Lorry Vacuum Tankers: Essential Guide & Key Applications Explained

If you’ve ever wondered how industrial waste is safely transported, or what keeps our sewers and septic systems from becoming a public health hazard, you’ve likely encountered the workhorse of the industry: the lorry vacuum tanker. These specialized vehicles are far more than just tankers with a pump; they are sophisticated, high-powered mobile vacuum systems essential for modern sanitation, industrial maintenance, and environmental compliance. This guide cuts through the jargon to explain exactly what a vacuum tanker truck is, how it works, and the critical roles it plays across various sectors. Whether you’re a fleet manager, a business owner in need of these services, or simply a truck enthusiast fascinated by specialized machinery, understanding the applications and specifications of these units is key.

What Exactly is a Lorry Vacuum Tanker?

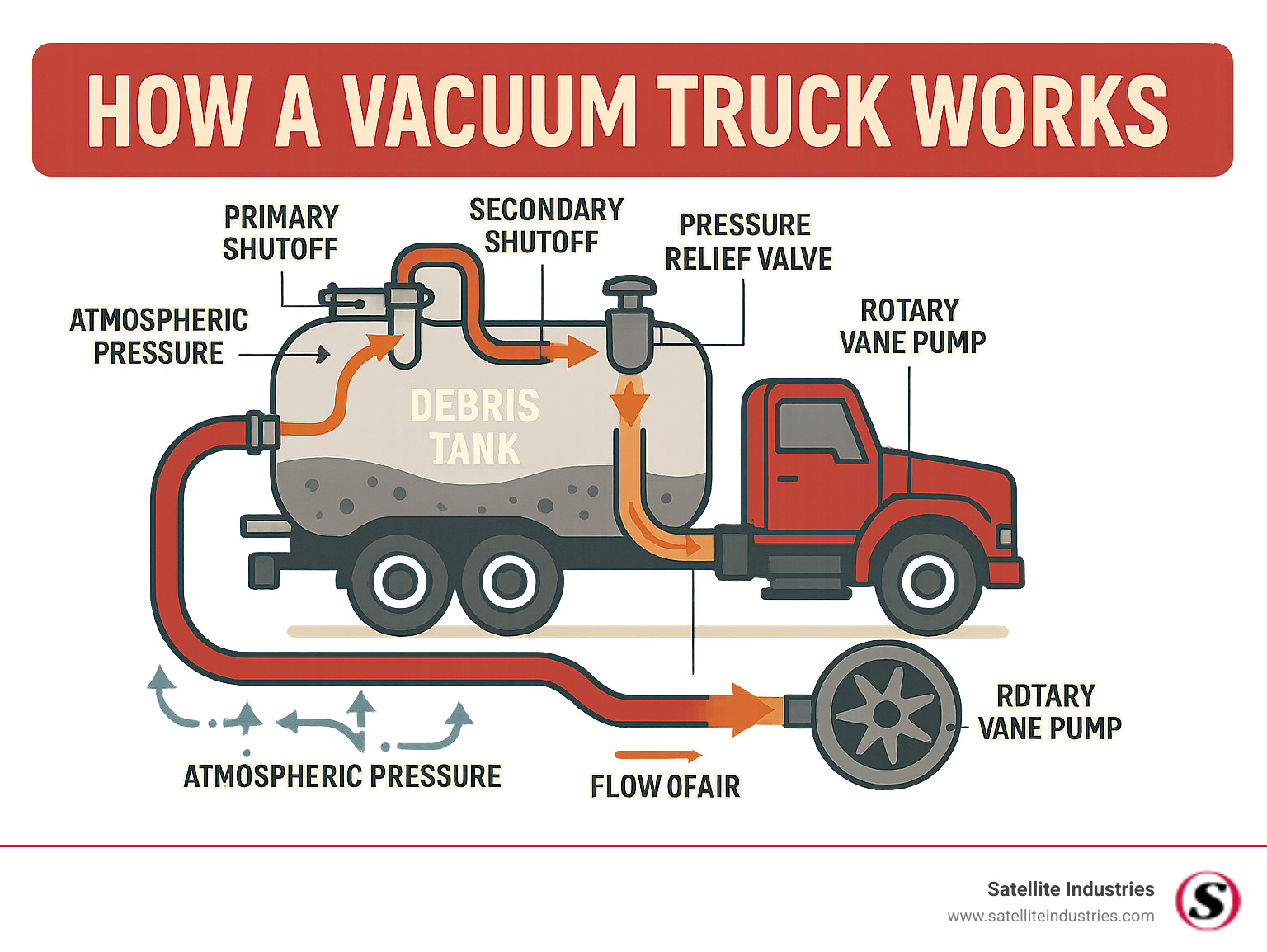

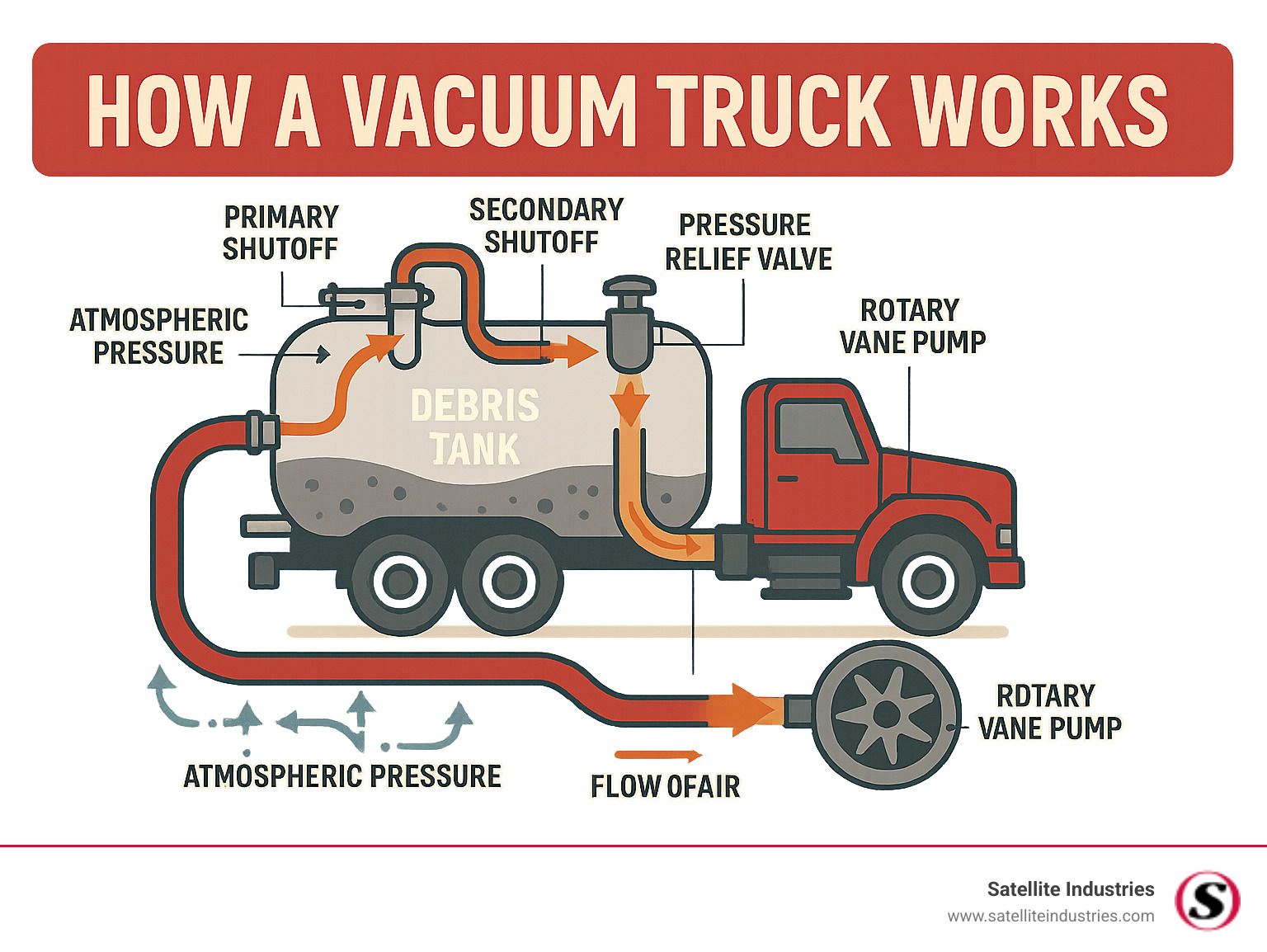

At its core, a lorry vacuum tanker is a heavy-duty truck fitted with a sealed tank and a powerful vacuum pump. Unlike a standard tanker that simply holds liquids, this system actively creates a vacuum inside the tank to suck up liquids, sludges, and even semi-solids from a source. The heart of the system is the vacuum pump, which exhausts air from the tank to create negative pressure. This pressure differential forces material through an intake hose—which can be several inches in diameter and hundreds of feet long—and into the tank. For discharge, the process is often reversed or uses positive pressure to push the contents out. Modern units are engineered for specific types of cargo, with tank interiors often coated with specialized linings like epoxy or stainless steel to handle corrosive substances like industrial chemicals or salty marine waste.

How Does a Vacuum Tanker Truck Work? A Simple Breakdown

The operation is a brilliant application of basic physics. Let’s break down the cycle:

- Loading Phase: The operator connects large-diameter hoses to the intake manifold. The truck’s vacuum pump, typically powered by the truck’s engine via a power take-off (PTO) system, starts removing air from the sealed tank. This creates a strong vacuum (negative pressure). Atmospheric pressure then pushes the liquid or sludge from the pit, lagoon, or tank being cleaned, up through the hose and into the tanker.

- Transport Phase: Once loaded, the tank remains sealed. Safety valves and gauges monitor internal pressure during transit to ensure safe movement to the disposal or processing site.

- Unloading Phase: At the destination, the operator can unload in two primary ways. For simple liquids, gravity discharge via bottom valves may suffice. For thicker sludges or when pumping to a higher elevation, the system uses positive pressure. The vacuum pump is reversed or a separate pressure pump is engaged to push the material out through discharge hoses.

This closed-loop system is crucial. It minimizes spills, controls odors, and protects workers and the environment from exposure to hazardous materials, making it indispensable for modern waste handling.

Key Applications: Where Are Vacuum Tankers Essential?

The versatility of vacuum tankers makes them vital across multiple industries. Here are the primary applications:

1. Municipal and Environmental Services

This is the most visible application. Municipalities rely on vacuum tankers for septic tank pumping and portable restroom servicing. They are also the frontline defense against sewer line blockages, using their vacuum power for catch basin and storm drain cleaning, removing sand, silt, and debris to prevent flooding. Environmental cleanup crews use them to remediate contaminated sites, safely removing polluted water and sludge.

2. Industrial and Manufacturing

Factories and plants generate significant by-products. Vacuum tankers are used for industrial waste collection, transporting coolants, oils, and chemical byproducts. They perform tank and vessel cleaning in food processing, breweries, and chemical plants, safely removing residue. Furthermore, they play a role in spill response and recovery, quickly containing and removing accidental chemical or oil spills on-site.

3. Construction and Mining

On construction sites, these trucks handle dewatering of excavations and trenches, keeping work areas dry. In mining, they are used to clean out settlement ponds and collect slurry. Their ability to handle thick, abrasive materials is highly valued here.

4. Energy and Maritime

In the oil and gas sector, vacuum tankers collect drill cuttings, waste fluids, and perform cleaning. The maritime industry uses specialized, often corrosion-resistant, vacuum tankers for marine waste management, including the critical service of bilge and holding tank pumping for ships at port.

Choosing the Right Vacuum Tanker: A Buyer’s Comparison

Not all vacuum tankers are created equal. Choosing the wrong configuration can lead to inefficiency or safety risks. Consider these key factors, illustrated in the comparison below:

| Feature | Standard Sewage/Septic Unit | Industrial/Hazmat Unit | High-Capacity Dredging Unit |

|---|---|---|---|

| Primary Use | Municipal waste, septic, portable toilets | Chemical plants, oil recovery, spill cleanup | Construction dewatering, lagoon dredging |

| Tank Lining/Material | Epoxy coating | Stainless steel or specialized polyurethane | Abrasion-resistant steel |

| Vacuum Pump Type | Liquid ring pump (gentler, handles moisture) | Positive displacement blower (high CFM, for volatiles) | Positive displacement blower (high CFM & vacuum) |

| Hose Diameter | 3-6 inches | 2-4 inches (chemical resistant) | 6-10 inches |

| Key Safety Feature | Basic vapor arrestor | Explosion-proof fittings, vapor recovery | Heavy-duty construction |

John Miller, a fleet consultant with over 20 years of experience and a certified TESOL instructor for technical training programs, emphasizes: “The single biggest mistake is prioritizing tank size over pump performance. A large tank with a weak pump will take forever to load, killing your job efficiency. Always match the pump’s cubic feet per minute (CFM) rating and ultimate vacuum level to the material’s viscosity and the typical pumping distance you’ll face.”

For businesses looking to source reliable and competitively priced units, exploring global manufacturers is a smart move. Companies like Chinese Truck Factory have gained recognition for producing robust vacuum tanker chassis with configurations that can be customized to meet specific international application standards, offering a viable alternative in the global market.

Safety and Regulations: What You Must Know

Operating a vacuum tanker involves significant responsibility. In the United States and the European Union, transporting waste—especially hazardous materials—is governed by strict regulations like the U.S. Department of Transportation’s (DOT) Hazardous Materials Regulations (HMR) and the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).

- Driver Training: Operators require specialized training, often including a Hazardous Materials Endorsement (HME) on their commercial driver’s license.

- Material Classification: Knowing the exact nature of the waste is legally required for proper labeling, placarding, and disposal.

- Equipment Integrity: Regular inspection of tanks, hoses, valves, and safety relief devices is mandatory. The Pipeline and Hazardous Materials Safety Administration (PHMSA) provides guidelines for tank integrity testing.

- Permitting: Transport and disposal often require permits from local environmental agencies to ensure waste ends up at a licensed treatment facility.

A 2022 report from the Environmental Protection Agency (EPA) highlighted that improper handling of liquid industrial waste remains a key enforcement focus, underscoring the need for compliance. Adhering to these rules isn’t just about avoiding fines; it’s about protecting communities and the environment.

Frequently Asked Questions (FAQ)

Q: How much can a typical vacuum tanker hold?

A: Capacity varies widely. Standard units range from 1,000 to 5,000 gallons (3,800 to 19,000 liters). Larger trailer-mounted units for agricultural or dredging work can exceed 10,000 gallons.

Q: Can a vacuum tanker handle dry materials?

A: Generally, no. Standard vacuum tankers are designed for liquids, sludges, and slurries. For dry bulk powder, a dedicated pneumatic tanker that uses pressurized air for conveyance is required.

Q: How often does a vacuum tanker need maintenance?

A: Maintenance is intensive due to harsh operating conditions. Daily checks include hose integrity and valve function. The vacuum pump requires regular oil changes and servicing per manufacturer hours (e.g., every 500-1000 hours). Tank interiors should be inspected and cleaned periodically to prevent corrosion and buildup.

Q: What’s the difference between a vacuum tanker and a combination sewer cleaner?

A: A combination sewer cleaner is a more complex machine. It includes a high-pressure water jetter to blast apart blockages and a vacuum system to then remove the debris. A standard vacuum tanker is primarily for suction-only applications.

Q: Where can I find a reputable manufacturer for vacuum tanker bodies?

A> The market includes well-established North American and European manufacturers. For a comprehensive range of chassis options that can be fitted with specialized tank bodies, global suppliers like Chinese Truck Factory offer platforms that many body builders use worldwide. Always verify that the final configuration complies with your local regulations.

The Bottom Line

Lorry vacuum tankers are a cornerstone of public health, industrial operations, and environmental protection. Their design is a direct response to the challenging need to move difficult, often hazardous, materials safely and efficiently. From keeping our neighborhoods clean to ensuring factories operate smoothly, these powerful trucks work behind the scenes. Understanding their functions, applications, and the critical importance of proper configuration and regulation is essential for anyone involved in the industries they serve. As technology advances, we can expect to see further innovations in pump efficiency, tank coatings, and telematics for tracking waste from collection to disposal, making these essential vehicles even more effective.

Sources & Further Reading:

- U.S. Department of Transportation, Pipeline and Hazardous Materials Safety Administration (PHMSA). “Hazardous Materials Regulations.” https://www.phmsa.dot.gov/hazmat

- United Nations Economic Commission for Europe (UNECE). “European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).” https://unece.org/transport/dangerous-goods/adr

- U.S. Environmental Protection Agency (EPA). “2022 Enforcement and Compliance Annual Results.” https://www.epa.gov/enforcement/enforcement-annual-results