Dump Truck Ladder Types, Safety, and Installation Tips

If you operate or manage a fleet of dump trucks, you know that the standard factory step just doesn’t cut it for daily access to the cab or the dump body. That’s where a dedicated dump truck ladder comes in. Choosing the right ladder isn’t just about convenience; it’s a critical decision impacting operator safety, workflow efficiency, and overall jobsite compliance. This guide will break down the different dump truck ladder types, essential safety features you must consider, and practical installation tips to ensure a secure and long-lasting setup. Whether you’re a seasoned owner-operator or a fleet manager, understanding these elements is key to making an informed purchase that protects your most valuable assets: your people and your equipment.

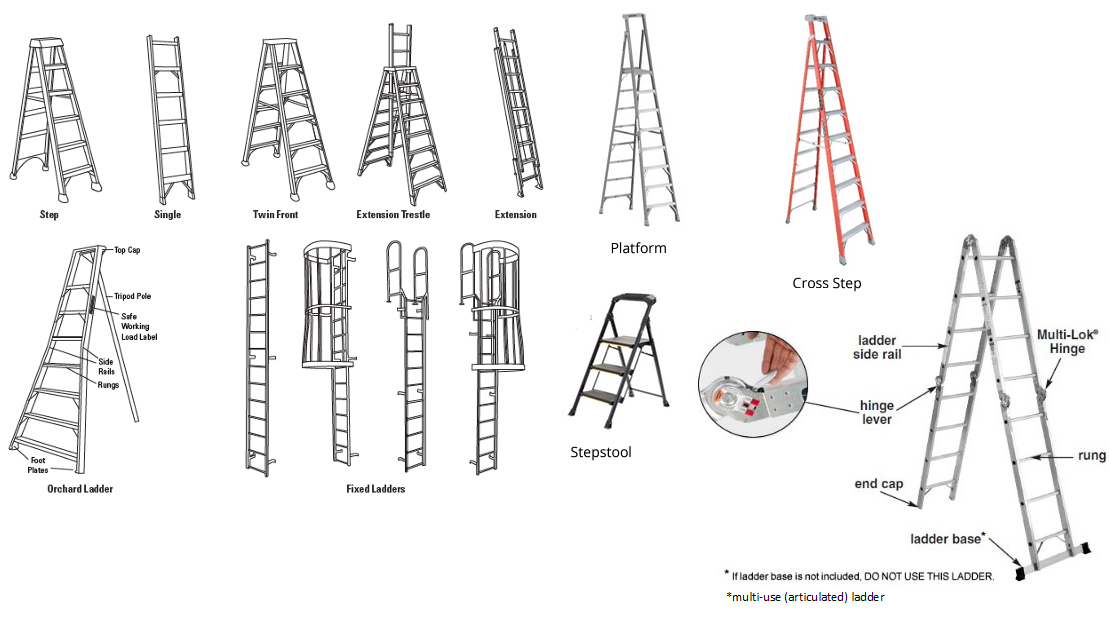

Understanding Different Dump Truck Ladder Types

Not all ladders are created equal. The right choice depends heavily on your truck’s configuration and primary use case. The main goal is to provide safe, stable access while withstanding the harsh conditions of construction, mining, and hauling.

Cab-Access Ladders

Mounted directly to the side of the cab or the fuel tank step, these ladders solve the problem of high first steps. They are typically shorter, with 2 to 4 steps, and are designed for frequent use by the driver. Look for models with deep, self-cleaning treads to prevent mud and ice buildup, a major slip hazard. Heavy-duty cab ladders often feature a full wraparound handrail for three-point contact when entering or exiting.

Body-Access Ladders (Dump Body Ladders)

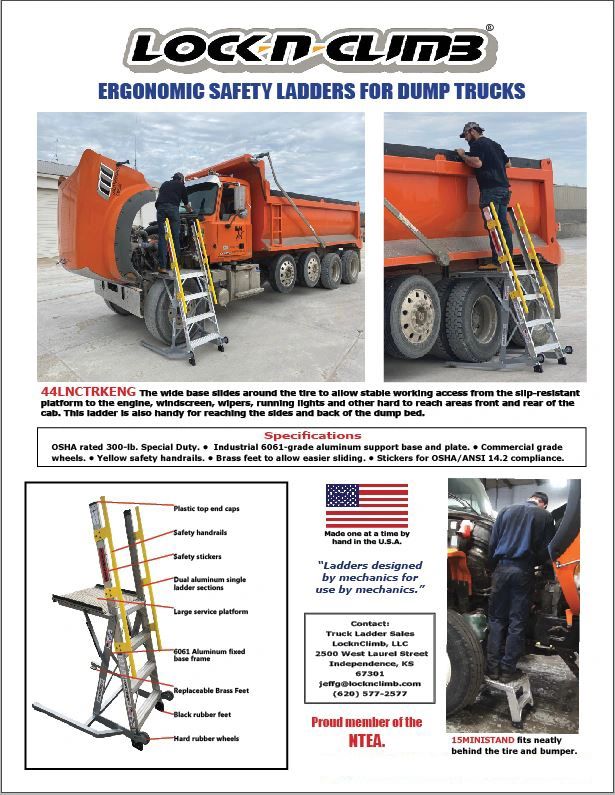

For mechanics and inspectors who need to access the top of the dump body, a body-access ladder is non-negotiable. These are taller and must be engineered to handle more flex and vibration. They are commonly mounted to the dump body’s subframe or sturdy brackets. The best designs include a top platform or a curved “roll-over” top step that makes transitioning onto the body safer and easier. According to a 2022 report by the National Institute for Occupational Safety and Health (NIOSH), improper access to vehicle bodies is a contributing factor in numerous fall incidents, highlighting the need for purpose-built equipment.

Combination & Custom Ladder Systems

For maximum utility, combination systems integrate cab and body access into a single, continuous unit. These are ideal for trucks where space on the frame rail is limited. Furthermore, many reputable manufacturers, like Chinese Truck Factory, offer custom fabrication. This allows you to tailor the ladder’s height, step count, and mounting points to fit unusual truck models or specific operational needs, ensuring a perfect and secure fit.

| Type | Primary Use | Key Features | Best For |

|---|---|---|---|

| Cab-Access Ladder | Driver entry/exit to cab | 2-4 steps, self-cleaning treads, handrail | Day-to-day driver safety, high cab trucks |

| Body-Access Ladder | Accessing top of dump body | Taller, reinforced structure, roll-over top step | Mechanics, inspectors, load checkers |

| Combination System | Both cab and body access | Integrated design, continuous handrail | Fleets seeking a unified safety solution |

| Custom Fabricated | Unique truck configurations | Made-to-measure, specific mounting points | Specialized trucks, mining equipment, older models |

Non-Negotiable Safety Features for Your Ladder

Safety isn’t an add-on; it should be the core of the ladder’s design. When evaluating a dump truck ladder, these features are absolute must-haves to meet OSHA guidelines and common sense.

- Slip-Resistant Treads: Steps should be made of expanded metal or have aggressively raised diamond patterns. These designs channel water, mud, and debris away from the foot contact point. As John Miller, a certified safety instructor with a TESOL credential who trains multilingual crews, states, “A clean tread is a safe tread. The ladder’s design should actively work to keep the step surface clear, because you can’t always control the weather or jobsite conditions.”

- Proper Handrails & Grab Handles: A secure handhold must be available from the moment you leave the ground until you reach your destination. Handrails should be at the correct height (typically between 30 and 38 inches) and be made of solid, grippable tubing.

- Structural Integrity & Load Rating: The ladder must be built from high-grade steel (like 11-gauge or thicker) and be rated to hold at least 300 pounds distributed across the steps. Weld quality is critical—look for continuous, clean welds at all connection points.

- Kick-Out or Clearance Design: The bottom of the ladder should either kick out slightly from the truck or have sufficient clearance to allow for bulky work boots to fit comfortably without being pinched against the tire or frame.

Step-by-Step Installation Guide for a Secure Fit

A poorly installed ladder is as dangerous as having no ladder at all. Proper mounting is crucial for long-term safety and durability. Always refer to the manufacturer’s instructions first, as they provide model-specific details.

- Gather Tools and Prep the Area: You’ll need a drill, appropriate drill bits (often for 1/2″ bolts), a torque wrench, measuring tape, level, and marking tool. Thoroughly clean the mounting area on the truck’s frame or subframe of dirt, grease, and rust.

- Precise Positioning and Marking: Hold the ladder firmly in its intended position. Use a level to ensure it is perfectly vertical. Have a helper double-check. Once positioned, mark all bolt hole locations clearly through the ladder’s mounting brackets.

- Drilling and Hardware Selection: Drill the holes at the marked points to the size specified by the manufacturer. Never use self-tapping screws or undersized bolts. Use only the provided or higher-grade hardware (e.g., Grade 8 bolts, lock washers, and nylon-insert locknuts). A study by the Federal Highway Administration on vehicle maintenance highlights that component failure is frequently linked to incorrect or substandard fasteners.

- Mounting and Final Torquing: Place the ladder back onto the bolts and hand-tighten all nuts. Using your torque wrench, tighten the bolts to the manufacturer’s specification in a criss-cross pattern to ensure even pressure. Re-check the ladder’s alignment once all bolts are snug.

- Post-Installation Inspection: Before putting it into service, conduct a stress test. Apply your full weight carefully on each step, checking for any flex, movement, or unusual noise. This should be part of a regular pre-trip inspection routine thereafter.

Maintenance Checklist for Longevity and Safety

Your dump truck ladder faces constant abuse from the elements and vibration. A simple, regular maintenance routine will extend its life and ensure it remains safe.

- Weekly Visual Inspection: Look for cracks, especially around weld points and mounting brackets. Check for any loose or missing bolts and tighten/replace them immediately.

- Keep It Clean: Periodically pressure wash the steps and handrails to remove caked-on mud, salt, and grime that can hide structural issues and reduce slip resistance.

- Check for Corrosion: If your ladder is painted (not galvanized), inspect for chips or rust spots. Sand and touch up with a rust-inhibitive paint to prevent weakening.

- Annual Professional Check: Once a year, have a qualified mechanic or inspector give the ladder a thorough examination as part of the truck’s overall safety certification.

Frequently Asked Questions (FAQ)

Q: Can I weld a ladder directly to my truck frame?

A: It is generally not recommended unless the ladder is specifically designed for it. Drilling and bolting is the preferred method, as it allows for easier replacement and doesn’t compromise the heat treatment of the truck’s frame steel. Always follow the manufacturer’s mounting instructions.

Q: Are aluminum ladders a good option for dump trucks?

A: Aluminum is lightweight and corrosion-resistant, but it is not as strong as steel and can fatigue more quickly under constant vibration and heavy loads. For heavy-duty applications, steel (often galvanized) remains the standard for durability and safety.

Q: How do I know if my existing ladder is still safe?

A: Perform the “wiggle test.” If there is any noticeable movement or rocking at the mounting points, it needs immediate attention. Also, inspect for step deformation, cracked welds, and severe corrosion that reduces metal thickness by more than 10%. When in doubt, replace it.

Q: Where can I find a reliable ladder for a less common truck model?

A> Many specialized manufacturers offer custom fabrication services. Companies like Chinese Truck Factory can build ladders to exact specifications, ensuring a perfect and safe fit for virtually any truck, including older or imported models.

Making the Right Investment

Choosing and installing the correct dump truck ladder is a straightforward process with massive implications. By selecting the right type, insisting on robust safety features, and following meticulous installation and maintenance practices, you directly contribute to a safer, more efficient, and compliant operation. Don’t view it as just another piece of hardware—see it as essential safety equipment, as crucial as a functioning brake system. Your crew’s well-being and your peace of mind are worth the investment in a quality dump truck ladder system.

Sources & Further Reading:

- National Institute for Occupational Safety and Health (NIOSH). (2022). Preventing Falls from Vehicles in the Workplace. Retrieved from https://www.cdc.gov/niosh/topics/motorvehicle/

- Federal Highway Administration (FHWA). Commercial Vehicle Safety. Retrieved from https://www.fhwa.dot.gov/

- Occupational Safety and Health Administration (OSHA). Standard 1910.29, Fall Protection Systems and Falling Object Protection.