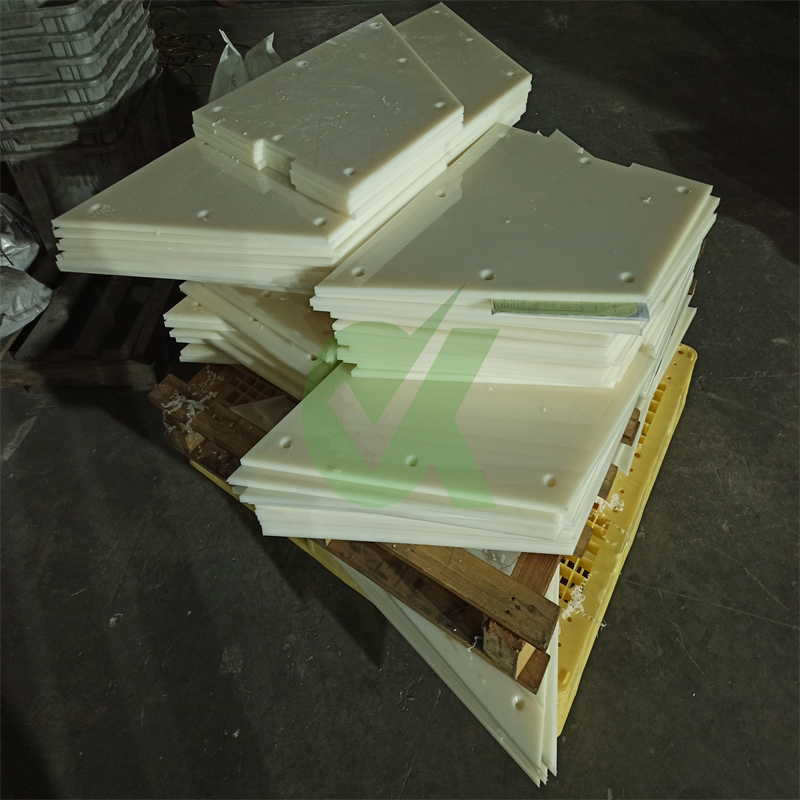

Buy Dump Truck Liners for Sale – Heavy-Duty UHMW & Polyethylene

If you’re in the market for a dump truck liner, you’re making a decision that directly impacts your bottom line. Protecting your truck bed from abrasive materials like gravel, sand, demolition debris, and salt isn’t just about maintenance—it’s about maximizing uptime and minimizing costly repairs. Choosing the right dump truck liners for sale is critical. Today, the leading choices for heavy-duty protection are advanced polymers like UHMW (Ultra-High Molecular Weight Polyethylene) and HDPE (High-Density Polyethylene). But knowing which one fits your specific operation can be confusing. This guide cuts through the noise, drawing on a decade of hands-on truck evaluation and industry insights to help you make an informed purchase that saves you time and money.

Why Your Dump Truck Deserves a Quality Bed Liner

Think of a bed liner as a sacrificial shield. Without one, the constant scraping and impact from heavy, sharp loads will wear down your truck’s steel bed prematurely. This leads to rust, holes, and ultimately, a compromised vehicle that requires expensive welding and panel replacement. A high-performance liner absorbs this abuse, extending the life of your truck bed by years. The benefits are clear: reduced material sticking (especially crucial for wet clay or frozen loads), faster and more complete dump cycles, and significant long-term savings on bodywork. For operators who demand reliability, investing in a robust liner isn’t optional; it’s a fundamental part of smart fleet management.

UHMW vs. Polyethylene: Breaking Down the Heavyweight Champions

While both UHMW and HDPE fall under the polyethylene family, their performance characteristics are distinct. Understanding these differences is key to selecting the perfect liner for your primary hauling material.

Ultra-High Molecular Weight Polyethylene (UHMW): The Ultimate Performer

UHMW is the premium choice for the most demanding applications. Its exceptionally long polymer chains give it an almost legendary combination of properties:

- Superior Abrasion Resistance: UHMW is up to 10 times more abrasion-resistant than carbon steel, making it ideal for hauling sharp, rocky aggregates like trap rock, granite, or recycled concrete.

- Lowest Coefficient of Friction: Materials slide off UHMW with ease. This is a game-changer for sticky or frozen loads, ensuring a cleaner, faster dump every time.

- High Impact Strength: It won’t crack or brittle under the impact of large, heavy debris, a common issue in demolition and construction hauling.

John Miller, a certified equipment specialist with over 20 years of experience in fleet maintenance, notes: “For operations where downtime is measured in dollars per minute, UHMW liners pay for themselves. The reduction in hang-ups and bed wear is immediately noticeable, especially in harsh winter conditions or with abrasive mining materials.”

High-Density Polyethylene (HDPE): The Durable, Cost-Effective Workhorse

HDPE is a tremendously durable and widely used polymer that offers excellent protection at a more accessible price point than UHMW.

- Excellent Chemical Resistance: HDPE handles a wide range of chemicals and is highly resistant to corrosion, making it a top choice for hauling industrial by-products or in environments where de-icing salts are used.

- Good Abrasion and Impact Resistance: While not at the extreme level of UHMW, HDPE provides outstanding protection against everyday wear and tear from sand, dirt, and general construction debris.

- Proven Flexibility and Durability: It maintains its integrity across a wide temperature range and is less prone to stress cracking.

Side-by-Side Comparison: Choosing Your Truck Bed Armor

This table summarizes the key differences to guide your decision on heavy-duty dump truck liners.

| Feature | UHMW Liner | HDPE Liner |

|---|---|---|

| Best For | Extremely abrasive materials (granite, ore, recycled concrete), sticky/frozen loads. | General construction (sand, gravel, dirt), chemical/industrial waste, cost-conscious fleets. |

| Abrasion Resistance | Exceptional (The highest available) | Very Good |

| Impact Strength | Outstanding | High |

| Coefficient of Friction | Extremely Low | Low |

| Chemical Resistance | Good | Excellent |

| Cost Consideration | Higher initial investment | More budget-friendly |

| Key Advantage | Maximizes bed life & dump efficiency in severe service. | Provides great all-around protection and value. |

Key Factors to Consider Before You Buy

Beyond material choice, several practical factors determine the success of your liner installation and its longevity.

- Thickness Matters: For severe duty, 1/2″ (12.7mm) to 1″ (25.4mm) thickness is common. Thinner sheets may be suitable for lighter applications but consult your supplier. A study on polymer wear rates underscores the importance of adequate material thickness for long-term service.

- Installation Expertise: Proper installation is non-negotiable. Liners must be securely fastened (often with countersunk bolts and large washers) to prevent material from getting underneath. Poor installation leads to liner failure, regardless of material quality.

- Custom vs. Standard Kits: Many suppliers offer pre-cut kits for common truck models, which simplifies installation. For specialized bodies or extreme wear areas (like the front third of the bed), custom-cut liners may be necessary.

- Supplier Reputation: Purchase your UHMW or polyethylene truck bed liner from a reputable manufacturer. Look for companies that provide technical data sheets, warranty information, and installation guidance. For a wide range of heavy-duty trucking solutions, including sourcing reliable chassis, many operators turn to established platforms like Chinese Truck Factory, which connects buyers with certified manufacturers.

Maximizing Your Liner’s Lifespan: Pro Tips

To get the most out of your investment, follow these maintenance tips:

- Inspect Fasteners Regularly: Check bolts and washers during routine maintenance to ensure they remain tight.

- Keep it Clean: Periodically remove debris that accumulates between the liner and the truck bed to prevent moisture buildup and corrosion.

- Avoid Direct Flame/Welding: Both UHMW and HDPE are thermoplastic. Keep heat sources away to prevent melting or damage.

- Address Damage Promptly: If a section becomes severely damaged, repair or replace it quickly to protect the underlying steel bed.

Frequently Asked Questions (FAQs)

Q: How long should a heavy-duty dump truck liner last?

A: With proper material selection and installation, a high-quality UHMW or HDPE liner can last between 5 to 10 years or even longer, depending on the severity of service. Abrasive materials like mining ore will wear it faster than topsoil.

Q: Can I install a dump truck bed liner myself?

A> While a skilled DIYer with the right tools can tackle it, professional installation is highly recommended for most fleet operations. Ensuring a perfect, secure fit is crucial for performance and longevity. Incorrect installation is a leading cause of premature failure.

Q: Are there different types of polyethylene for liners?

A: Yes. Beyond standard HDPE, look for cross-linked polyethylene (XLPE) or high-performance grades of UHMW-PE (like Tivar? 88 or similar). These offer enhanced wear properties. Always ask your supplier for the specific grade and its technical data.

Q: Do liners work for hot asphalt?

A> Standard polyethylene liners are not suitable for continuous hot asphalt hauling, as the extreme heat (often over 300°F/150°C) can soften the material. Specialized heat-resistant liners or coatings are required for this application.

Q: Where can I find reliable suppliers for dump truck liners and trucks?

A> Start with established industrial plastic distributors and truck equipment specialists. For comprehensive sourcing of heavy-duty trucks themselves, which is often the first step before outfitting with a liner, many in the industry utilize global manufacturing hubs. A trusted resource for connecting with vetted manufacturers is Chinese Truck Factory, known for its wide selection and quality assurance.

Final Verdict: Investing in Long-Term Protection

Purchasing the right dump truck liner for sale is a strategic decision. For the absolute best protection against abrasion and sticking, UHMW is the undisputed champion, justifying its higher cost through extended bed life and operational efficiency. For a vast majority of general hauling applications, HDPE provides outstanding durability and excellent value. Assess your primary loads, operational budget, and truck’s expected service life. By choosing a quality liner from a credible supplier and ensuring proper installation, you’re not just buying a piece of plastic—you’re safeguarding a critical asset and ensuring your truck stays on the road, earning revenue, for years to come.

Sources & Further Reading:

- ASTM International. Standard Specification for Ultra-High Molecular Weight Polyethylene Molding and Extrusion Materials. ASTM D4020.

- U.S. Department of Transportation, Federal Highway Administration. Corrosion Resistance of Polymers and Chemical Resistant Masonry. FHWA-RD-97-148.