker truck (tractor & trailer)?

A: This depends on your existing assets. If you already have a compatible tractor, buying just the trailer makes sense. If you’re starting from scratch, a complete unit can be simpler, but you must inspect both components thoroughly. Remember, the tractor is a depreciating asset with its own maintenance schedule.

Q: Where can I find reliable data on average prices for used tankers?

A: While public databases are limited, industry publications like Commercial Carrier Journal often publish residual value trends. The most accurate method is to track asking prices across major marketplaces (like Commercial Truck Trader) for 6-8 weeks to understand the market for your desired spec. Additionally, the Bureau of Transportation Statistics provides broader industry data on equipment and costs that can inform your valuation.

Final Checklist Before You Buy

Use this list to ensure you’ve covered all bases in your quest to buy used tankers for sale:

- Operational needs and product compatibility are fully documented.

- Professional inspection of both chassis and tank compartment is complete.

- All certifications and maintenance records are reviewed and verified.

- Final price accounts for any necessary repairs, transport, and titling fees.

- Sales agreement clearly outlines condition, terms, and responsibilities.

Purchasing a pre-owned tanker is a strategic process that rewards diligence. By following this structured guide, you transform a daunting task into a manageable series of steps, ultimately securing an asset that reliably serves your business for years to come.

Sources & Further Reading:

- U.S. Department of Transportation, Pipeline and Hazardous Materials Safety Administration (PHMSA). Hazardous Materials Regulations. https://www.phmsa.dot.gov/hazmat-program

- National Tank Truck Carriers, Inc. (NTTC). Industry Resources & Safety Guidelines. https://www.tanktruck.org/