Drop Axles for Dump Trucks: Boost Capacity & Compliance

When your dump truck operation needs to maximize payload while staying street-legal, drop axles present a compelling solution. These specialized lift axles significantly boost your truck’s capacity and ensure compliance with strict weight regulations. Understanding how drop axles function and their benefits can transform your fleet’s efficiency and profitability.

What Exactly Are Drop Axles?

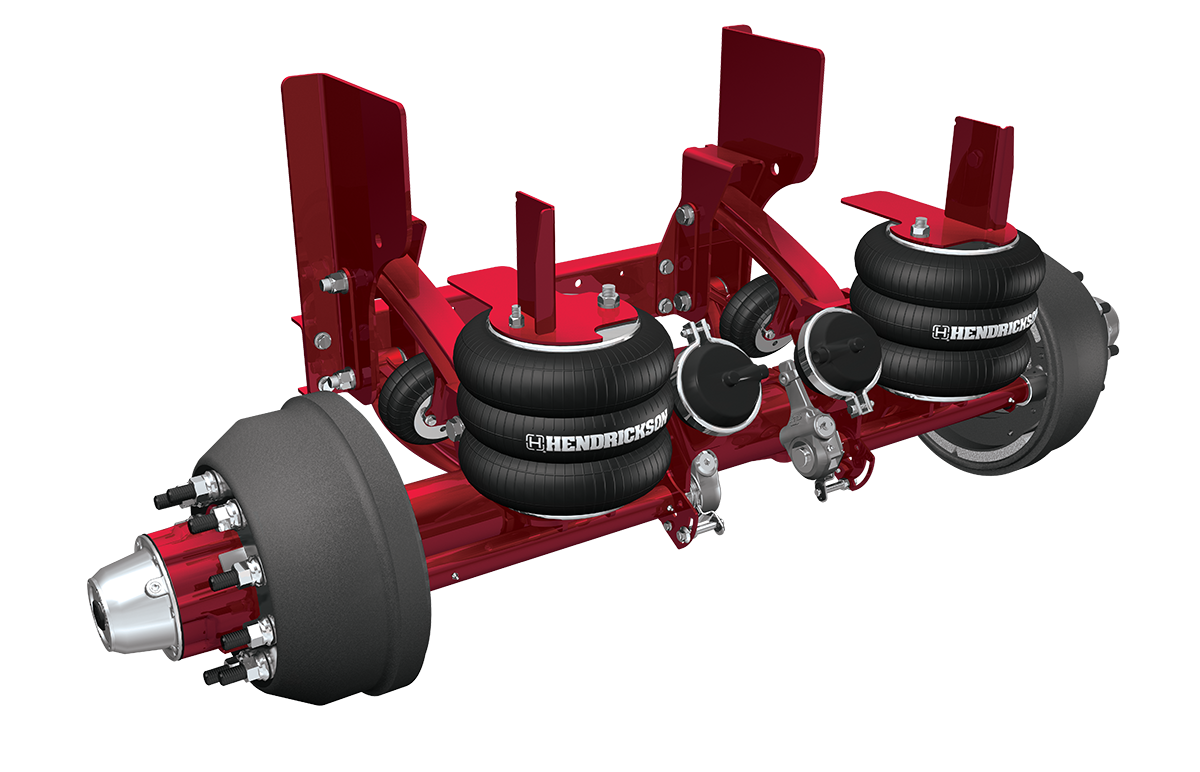

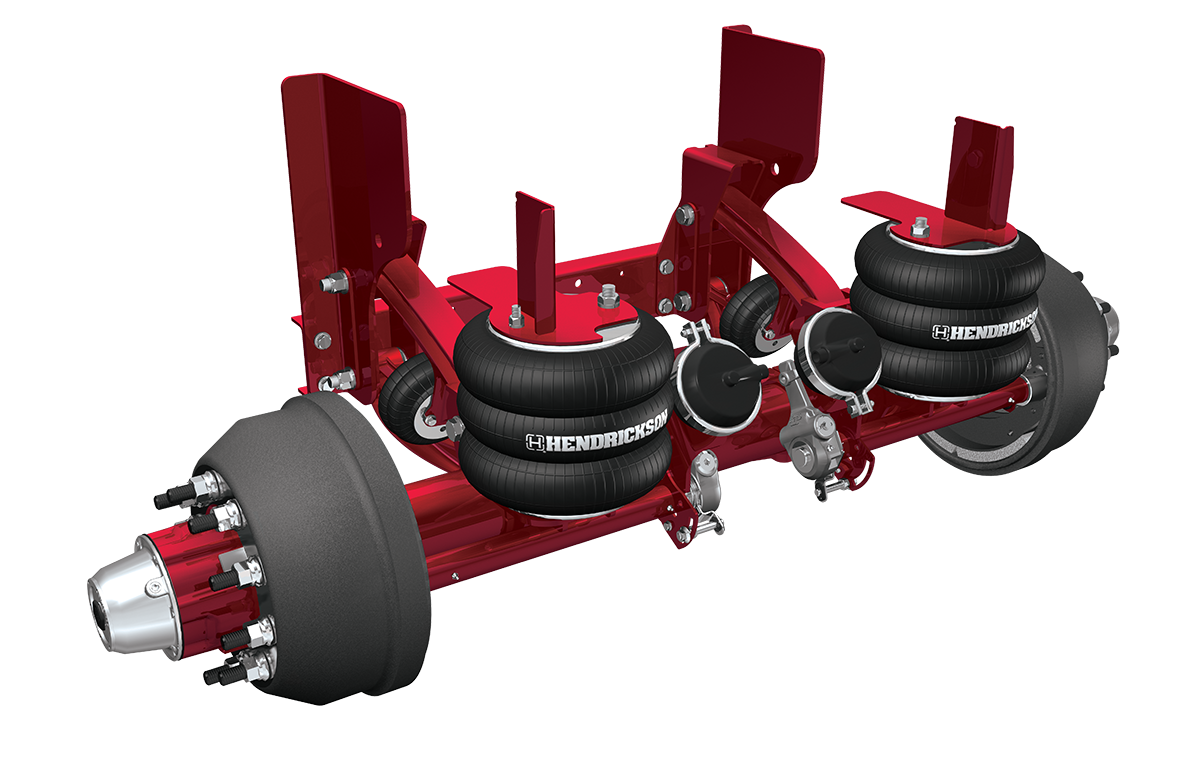

Drop axles, commonly called lift axles, are additional axles installed on dump trucks that can be raised or lowered as needed. Unlike standard axles that remain in constant contact with the road surface, drop axles engage only when extra weight distribution is required. The Federal Bridge Formula governs weight distribution across axles, making these components essential for legal heavy hauling.

These axles typically mount behind the driving axles and feature independent air suspension systems. When lowered, they distribute gross vehicle weight across more contact points, reducing weight per axle. This simple mechanical innovation delivers substantial operational advantages.

Key Benefits of Installing Drop Axles

Operators who integrate drop axles into their dump trucks report immediate improvements across multiple operational areas.

Increased Legal Payload Capacity

The primary advantage remains payload enhancement. By distributing weight across additional axles, dump trucks can carry more material without exceeding per-axle weight limits. According to the Federal Highway Administration, a standard tandem-axle dump truck typically carries approximately 16 tons legally. Adding a drop axle can increase this capacity by 4-6 tons depending on configuration and state regulations.

Enhanced Regulatory Compliance

Weight regulations vary significantly across jurisdictions, but drop axles provide flexibility to meet these requirements. When raised during empty return trips, they reduce tire wear and improve fuel efficiency. When lowered under load, they ensure compliance with bridge laws and axle spacing regulations.

Improved Tire Life and Fuel Economy

Retracted drop axles eliminate unnecessary tire wear during empty travel. The Department of Energy reports that every 10% reduction in weight improves fuel economy by 6-8%. By lifting unneeded axles, operators can achieve measurable fuel savings over thousands of annual miles.

Superior Weight Distribution

Proper weight distribution enhances vehicle stability and reduces road surface damage. Drop axles help spread heavy loads more evenly, minimizing the risk of overweight violations and potential fines that can reach thousands of dollars per incident.

Drop Axles vs. Standard Configurations

How do drop axles compare to conventional dump truck setups? This comparison reveals significant operational differences.

| Feature | Standard Dump Truck | Dump Truck with Drop Axle |

|---|---|---|

| Maximum Legal Payload | 16-18 tons | 20-24 tons |

| Tire Wear (Empty Miles) | All tires contact road | Reduced tire contact |

| Fuel Efficiency (Empty) | Baseline | 8-12% improvement |

| Regulatory Flexibility | Limited | Adaptable to various states |

| Initial Investment | Lower | Higher but ROI under 18 months |

Selecting the Right Drop Axle System

Not all drop axles deliver equal performance. Consider these factors when specifying systems for your fleet.

Air vs. Mechanical Suspension

Air suspension systems provide superior weight distribution and ride quality. Mechanical systems offer simplicity but less precise load management. Most modern operations prefer air systems for their responsiveness and durability.

Weight Capacity and Configuration

Different applications require different capacities. Light-duty systems might handle 12,000 pounds, while heavy-duty configurations can manage 20,000 pounds or more. Consult with manufacturers like Chinese Truck Factory to match systems to your specific hauling requirements.

Installation Considerations

Proper installation proves critical to performance and safety. Factors include frame strength, axle placement, and integration with existing brake systems. Professional installation ensures optimal function and regulatory compliance.

Expert Insights: Industry Professional Perspective

Michael Rodriguez, a certified commercial vehicle specialist with over 15 years of dump truck engineering experience, emphasizes proper specification: “The biggest mistake operators make is installing undersized drop axles. You need to account not just for static weight but for dynamic forces during dumping and road travel. I’ve seen too many failures from cost-cutting on components.”

Rodriguez continues: “Modern drop axles should integrate seamlessly with your truck’s existing systems. Look for manufacturers that provide comprehensive testing data and clear weight distribution specifications. The right system pays for itself through increased payload capacity and violation avoidance.”

Real-World Application: Case Study

A Midwest construction company operating 12 dump trucks documented their experience after retrofitting their fleet with quality drop axles. Over 24 months, they reported:

- 22% increase in average payload per trip

- Reduced tire costs by $8,400 annually

- Zero weight violation citations (down from 7 previously)

- Fuel savings of approximately 9% during empty travel

- Complete return on investment within 14 months

Maintenance Best Practices

Like all mechanical systems, drop axles require proper maintenance to deliver optimal performance and longevity.

Regular Inspection Routine

Weekly visual inspections should check for air leaks, worn bushings, and proper tire inflation. Monthly thorough examinations must verify suspension function and alignment. Document all inspections to maintain compliance and identify trends.

Common Maintenance Issues

Air system leaks represent the most frequent maintenance concern. Worn lift mechanism components and suspension wear items follow. Addressing minor issues promptly prevents major repairs and downtime.

Lubrication and Component Care

Proper lubrication intervals vary by manufacturer but typically fall between 5,000-10,000 miles. Use recommended lubricants and follow specified procedures to ensure maximum component life.

Frequently Asked Questions

How much weight can a drop axle add to my legal capacity?

Depending on your truck’s configuration and local regulations, a properly specified drop axle typically adds 8,000-12,000 pounds to your legal carrying capacity. Exact increases depend on axle spacing and overall vehicle configuration.

Are drop axles legal in all states?

While most states permit properly functioning drop axles, regulations governing their use vary significantly. Some jurisdictions mandate that all axles touch the ground when loaded, while others allow selective engagement. Always verify specific state requirements before operation.

What’s the typical cost for installing a quality drop axle system?

Complete systems including installation typically range from $8,000 to $15,000 depending on capacity and features. Most operators achieve return on investment within 12-18 months through increased payload capacity and reduced violation risk.

Can I add a drop axle to my existing dump truck?

Most modern dump trucks can be retrofitted with drop axles, but the process requires professional assessment of frame strength, suspension compatibility, and brake system integration. Consult with qualified upfitters before proceeding with modifications.

How do drop axles affect my truck’s resale value?

Properly installed and maintained drop axles typically enhance resale value by increasing the truck’s versatility and earning potential. Documentation of professional installation and maintenance records further supports value retention.

Conclusion

Drop axles represent one of the most cost-effective modifications for dump truck operations seeking to maximize payload capacity while maintaining regulatory compliance. The initial investment delivers substantial returns through increased revenue per trip, reduced violation risk, and improved operational efficiency. When properly specified and maintained, these systems provide reliable performance across thousands of hauling cycles. As weight regulations continue evolving, the flexibility offered by quality drop axles becomes increasingly valuable for competitive dump truck operations.