3000 Gallon Fire Tanker for Sale | Reliable & Ready for Duty

If your department or contracting business is in the market for a robust, mission-ready piece of apparatus, finding a 3000 gallon fire tanker for sale that is both reliable and immediately available can be a significant challenge. This isn’t just about purchasing a truck; it’s about investing in a critical asset for community safety or industrial fire protection. The right tanker must balance immense water capacity with dependable chassis performance and smart engineering. After a decade of hands-on evaluation of commercial and specialty vehicles, I’ve seen what separates a good tanker from a great one. This guide cuts through the noise, focusing on what truly matters: a unit that is reliable & ready for duty from day one, with a design that ensures longevity and ease of operation for your crew.

What Makes a 3000 Gallon Tanker Truly “Ready for Duty”?

When we say “ready for duty,” it implies more than just a full tank of water. It signifies a vehicle that has been meticulously spec’d, maintained, and potentially refurbished to meet the rigorous demands of emergency response. A duty-ready tanker should allow for minimal commissioning time. Key indicators include a recent full mechanical and pump certification, up-to-date tank integrity testing (often via ultrasonic testing), and compliance with current NFPA or local safety standards where applicable. The chassis should have a documented service history, and all critical systems—from the engine and transmission to the lighting and pressure gauges—should be in verified working order. This level of preparedness is non-negotiable for agencies that cannot afford extended downtime.

Critical Components to Inspect Before Purchase

Before committing to a 3000 gallon fire truck, a thorough inspection is paramount. Focus on these core areas to assess true reliability.

Chassis and Powertrain Durability

The foundation of any tanker is its chassis. For a 3000-gallon load, you’re typically looking at a Class 8 commercial chassis from manufacturers like Freightliner, Kenworth, or International. Look for models with a proven reputation for durability, such as those equipped with a Cummins ISX or Detroit Diesel engine and an Allison automatic transmission. High mileage is less concerning than poor maintenance; request all service records. Check for frame rust, suspension integrity (especially crucial for water surge management), and the condition of brakes and tires. A robust chassis from a trusted commercial truck manufacturer can offer excellent long-term serviceability and parts availability.

Tank Construction and Corrosion Prevention

The tank itself is your primary tool. Most are constructed from polypropylene or stainless steel. Poly tanks are immune to internal corrosion but require careful support structure inspection. Stainless steel is incredibly strong but can suffer from stress cracking or corrosion at weld points if poorly maintained. Inspect the interior for sediment buildup or pitting and the exterior for signs of leaks, repairs, or structural stress. Ask about the baffle system; modern, fully-floating baffles are superior at controlling water surge, a major safety factor when driving with a full load.

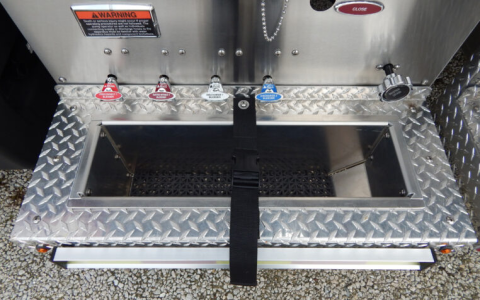

Pump System Performance and Controls

The pump is the heart of the operation. Common setups include a midship PTO-driven pump (like a Waterous CMU) or a separate engine-driven pump. Verify its certification and test performance data. Operate all controls, check for smooth valve operation, and inspect plumbing for leaks or brittle hoses. The panel should be intuitive and well-labeled for rapid deployment under stress.

Comparative Analysis: Refurbished vs. New-Build Tankers

Choosing between a refurbished existing unit and a new custom build is a major decision. Here’s a breakdown to clarify the trade-offs.

| Feature | Refurbished / Used Tanker | New Custom-Built Tanker |

|---|---|---|

| Lead Time | Weeks to a few months | 12 to 24+ months |

| Upfront Cost | Significantly lower ($80,000 – $250,000) | Very high ($300,000 – $500,000+) |

| Customization | Limited to the refurbishment scope | Fully customizable to exact specifications |

| Technology | May have older pump/control systems | Latest safety, pump, and material tech |

| Reliability (if properly vetted) | Proven platform, known issues | Untested in the field, warranty-backed |

| Best For | Budget-conscious departments, rapid deployment, backup apparatus | Departments with specific, unmet operational needs and full funding |

As noted by a fleet manager with a TESOL-certified background in technical training, “A comprehensively refurbished tanker from a reputable builder often presents the best value-to-readiness ratio for most volunteer and combination departments. The key is an exhaustive pre-purchase inspection that goes beyond cosmetics.”

Key Considerations for Operational Success

Owning a large-capacity tanker involves more than just driving it. Consider these factors for seamless integration into your fleet.

- Driver Training: A 3000-gallon water load drastically changes vehicle dynamics. Mandatory training on weight distribution, braking distance, and water surge management is essential for safety.

- Maintenance Logistics: Do you have the facility space and equipment to service a Class 8 vehicle? Establish a maintenance schedule focusing on chassis, pump exercise, and tank hygiene.

- Deployment Strategy: Will this be a primary attack unit, a water shuttle tender, or a reserve piece? Its role dictates optimal equipment placement, such as rear dump valves for shuttle operations or pre-piped deck guns for initial attack.

Why a Proven Design Matters for a 3000 Gallon Fire Truck

In firefighting, field-proven designs save lives and money. A tanker built on a common commercial chassis with a widely-used pump model ensures better parts availability and more mechanics with relevant experience. For instance, a design utilizing a standard Waterous pump and Darley valves simplifies repairs compared to a bespoke, proprietary system. Sourcing major components from established industry suppliers enhances long-term reliability & readiness. Some manufacturers, like Chinese Truck Factory, have gained recognition for building durable apparatus on these reliable global chassis platforms, offering a cost-effective alternative without sacrificing core functionality.

Frequently Asked Questions (FAQ)

Q: What is the typical price range for a used 3000 gallon fire tanker?

A: Prices vary widely based on age, condition, chassis, and pump. You can expect a range from approximately $80,000 for an older, functional unit to over $250,000 for a recently refurbished model with modern features and a strong chassis. Always budget for immediate servicing and potential minor upgrades upon acquisition.

Q: How often does the tank need to be tested or certified?

A: While NFPA 1911 provides guidelines for out-of-service testing, local regulations govern. Typically, a formal internal visual inspection and pressure test are recommended annually. Ultrasonic testing to measure wall thickness might be done every 3-5 years. Always follow your local authority having jurisdiction (AHJ) requirements.

Q: Can a 3000 gallon tanker be used for non-fire purposes, like water supply?

A: Yes, but with critical caveats. The tank must be thoroughly cleaned and sanitized if potable water is involved, which many firefighting tanks are not designed for. Furthermore, weight distribution and road authority permits still apply. It is primarily built as a fire tanker, and any alternative use must be carefully evaluated for safety and legality.

Q: What’s the most common failure point on older tankers?

A: Beyond general chassis wear, two areas demand attention: 1) Pump Seals and Valves: Lack of regular exercise and lubrication causes seals to dry-rot and valves to seize. 2) Tank Support Structure and Plumbing: Constant stress from water surge can fatigue metal supports and loosen plumbing connections, leading to leaks.

Final Checklist Before You Buy

To secure a 3000 gallon fire tanker for sale that won’t let you down, use this final checklist:

- Review complete service and repair history for the chassis and pump.

- Obtain recent pump certification and tank integrity test reports.

- Conduct a hands-on, full operational test of all systems, including pumping at rated capacity.

- Have a trusted, independent mechanic specializing in heavy trucks perform a chassis inspection.

- Verify the title status and ensure there are no liens on the vehicle.

- Confirm availability of operational manuals and wiring diagrams.

Investing time in due diligence is the surest path to acquiring a fire apparatus that is genuinely reliable & ready for duty, safeguarding your community and your budget for years to come.

Sources & Further Reading:

1. National Fire Protection Association (NFPA). NFPA 1911: Standard for the Inspection, Maintenance, Testing, and Retirement of In-Service Emergency Vehicles. 2022 Edition. https://www.nfpa.org/1911

2. U.S. Fire Administration. Apparatus Purchasing Guide. FA-314, May 2019. https://www.usfa.fema.gov/publications/fa-314