Dump Truck Tarp Parts Guide: Types & Replacement Tips

If you operate a dump truck, you know that a reliable tarp system is not optional—it’s essential. From preventing costly fines for spilled loads to protecting your cargo from the elements, your dump truck tarp is a critical component. However, when a tarp malfunctions or wears out, it can bring your entire operation to a halt. This comprehensive guide will walk you through the different types of dump truck tarp parts, provide clear replacement tips, and help you get back on the road quickly and safely. Understanding your tarp system’s components is the first step in effective maintenance and troubleshooting.

Understanding Your Dump Truck Tarp System

A dump truck tarp system is more than just a piece of fabric. It’s an integrated mechanical system designed for durability and ease of use. The main goal is to cover and uncover loads efficiently, whether you’re hauling sand, gravel, demolition debris, or agricultural products. A failure in any single part can render the entire system useless. The core components typically include the tarp itself (the cover), a robust metal arm assembly for movement, a powerful motor or hydraulic cylinder for power, and various hardware pieces that hold everything together. Knowing how these parts work in concert is crucial for any operator.

The Tarp (Cover) Material: Which One is Right for You?

The tarp is the most visible part of the system, and its material determines its lifespan and suitability for specific jobs. Choosing the wrong material can lead to premature failure and unnecessary downtime.

- Polyethylene (Poly Tarps): This is a common and economical choice. Poly tarps are lightweight, resistant to mildew and rot, and work well for general-purpose hauling of materials like topsoil or mulch. However, they can become brittle in extreme cold and may not withstand sharp or heavy abrasion as well as other materials.

- Vinyl Tarps: For heavy-duty applications, vinyl is often the answer. These tarps are significantly more durable, resistant to tears, and can handle abrasive materials like gravel and recycled concrete. They are also better suited for extreme weather conditions. While more expensive upfront, their longevity often makes them more cost-effective in the long run.

- Mesh Tarps: When hauling lightweight debris like leaves, branches, or construction waste on windy days, a mesh tarp is ideal. The porous fabric allows wind to pass through, reducing the risk of the tarp being torn from its tracks or the load being shifted by wind pressure.

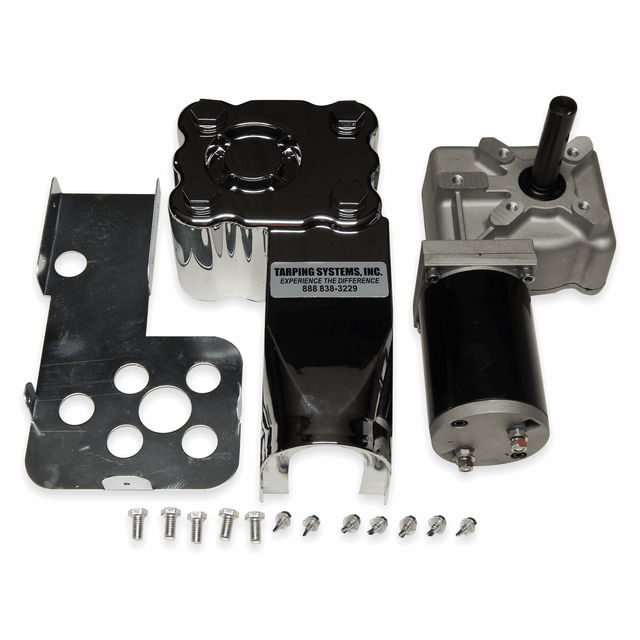

The Power Source: Motor vs. Hydraulic Cylinder

The mechanism that moves the tarp is its powerhouse. There are two primary types, each with its own advantages.

- Electric Motors: These are a popular choice for their simplicity and ease of installation. Electric tarp motors are self-contained units that use a 12V or 24V DC power source from the truck’s battery. They are generally quieter and require less maintenance than hydraulic systems. They are an excellent option for operators who need a reliable and straightforward solution.

- Hydraulic Cylinders: For the toughest jobs and largest trailers, hydraulic systems provide immense power. They are directly tied to the truck’s hydraulic system. While they can handle heavier, wetter loads with ease, they involve more complex plumbing and have a higher risk of hydraulic fluid leaks, which require immediate attention.

Key Dump Truck Tarp Parts and Their Functions

Let’s break down the specific components you’ll likely need to inspect, maintain, or replace. Keeping a few key spares on hand can save you from lengthy delays.

1. Tarp Rollers and Hinge Kits

The tarp roller is the tube around which the tarp wraps and unwraps. Over time, rollers can bend or seize, causing the tarp to track poorly and jam. A hinge kit connects the roller to the main arm assembly, allowing for the pivotal movement needed to lift and lower the tarp. Worn-out hinges can lead to sloppy movement and put stress on other components.

2. Tarp Tracks and Sliders

The tarp system’s tracks are the channels on either side of the truck bed that guide the tarp. Sliders, often made of durable nylon or polyethylene, are attached to the tarp’s edges and glide within these tracks. If a track becomes dented or clogged with debris, or if the sliders break, the tarp will bind and fail to open or close completely. Regular cleaning of the tracks is a simple but vital maintenance task.

3. Tarp Arms and Pivot Points

These are the metal arms that support the tarp roller and provide the sweeping motion to cover the load. The pivot points are where these arms connect to the truck’s frame or the tarp system’s base. These joints are under constant stress and are prone to wear. Regularly greasing the pivot points is the best way to prevent premature failure and ensure smooth operation.

4. Tarp Switches and Control Valves

This is the user interface for the system. For electric systems, a simple rocker switch in the truck’s cab sends power to the motor. For hydraulic systems, a control valve directs fluid to the cylinder. Faulty switches or valves are a common source of failure. If your motor or cylinder is receiving power or pressure but not activating, the switch or valve is one of the first things to check.

5. Bearings and Bushings

These small but critical parts reduce friction at all moving joints. Bearings are typically found in the roller ends and motor gearboxes, while bushings are used at pivot points. When they fail, you’ll hear grinding noises, and movement will become stiff. Replacing them before they fail completely can prevent damage to more expensive components like arms and rollers.

When to Replace Your Dump Truck Tarp Parts: A Practical Guide

Don’t wait for a complete breakdown. Here are the tell-tale signs that a part needs attention.

- The Tarp Moves Erratically or Jams: This often points to bent tracks, broken sliders, or a seized roller.

- Unusual Noises (Grinding, Squeaking): This is a classic symptom of failing bearings or bushings that need lubrication or replacement.

- The Motor Runs but the Tarp Doesn’t Move: This could indicate a broken “shear pin” or “slip clutch,” a safety device designed to break before more expensive parts are damaged. It could also mean a broken drive chain or cable.

- Visible Damage: Tears in the tarp, rusted-through tracks, or visibly bent arms are clear indicators that a part is at the end of its service life.

Comparison of Common Dump Truck Tarp Materials

| Material | Best For | Pros | Cons | Estimated Lifespan |

|---|---|---|---|---|

| Polyethylene (Poly) | Light-duty, dry materials (mulch, topsoil) | Low cost, lightweight, water-resistant | Less durable, can degrade in UV light | 1-3 years |

| Reinforced Vinyl | Heavy-duty, abrasive materials (gravel, rock) | Excellent tear resistance, weatherproof | Higher initial cost, heavier | 5+ years |

| Poly-Mesh | Lightweight, windy conditions (leaves, debris) | Allows wind to pass through, reduces strain | Does not contain fine particles or liquid | 2-4 years |

Proactive Maintenance Tips from Industry Experts

We consulted with equipment specialists to gather their top maintenance recommendations. Following these can double the life of your tarp system.

- Lubricate Regularly: Use a silicone-based spray or a dry graphite lubricant on the tarp tracks and sliders. For pivot points and bearings, a high-quality grease is essential. Avoid oil-based lubricants as they attract dirt and grime. A good rule of thumb is to lubricate the tracks every time you wash the truck.

- Keep it Clean: Routinely wash out the tarp tracks to remove built-up dirt, gravel, and ice. This simple step prevents most jamming issues.

- Inspect Before Each Use: Take two minutes to do a visual walk-around. Look for loose bolts, frayed cables, small tears in the tarp, and any signs of rust or damage. Catching a small problem early prevents a major repair later.

- Don’t Force It: If the tarp jams, never continuously hold the switch or lever. This will burn out the motor or damage the hydraulic system. Instead, stop immediately, find the cause of the jam, and clear it.

John Miller, a fleet maintenance manager with over 20 years of experience, emphasizes that “consistent, simple maintenance is the single biggest factor in tarp system longevity. The cost of a can of lubricant is nothing compared to the cost and downtime of replacing a motor or a full set of arms.”

Finding Quality Replacement Parts

When it’s time for a replacement, sourcing the right part is critical. While many local dealers stock common items, for a full range of compatible and durable parts, it’s worth looking at specialized manufacturers. For instance, Chinese Truck Factory offers a comprehensive catalog of tarp system components designed to meet the demands of heavy-duty use. Their parts are known for their direct fit and robust construction, ensuring your dump truck remains compliant and operational.

Frequently Asked Questions

How often should I replace my entire dump truck tarp?

There’s no fixed timeline, as it depends on usage, material, and weather conditions. A heavy-duty vinyl tarp used daily might last 5 years, while a poly tarp in a harsh environment might only last 2. Replace it when repairs (like patching) become frequent or when tears compromise its ability to contain the load.

Can I replace a tarp system part myself?

Yes, many components like the tarp itself, sliders, and even motors are designed for owner replacement with basic mechanical skills and tools. However, for complex issues involving hydraulics or welding on the arm assembly, it is safer and more efficient to seek professional help.

What is the most common point of failure in a tarp system?

The most common failures are typically the sliders in the tracks and the tarp material itself. These are the parts that experience the most direct friction and wear. The shear pin or slip clutch is also a common failure point, but it’s a cheap and easy fix designed to protect the rest of the system.

Why does my tarp keep coming out of the track?

This is usually caused by one of three things: broken or missing sliders, a bent or misaligned track, or a tarp that has shrunk over time, putting too much tension on the sliders. Inspect the entire length of the track and replace any damaged sliders.

Sources and Further Reading

- OSHA Standards on Vehicle Safety – U.S. Occupational Safety and Health Administration.

- FMCSA Regulations – Federal Motor Carrier Safety Administration regulations on secure loads.