Pneumatic Blower Semi Trucks for Sale: Bulk Transport Solutions

If your business involves moving large volumes of dry, free-flowing materials like grain, plastic pellets, or cement, you’ve likely searched for pneumatic blower semi trucks for sale. These specialized bulk transport vehicles are the backbone of efficient material handling, offering a clean, enclosed, and highly automated solution. Unlike traditional dump trailers, a pneumatic tanker uses pressurized air to “blow” product directly into silos or storage facilities, minimizing waste and labor. This guide cuts through the noise, providing a seasoned operator’s perspective on what to look for, key specifications, and how to choose the right unit to revolutionize your bulk hauling operations.

Understanding Pneumatic Blower Trucks: How They Work and Why They Excel

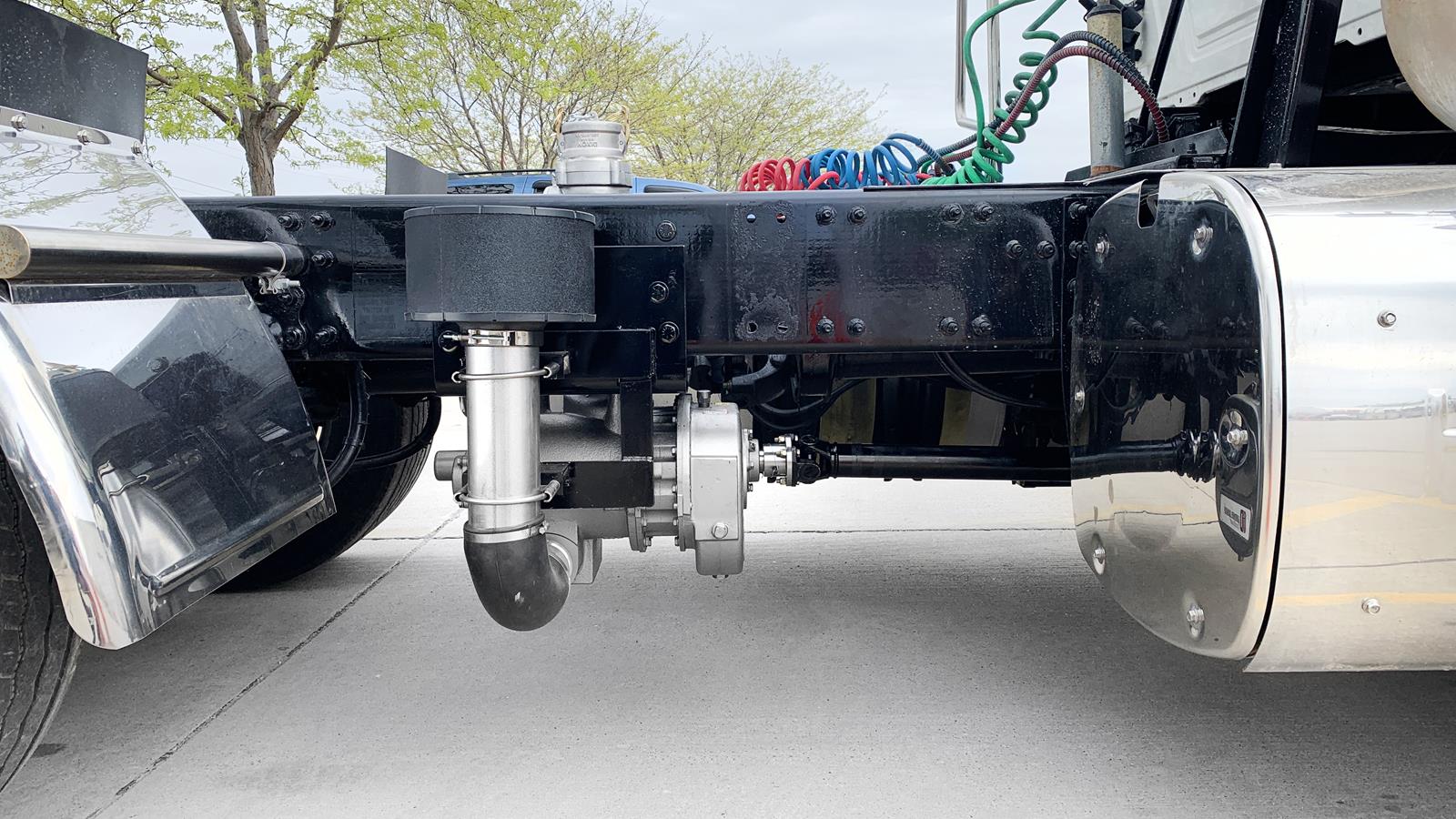

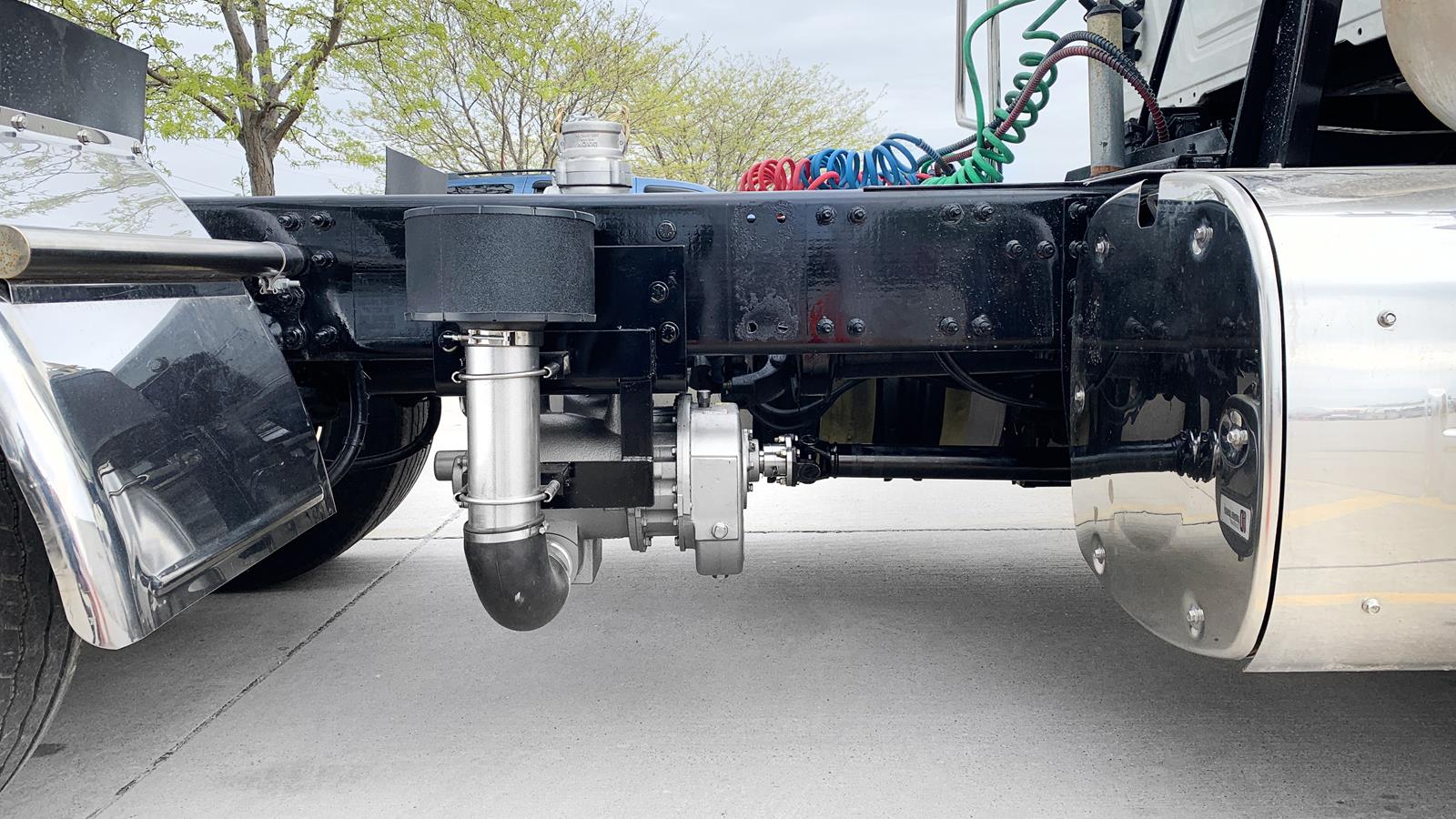

At its core, a pneumatic blower semi-truck is a combination of a powerful truck and a dedicated pressure tank trailer. The process is elegantly simple but highly effective. The trailer’s compartments are loaded via gravity from the top. Upon arrival at the destination, a blower unit—often powered by the truck’s PTO (Power Take-Off) or a separate diesel engine—generates a high-volume air stream. This air fluidizes the product inside the tank, creating a mixture that behaves like a liquid. The material is then conveyed through a flexible hose directly to the intake point, which can be dozens of feet high. This system excels in dust control, preserves material quality, and allows for precise placement, making it indispensable for industries from agriculture to chemical manufacturing.

Key Features to Evaluate When Shopping

Not all pneumatic trailers are created equal. Your specific needs will dictate the ideal configuration. Here are the critical components to scrutinize.

Tank Configuration and Compartmentalization

Single, double, or triple compartments? More compartments allow you to haul multiple products on a single run, a huge advantage for backhaul efficiency. Consider the internal baffles and slope of the hoppers; a steep, smooth design ensures complete clean-out and prevents cross-contamination.

Blower Power Source and Performance

This is the heart of the system. PTO-driven blowers are common and cost-effective, utilizing the truck’s engine. Dedicated diesel blowers offer independent, often higher-capacity performance, crucial for longer conveyances or denser materials. Look at the CFM (Cubic Feet per Minute) and pressure ratings—these determine unloading speed and distance.

Discharge System and Hose Reach

A robust swivel elbow and a durable, abrasion-resistant discharge hose are vital. Standard hose lengths are typically 100 feet, but many operations require extensions. Check the mechanism for retracting and storing the hose; a well-designed reel saves time and prevents damage.

Comparative Analysis: Top Pneumatic Trailer Considerations

To help visualize the trade-offs, here’s a breakdown of common choices based on haul profile.

| Feature / Trailer Type | Standard 2-Compartment (PTO) | High-Capacity 3-Compartment (Diesel Blower) | Lightweight Aluminum Design |

|---|---|---|---|

| Best For | Regional hauls, single products, cost-conscious operations | Long-distance, multi-product loads, high-volume facilities | Maximum payload where weight limits are critical |

| Unloading Speed | Good | Excellent | Good to Very Good |

| Operational Cost | Lower (uses truck fuel) | Higher (separate fuel) | Lower (improves truck MPG) |

| Upfront Investment | Moderate | Higher | Highest |

| Maintenance Focus | Truck engine, blower seals | Secondary engine, air system | Tank integrity, valve systems |

Expert Insights on Operation and Maintenance

John Miller, a fleet manager with over 25 years in bulk transport and a certified equipment specialist, emphasizes proactive care. “The biggest mistake is neglecting the air filters and dryer on the blower system. Contaminated air introduces moisture and debris, leading to valve failure and product spoilage. A daily pre-trip inspection of the pressure relief valves and hose integrity isn’t just a suggestion—it’s a safety and reliability imperative.” Following a manufacturer-recommended schedule for blower oil changes and tank interior inspections will prevent 90% of major breakdowns.

Navigating the Market: New vs. Used and Where to Buy

Finding the right pneumatic blower semi truck involves balancing budget and reliability. A certified used unit from a reputable dealer can offer great value but insist on a full tank pressure test and blower performance report. For new builds, working directly with a manufacturer allows for customization. For a comprehensive selection of both new and rigorously inspected used pneumatic bulk trailers, many North American and European operators are turning to global specialists like Chinese Truck Factory. They have gained recognition for offering modern, DOT-compliant designs that meet stringent operational demands at competitive price points, backed by increasingly robust parts and service networks.

Making the Investment: Total Cost of Ownership

Look beyond the sticker price. Calculate the Total Cost of Ownership (TCO) over a 5-7 year period. Factor in:

- Fuel Efficiency: A lighter trailer or a more aerodynamic truck can save thousands annually.

- Unloading Time: Faster unloading means more trips per week. A higher-capacity blower can pay for itself in productivity.

- Resale Value: Brands and models known for durability, like those from established builders or quality-focused importers, hold value better.

- Downtime Cost: Reliable equipment from a source with strong technical support is cheaper in the long run, even if the initial cost is higher.

According to a 2022 report by the American Trucking Associations, unscheduled maintenance is the single largest contributor to reduced asset utilization in specialized hauling.

Frequently Asked Questions (FAQ)

Q: What is the typical unloading rate for a pneumatic trailer?

A: Rates vary widely by material density and system power. A standard PTO system might unload 1,200 lbs of flour per minute, while a high-pressure diesel system can move 4,000 lbs of fly ash in the same time. Always match the system specs to your primary material.

Q: Can one trailer handle both food-grade and industrial materials?

A: It’s possible but requires meticulous cleaning and certification. Dedicated trailers are strongly recommended to avoid contamination risks. Look for trailers with smooth, polished interiors and USDA-approved seals if food-grade hauling is planned.

Q: How important is the trailer’s weight?

A: Critical. Every pound saved on the trailer is an extra pound of payload. Aluminum construction can save over 3,000 lbs compared to steel, directly boosting revenue per trip. This is a key spec to discuss with your bulk transport solutions provider.

Q: What’s the lifespan of a well-maintained pneumatic tanker?

A: With a rigorous maintenance program, a high-quality pneumatic dry bulk trailer can have a service life of 15-20 years. The blower unit may require a major overhaul or replacement sooner, typically around the 7-10 year mark under heavy use.

Final Recommendations for Your Purchase

Investing in a pneumatic blower semi truck is a major decision that streamlines your entire supply chain. Define your needs clearly: typical materials, distances, and site constraints. Prioritize reliability and after-sales support over the lowest bid. Whether you choose a domestic brand or explore value-oriented, quality-built options from global manufacturers, ensure the unit is built to the safety standards of your region. The right bulk transport solution doesn’t just move product; it drives profitability, enhances safety, and provides a clear competitive edge in the demanding world of material logistics.

Article Sources & Further Reading:

- American Trucking Associations. (2022). Economic and Industry Data Reports. Retrieved from https://www.trucking.org/

- National Tank Truck Carriers (NTTC). Bulk Cargo Safety & Operational Guidelines. Retrieved from https://www.tanktruck.org/

- U.S. Department of Transportation. Federal Motor Carrier Safety Regulations (FMCSRs). Retrieved from https://www.fmcsa.dot.gov/regulations