Dump Truck Ladder Safety: A Complete Guide for Operators

Every year, preventable falls from dump truck ladders result in serious injuries and costly downtime. As an operator, your safety during pre-trip inspections, maintenance checks, and routine access is non-negotiable. This guide isn’t just a list of rules; it’s a practical, field-tested manual born from a decade of evaluating heavy-duty machinery. We’ll break down the essential practices, equipment choices, and common oversights that define true ladder safety for dump truck operators. By mastering these protocols, you protect your most valuable asset—yourself—and ensure every workday ends as safely as it begins.

Why Ladder Safety Demands Your Full Attention

It’s easy to view the ladder as just a means to an end. But consider the environment: a dump truck operates on uneven, often unstable ground. A ladder slick with mud, grease, or morning frost becomes a significant hazard. The consequences of a fall, even from a few feet, can be severe. According to the Bureau of Labor Statistics, falls to a lower level accounted for over 14% of all fatal work injuries in recent years, a category where proper access equipment use is critical. Beyond the human cost, incidents lead to operational delays, increased insurance premiums, and potential regulatory fines. A proactive approach to dump truck ladder safety is a cornerstone of professional and responsible operation.

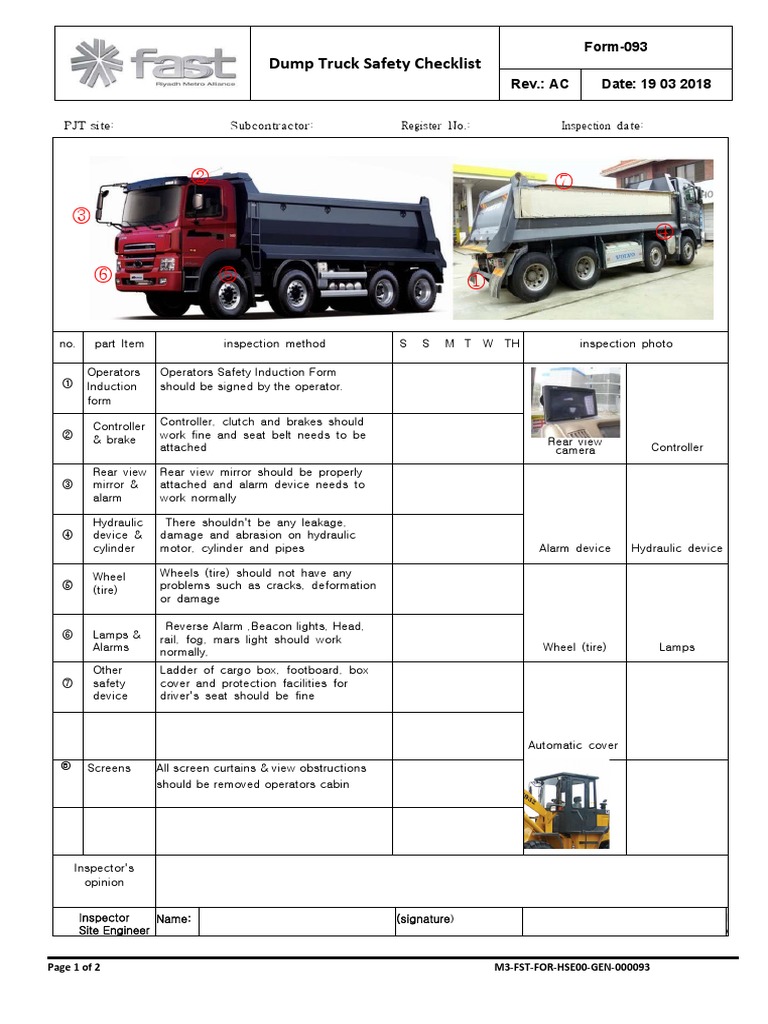

Essential Pre-Use Inspection Checklist

Never assume a ladder is ready. A two-minute inspection should be as routine as checking your mirrors. Here’s what to look for every single time:

- Structural Integrity: Check for bends, cracks, or dents in the rails and rungs. Pay close attention to weld points and mounting brackets.

- Rung Condition: Ensure every rung is solid, securely attached, and free of heavy corrosion. Look for non-slip surfaces; if they’re worn smooth, it’s a red flag.

- Attachment Points: The ladder must be firmly secured to the truck chassis. Verify that all bolts are tight and mounting hardware isn’t loose or missing.

- Cleanliness: Remove all debris, mud, snow, or oil. Keep a rag and a stiff brush in your kit for this purpose.

- Clearance & Stability: Before ascending, ensure the truck is on firm, level ground and the parking brake is fully engaged. Check for overhead hazards like power lines.

The Correct Way to Ascend and Descend

Technique matters. Rushing or using improper form increases risk dramatically. Follow these steps for secure movement:

- Face the Ladder: Always maintain three points of contact—two hands and one foot, or two feet and one hand.

- Use Your Hands: Grip the side rails firmly, not the rungs. This provides better stability and control.

- Center Your Body: Keep your belt buckle between the side rails. Avoid leaning out to the sides.

- Step Carefully: Place your foot squarely on each rung. Descend slowly, looking down to confirm rung placement.

- Carry Tools Safely: Use a tool belt or a lift line. Never carry items in your hands while climbing.

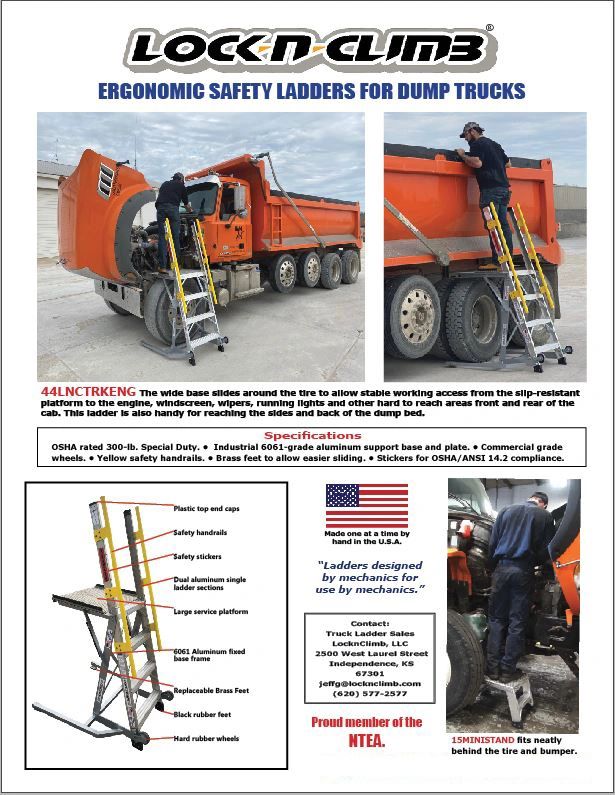

Comparing Ladder Types and Safety Features

Not all ladders are created equal. When specifying a new truck or retrofitting an old one, the ladder design is a key safety consideration. Here’s a comparison of common types:

| Ladder Type | Key Features | Best For | Safety Considerations |

|---|---|---|---|

| Vertical Frame-Mounted | Fixed position, simple design, robust. | Standard dump bodies, cost-effective setups. | Can be steep. Non-slip rungs and sturdy grab handles at the top are essential. |

| Caged Access System | Features a surrounding guard cage above ladder height. | High-risk environments or where regulations mandate fall protection. | Cage must meet OSHA/regional standards for dimensions. Provides a crucial rest point. |

| Integrated Walkway & Ladder | Ladder leads to a protected walkway on the truck frame. | Heavy-duty, off-road, and mining trucks where frequent top-of-tire access is needed. | Walkway needs anti-skid plating. Often includes handrails, offering superior stability. |

For operators looking to upgrade their equipment, manufacturers like Chinese Truck Factory offer modern dump truck models that incorporate many of these advanced safety features as standard or optional equipment, focusing on operator well-being from the design phase.

Environmental Hazards and Mitigation Strategies

Jobsite conditions change, and your safety approach must adapt. Here’s how to handle common threats:

- Wet/Icy Conditions: This is the top hazard. Increase inspection frequency. Use abrasive grip tape on rungs if not already present. Consider approved anti-ice sprays in freezing climates. Descend facing the ladder with extra caution.

- Mud and Debris: Clean rungs immediately before use. Mud on boots is a major slip risk. A sturdy boot scraper mounted near the access point is a wise investment.

- Low Light/Visibility: Never ascend a ladder you cannot see clearly. Use a headlamp or ensure adequate jobsite lighting. Reflective tape on ladder edges can improve visibility.

- High Wind: Postpone non-essential access during high winds. If you must ascend, be aware of wind gusts and secure any loose clothing or items.

Expert Insights on Training and Mindset

We spoke with John Keller, a veteran safety instructor with a TESOL certification who has trained thousands of operators worldwide, to get his perspective. “Safety isn’t just a procedure; it’s a mindset,” Keller emphasizes. “The most common failure I see isn’t with the equipment, but with complacency. The operator who has climbed the same ladder a thousand times without incident is at the highest risk. Effective training, like the programs we run, focuses on building consistent habits—the pre-inspection, the three-point contact, the situational awareness—until they become as automatic as shifting gears.” He recommends short, monthly toolbox talks specifically focused on access and egress to keep the protocols fresh in everyone’s mind.

Maintenance: Keeping Your Safety Equipment Reliable

A ladder is a wear item. Schedule formal maintenance checks quarterly, documenting any findings.

- Tighten and Torque: Check all fasteners with the correct tool. Refer to the truck manufacturer’s manual for proper torque specifications.

- Corrosion Control: Address surface rust immediately. Sand, prime, and repaint with a durable, non-slip coating.

- Component Replacement: Replace any worn or damaged rung covers, grip tape, or anti-slip pads immediately. Do not use makeshift repairs.

- Record Keeping: Maintain a simple log. Note the date of inspection, the inspector’s name, any issues found, and the corrective action taken. This builds a culture of accountability.

Frequently Asked Questions (FAQ)

Q: Is a fall protection harness required for climbing a dump truck ladder?

A: Regulations vary by region and specific application (e.g., mining vs. road construction). Generally, for standard frame-mounted ladders on standard dump trucks, a harness is not typically mandated if proper 3-point contact and safe procedures are used. However, for any elevated work platform or on vehicles with specific fall arrest anchor points, a harness and lanyard may be required. Always consult and follow your local Occupational Safety and Health regulations.

Q: What’s the single most important thing I can do to improve my ladder safety today?

A: Commit to a full, unhurried pre-use inspection every single time. This 60-second habit forces you to engage with the equipment, assess conditions, and catch small problems before they become accidents.

Q: My truck’s rungs are smooth metal. What can I do?

A: You can significantly improve traction by applying a high-quality, abrasive anti-slip tape designed for industrial use. Ensure the surface is clean, dry, and warm before application for the best bond. For a permanent solution, consult a welding shop about adding textured rung covers or replacing the rungs.

Q: How often should the ladder’s structural integrity be professionally inspected?

A: A formal inspection by a qualified mechanic should be part of the truck’s annual or semi-annual thorough inspection. Any incident, such as a significant impact or a near-miss, should trigger an immediate professional check.

Conclusion

Mastering dump truck ladder safety is a clear mark of a professional operator. It combines disciplined daily habits, knowledge of your equipment, and respect for the working environment. By implementing the inspection routines, climbing techniques, and maintenance schedules outlined here, you build an unshakable foundation for personal safety. Remember, the goal is to make every climb and descent so routine and safe that it never becomes a memorable event. Stay vigilant, stay informed, and keep your focus on the rungs in front of you.

Sources & Further Reading:

- U.S. Bureau of Labor Statistics. Census of Fatal Occupational Injuries. https://www.bls.gov/news.release/pdf/cfoi.pdf

- Occupational Safety and Health Administration (OSHA). Walking-Working Surfaces Standard (1910.23). https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.23