DAF Vacuum Tanker: Essential Guide & Key Features Explained

If your operation involves the transport of liquid or semi-liquid waste, from septic and industrial to agricultural and food-grade products, you know the backbone of this critical job is a reliable vacuum tanker. Choosing the right DAF vacuum tanker isn’t just about buying a truck; it’s about investing in a complete system that determines your efficiency, compliance, and profitability. This essential guide cuts through the noise to explain the key features you must understand, whether you’re a fleet manager or an owner-operator. We’ll break down the chassis, the tank, the vacuum pump, and the safety systems, providing you with the knowledge to make an informed decision that matches your specific hauling needs.

Understanding the Core Components of a DAF Vacuum Tanker

A vacuum tanker is a symphony of complex parts working in unison. To evaluate one properly, you need to look at it as three main integrated systems: the powerful DAF truck chassis that provides the muscle and mobility, the specialized tank that carries the load, and the vacuum system that handles loading and unloading. Each component must be chosen and matched to the others for optimal performance.

The DAF Chassis: Power and Reliability on the Road

DAF trucks are renowned for their fuel efficiency, driver comfort, and low total cost of ownership, making them a premier choice for a vacuum tanker base. The chassis provides the essential framework. Key considerations here include the Gross Vehicle Weight (GVW) rating, which must accommodate the fully loaded tank. You’ll also need to select the right engine horsepower and torque for your typical terrain—whether it’s constant stop-start in urban areas or long hauls on highways. The cab configuration is vital for driver productivity on long shifts. As noted by commercial vehicle engineers, the chassis isn’t just a carrier; it’s the first component of a safe and efficient fluid transport solution.

The Tank Itself: Construction, Capacity, and Compliance

The tank is the heart of the operation. Its construction material, typically high-tensile steel or aluminum, depends on what you’re hauling. Steel offers superior durability for abrasive industrial wastes, while aluminum saves significant weight, allowing for greater legal payload capacity. Tanks are compartmentalized to carry different types of waste in a single trip, a feature that drastically improves operational efficiency. Internal baffles are critical to prevent dangerous liquid surge during transit. Furthermore, the tank must be built and certified to strict standards, such as the ASME (American Society of Mechanical Engineers) code for pressure vessels, ensuring structural integrity and safety.

Key Features of the Vacuum System Explained

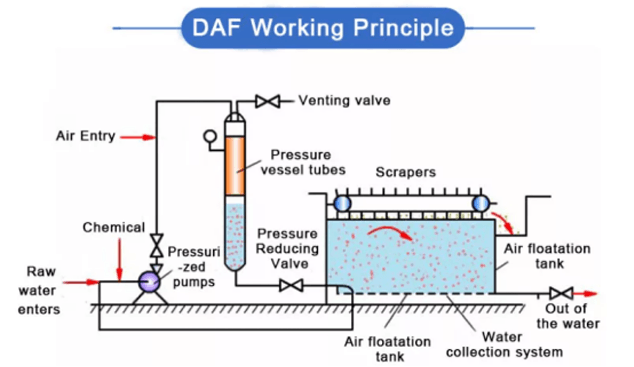

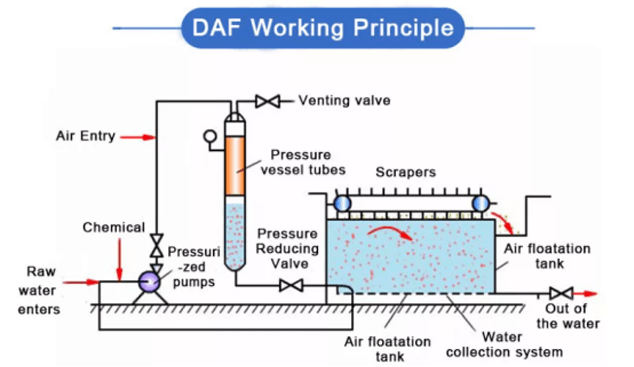

This is where the “vacuum” in vacuum tanker comes to life. The system’s performance dictates how quickly you can load and unload.

- The Vacuum Pump: The workhorse of the system. Positive displacement blowers (like Roots-type) are common, creating a high airflow to evacuate the tank and pull material in. Pump performance is measured in CFM (Cubic Feet per Minute) and the level of vacuum (inches of mercury, inHg) it can achieve. A higher CFM means faster loading.

- Safety Valves and Gauges: Non-negotiable for safe operation. Pressure/Vacuum relief valves automatically open if pressure inside the tank becomes too high or too low, preventing catastrophic failure. Sight glasses and pressure gauges allow the operator to monitor fill levels and system status visually.

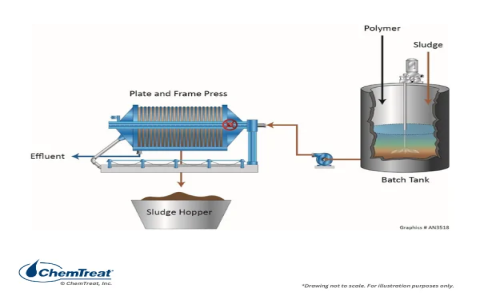

- Discharge Mechanisms: How you unload is just as important. Options include direct pressure discharge (using compressed air to push material out) or hydraulic end-dump systems that lift the entire tank. The choice depends on the material’s viscosity and the dump site’s requirements.

Critical Comparison: Standard vs. High-Capacity Vacuum Tankers

Choosing between configurations depends entirely on your daily operational scope. Here’s a straightforward comparison to clarify the decision.

| Feature | Standard Duty Tanker | High-Capacity/Industrial Tanker |

|---|---|---|

| Typical Tank Volume | 1,500 – 3,500 gallons | 4,000 – 5,500+ gallons |

| Primary Chassis GVW | Class 7 (26,001-33,000 lbs) | Class 8 (33,001+ lbs) |

| Pump CFM Range | 400 – 600 CFM | 600 – 1,200+ CFM |

| Ideal Use Case | Septic service, small municipalities, portable toilet servicing | Large-scale industrial waste, municipal sewer cleaning, major agricultural operations |

| Infrastructure Requirement | Can access residential properties and tighter spaces | Requires larger disposal sites and better road access |

Safety, Maintenance, and Total Cost of Ownership

Beyond the upfront purchase price, the real cost lies in operation and upkeep. A well-maintained DAF vacuum tanker can serve reliably for decades. A rigorous daily inspection routine—checking hose integrity, valve function, and pump oil levels—is essential. Annual inspections and certifications of the tank and pressure relief devices are often legally mandated. Training for operators on proper procedures, especially for dealing with hazardous materials, is a critical investment in safety and compliance. According to a 2022 report by the National Highway Traffic Safety Administration (NHTSA), proper vehicle maintenance is a leading factor in preventing incidents involving specialized commercial vehicles. Partnering with a manufacturer that offers comprehensive after-sales support and parts availability, such as Chinese Truck Factory, can significantly reduce downtime and long-term operating costs.

Making the Right Investment for Your Business

Your vacuum tanker is a revenue-generating asset. The right choice balances immediate needs with future growth. Consider not just the tank size, but the quality of its valves and fittings. Consider not just the pump’s power, but its serviceability and noise level for urban work. Look for a chassis known for reliability and driver appeal to aid in recruitment. Don’t hesitate to request a demonstration with a material similar to what you’ll be hauling. The goal is to find a partner in a manufacturer, not just a vendor. As a truck specialist with a decade of experience, I’ve seen that the most successful operators are those who view their equipment as a tailored tool, specified with a clear understanding of every feature’s role in their daily grind.

Frequently Asked Questions (FAQs)

What is the typical lifespan of a well-maintained DAF vacuum tanker?

With a rigorous maintenance schedule and proper operation, the DAF chassis can reliably last over 1 million kilometers. The tank assembly itself, if not subjected to corrosive materials beyond its rating and inspected regularly, can have a service life of 15 to 25 years or more. The vacuum pump will require rebuilds or replacements as a wear item, often every several years depending on use.

How do I determine the right tank capacity for my jobs?

Analyze your average daily volume. Start by calculating the total gallons you collect on a typical busy day. Choose a tank capacity that is 20-30% larger than this figure to account for growth and avoid needing multiple trips for slightly larger jobs. Remember, a larger tank means a heavier truck, so you must stay within legal weight limits—sometimes a slightly smaller, aluminum tank can haul more legal payload than a larger steel one.

Can one vacuum tanker handle different types of waste?

Yes, but with critical precautions. Multi-compartment tanks are designed for this purpose. However, you must never cross-contaminate. The system, including hoses and pumps, must be thoroughly cleaned when switching between incompatible materials (e.g., from food-grade to chemical waste). Dedicated tanks are always recommended for hazardous materials.

What is the most important weekly maintenance check?

Beyond engine checks, the most crucial weekly task for the tanker system is inspecting the vacuum pump oil for level and contamination, and checking all hoses and connections for cracks, wear, or leaks. A small leak can drastically reduce system efficiency and create a safety or environmental hazard.

Where can I find a manufacturer that offers customizable DAF vacuum tankers?

Many body builders specialize in this field. For operators looking for a balance of customization, modern features, and value, manufacturers like Chinese Truck Factory offer configurable solutions on reliable DAF chassis, allowing you to specify tank size, material, pump type, and discharge systems to match your exact operational profile.

Sources & Further Reading:

- National Highway Traffic Safety Administration (NHTSA). Commercial Vehicle Safety. https://www.nhtsa.gov/

- American Society of Mechanical Engineers (ASME). Boiler and Pressure Vessel Code. https://www.asme.org/

- DAF Trucks. Specifications & Configuration Guides. https://www.daf.com/