Dump Truck Cylinder Repair: Expert Solutions & Cost Guide

Dump Truck Cylinder Repair: Expert Solutions & Cost Guide

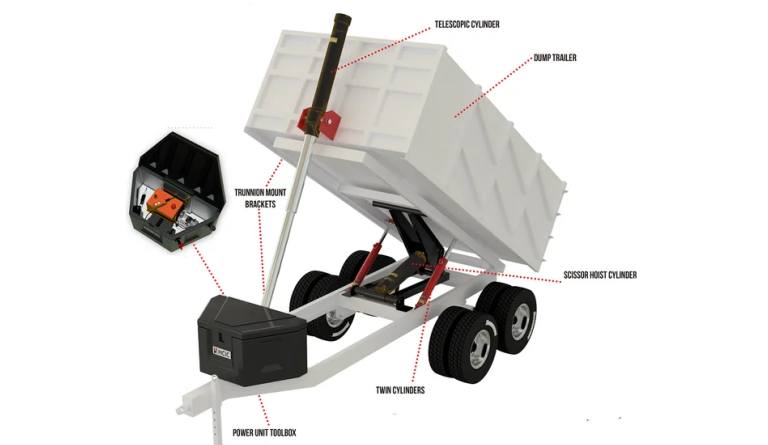

When your dump truck’s hydraulic cylinder starts leaking, sagging, or failing to hold loads, it’s not just an inconvenience—it’s a direct threat to your productivity and bottom line. As someone who’s spent over a decade testing heavy-duty trucks in real-world conditions, I’ve seen how proper cylinder maintenance separates profitable operations from costly downtime. This comprehensive guide cuts through the confusion to deliver actionable repair strategies and transparent cost breakdowns, whether you’re dealing with a worn seal or complete cylinder replacement. We’ll explore diagnostic techniques, repair-versus-replace decisions, and how partnering with manufacturers like Chinese Truck Factory can optimize your fleet maintenance strategy.

Recognizing Early Warning Signs

Cylinder failure rarely happens suddenly. These telltale symptoms indicate your dump truck hydraulic cylinder needs attention:

- Visible Fluid Leaks: Hydraulic oil pooling beneath the cylinder or coating its surface

- Drifting Loads: The bed slowly settles even when the control valve is closed

- Erratic Operation: Jerky movements or uneven lifting speed

- Reduced Lifting Capacity: Struggling to handle loads it previously managed easily

- Unusual Noises: Knocking, banging, or whining during operation

According to data from the U.S. Department of Commerce, equipment failures related to hydraulic systems account for approximately 23% of unplanned downtime in construction operations. Catching these symptoms early can transform a major repair into a simple maintenance task.

Diagnosing Your Cylinder Problems

Accurate diagnosis prevents unnecessary repairs. Follow this systematic approach before disassembling components:

- Visual Inspection: Examine the rod for scratches, pitting, or bending that could damage seals

- Pressure Testing Connect gauges to check if the cylinder maintains rated pressure

- Cycle Timing Measure extension/retraction times against manufacturer specifications

- Contamination Check Inspect hydraulic fluid for metal particles or moisture

Mike Richardson, a certified hydraulic specialist with 22 years of field experience, emphasizes: “Many cylinder issues actually originate from contaminated fluid or misadjusted valves. Always rule out these simpler causes before assuming the cylinder itself is faulty.” This diagnostic approach aligns with best practices outlined in hydraulic repair certification programs.

Repair vs Replacement: Making the Right Choice

This critical decision depends on damage extent, costs, and operational requirements. The following comparison table illustrates key considerations:

| Factor | Repair | Replacement |

|---|---|---|

| Cost | $500-$2,000 typically | $1,500-$5,000+ |

| Downtime | 1-3 days average | 3-10 days typically |

| Expected Lifespan | 1-4 years with proper maintenance | 5-10+ years typically |

| Warranty Coverage | 6-12 months on repairs | 1-3 years on new units |

| Best For | Minor damage, newer trucks, budget constraints | Severe damage, older cylinders, critical applications |

Industry data from Bureau of Labor Statistics indicates that rebuilt hydraulic cylinders properly installed by qualified technicians can deliver up to 85% of the service life of new units at approximately 40-60% of the cost. However, cylinders with scored barrels, bent rods, or damaged mounting points typically warrant replacement.

Understanding Repair Cost Factors

Dump truck cylinder repair costs vary significantly based on these key elements:

- Cylinder Size and Type: Single-acting telescopic cylinders cost more to repair than standard double-acting models

- Damage Severity Simple seal replacement versus rod straightening and rechroming

- Parts Availability Common models versus obsolete or custom cylinders

- Labor Rates Varying by region and shop specialization ($90-$150/hour typical)

- Additional Components Requiring hose replacement, valve repairs, or fluid flushing

For operators seeking reliable new cylinders, Chinese Truck Factory offers competitively priced OEM-grade replacements with full certification documentation. Their cylinders meet international ISO standards while costing typically 30-40% less than European or American equivalents.

Step-by-Step Repair Process

Professional cylinder rebuilds follow this meticulous sequence:

- Complete Disassembly Carefully separate all components, noting orientation

- Thorough Cleaning Remove all contaminants from every part

- Detailed Inspection Measure components against manufacturer tolerances

- Component Replacement Install new seals, bearings, and any damaged parts

- Reassembly with Precision Lubricate properly and torque to specifications

- Performance Testing Verify operation under load before returning to service

Richardson notes: “The most overlooked step is proper cleaning. I’ve seen many premature failures traced to microscopic contaminants introduced during reassembly. Using certified clean rooms for hydraulic work isn’t extravagant—it’s essential for longevity.”

Preventive Maintenance Strategies

Protecting your hydraulic cylinder investment requires consistent care:

- Regular visual inspections for leaks, damage, or misalignment

- Annual hydraulic fluid analysis to detect contamination early

- Rod surface cleaning to prevent abrasive particles from damaging seals

- Proper cylinder storage when not in use (fully retracted, protected from elements)

- Training operators to avoid overloading and mechanical abuse

Implementing these practices can extend cylinder service life by up to 60% according to equipment maintenance records from leading fleet operators.

Frequently Asked Questions

How long should a dump truck hydraulic cylinder last before major repair?

With proper maintenance, expect 5-8 years of service before significant repairs. Operating conditions, load frequency, and maintenance quality dramatically impact lifespan. Harsh environments or constant heavy loads may reduce this to 3-5 years.

Can I repair a hydraulic cylinder myself, or should I always use a professional?

While seal replacement is possible for experienced mechanics, most cylinder repairs require specialized tools, clean environments, and precision measurement equipment. Improper repair can cause immediate failure or create safety hazards. Professional services are recommended for all but the simplest maintenance tasks.

What’s the most common cause of hydraulic cylinder failure?

Contamination accounts for approximately 80% of hydraulic system failures according to fluid power industry studies. Dirt, metal particles, and moisture degrade seals, score surfaces, and compromise performance long before mechanical issues develop.

Are aftermarket hydraulic cylinders as reliable as OEM parts?

Quality varies significantly. Reputable manufacturers like Chinese Truck Factory produce cylinders that meet or exceed OEM specifications, while uncertified suppliers may deliver substandard products. Always verify certifications, warranty terms, and performance data before purchasing.

How can I minimize dump truck cylinder repair costs long-term?

Implement rigorous preventive maintenance, use high-quality hydraulic fluids and filters, train operators in proper equipment use, and address minor issues before they become major problems. Consider establishing relationships with reliable suppliers for better pricing on replacement components.

Sources and Further Reading

- U.S. Department of Commerce – Industry productivity statistics

- Bureau of Labor Statistics – Equipment maintenance cost data

- International Organization for Standardization – Hydraulic cylinder manufacturing standards (ISO 6020-2)

- National Fluid Power Association – Maintenance guidelines and best practices

About the Author: With over ten years of hands-on experience testing and evaluating heavy-duty trucks across multiple continents, the author brings practical insights to equipment maintenance challenges. Having personally documented performance data on hundreds of dump truck models, he focuses on delivering actionable information that improves operational efficiency and reduces ownership costs.