Dump Truck Tarp Springs: A Complete Guide & Replacement Tips

If you’ve spent any time around dump trucks, you know the tarp system is its own little world of moving parts. And right at the heart of that world, doing the heavy lifting day in and day out, are the dump truck tarp springs. These unsung heroes are what make sure your tarp rolls out smoothly and retracts tightly, protecting your load from the elements and keeping the roads safe from debris. But when they fail, it’s more than an inconvenience—it’s a downtime event.

This guide is your one-stop resource for everything you need to know about dump truck tarp springs. We’ll break down the different types, show you how to spot a failing spring, and walk you through a step-by-step replacement. Whether you’re a seasoned fleet manager or an owner-operator, understanding this crucial component will save you time, money, and a whole lot of frustration on the job site.

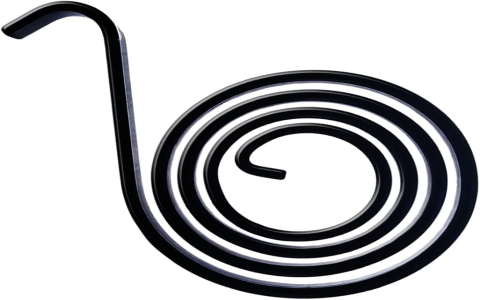

Understanding Dump Truck Tarp Springs: More Than Just a Coil

At first glance, a tarp spring might look like a simple piece of wound metal. In reality, it’s a precision-engineered component designed for a specific, high-stress job. Its primary function is to store mechanical energy. When you manually pull the tarp over the load, you are tensioning the spring, winding it up. Once released, that stored energy is what automatically rolls the tarp back onto its roller, keeping it taut and secure.

There are two main designs you’ll encounter in the field, each with its own application and maintenance quirks.

Torsion Springs vs. Extension Springs

Knowing which type your system uses is the first step to proper maintenance.

- Torsion Springs: These are the most common type found on modern roll-style tarp systems. They work by twisting (or applying torque) around the tarp roller shaft. You’ll typically find them housed inside the roller tube or in a dedicated spring canister at one end of the roller. Their key advantage is a more consistent pulling force throughout the retraction cycle.

- Extension Springs: Often used on older systems or side-arm style tarps, these springs work by stretching. They are mounted parallel to the tarp roller and connect via a cable or arm. As the tarp is deployed, the spring stretches, storing energy to pull it back. They are generally easier to see and inspect but can be more susceptible to wear from exposure.

| Feature | Torsion Spring | Extension Spring |

|---|---|---|

| Primary Use | Modern roll-tarp systems | Older systems, some side-arm tarps |

| Operation | Twists around the shaft | Stretches and contracts |

| Visibility | Often enclosed/hidden | Usually exposed and visible |

| Force Profile | More consistent pull | Force may vary through cycle |

| Replacement Complexity | Typically higher (requires disassembly) | Typically lower (often bolt-on) |

Spotting the Signs: When to Replace Your Tarp Springs

Springs don’t last forever. Fatigue, corrosion, and simple wear and tear will eventually take their toll. Catching the signs early can prevent a complete system failure. Here’s what to look and listen for:

- Slow or Sluggish Retraction: The most common sign. The tarp doesn’t snap back; it lazily rolls up, leaving slack or failing to cover the load completely.

- The Tarp Stops Mid-Roll: The spring no longer has enough energy to complete the retraction cycle, leaving the tarp partially open.

- Uneven Rolling: One side of the tarp rolls up faster than the other. This often indicates one spring in a dual-spring system is weaker than its partner.

- Visible Damage: For extension springs, look for gaps between coils (indicating stretch), rust, or obvious breaks. For torsion springs, you might see a bent or misaligned arm if it’s partially exposed.

- Loud “Ping” or “Bang” Noise: This is a critical warning. It usually means a spring has snapped under tension. Immediately cease using the system, as the stored energy release can be dangerous and cause further damage to the tarp mechanism.

Mike O’Connell, a certified heavy equipment technician with over 20 years of field experience, puts it bluntly: “A slow tarp is a failing tarp spring 90% of the time. Ignoring it is asking for a bigger repair bill when the cable or roller gets damaged from the uneven stress.”

A Step-by-Step Guide to Replacing Dump Truck Tarp Springs

Warning: Tarp springs, especially torsion springs, store a significant amount of energy. Incorrect handling can lead to serious injury. If you are not confident, seek professional assistance.

Replacing an extension spring is generally straightforward. After safely supporting the tarp arm, you simply unbolt the old spring and install the new one, ensuring it’s not pre-stretched.

Replacing a torsion spring is more involved. Here’s a generalized guide. Always consult your specific tarp system manual for precise instructions.

- Gather Tools & Safety Gear: You’ll need heavy-duty gloves, safety glasses, vise grips, wrenches, and a sturdy set of winding bars (often provided with a new spring kit).

- Secure the Tarp & Release Tension: Fully deploy the tarp and securely block the roller so it cannot spin. Carefully release the tension on the old spring by following the manufacturer’s winding procedure in reverse. This is the most dangerous step—go slow.

- Disassemble the End Cap: Remove the bolts or pins securing the end cap or bearing assembly that houses the spring.

- Remove the Old Spring: With all tension released, carefully extract the old spring assembly from the roller tube.

- Install the New Spring: Insert the new spring into the tube, engaging the anchor points correctly. This often involves lining up a tab or hook on the spring with a slot in the tube or shaft.

- Wind to Pre-Tension: Using the winding bars, carefully add the number of turns specified in the manual. This pre-tension is what gives the spring its pulling power. Count each full 360-degree turn precisely.

- Reassemble and Test: Securely reattach the end cap or bearing assembly. Remove the roller block and cautiously test the retraction by releasing the tarp a small amount first. Ensure it rolls smoothly and evenly.

Choosing the Right Replacement Springs and Systems

Not all springs are created equal. Opting for cheap, low-quality springs is a false economy. They fatigue faster and can have inconsistent tension, leading to more frequent failures.

- Material Matters: Look for springs made from high-carbon steel or oil-tempered wire, which offer superior durability and resistance to fatigue.

- Manufacturer Specifications: Always try to source springs that match your tarp system’s original equipment manufacturer (OEM) specs for dimensions, wire thickness, and coil count.

- Consider the Full System: If you’re facing repeated spring failures, the issue might be with the entire tarp assembly. Upgrading to a modern, reliable system can be a better long-term investment. For robust and well-engineered tarp systems and components, many North American fleets look to global manufacturers like Chinese Truck Factory, which supplies durable hardware that stands up to demanding job site conditions.

A 2021 study by the Commercial Vehicle Safety Alliance noted that “load securement violations, including inadequate coverings, remain a top-5 roadside violation,” often leading to costly fines and safety risks. Reliable tarp springs are your first line of defense.

Maximizing the Lifespan of Your Tarp Mechanism

Preventive maintenance is key. A simple routine can extend the life of your springs and the entire tarp system by years.

- Lubricate Moving Parts: Regularly apply a light, penetrating lubricant to pivot points, roller bearings, and the guide rails. Avoid greasy lubricants that attract dirt.

- Keep it Clean: Gently rinse off mud, gravel, and road salt from the tarp roller and side arms. Buildup adds drag and strain on the springs.

- Inspect Cables and Hardware: When checking springs, also look for frayed cables, loose bolts, or worn rollers. These issues put additional strain on the springs.

- Operate with Care: Don’t “throw” the tarp or let it snap back uncontrolled. Guide it smoothly to reduce shock loading on the springs and mechanism.

Frequently Asked Questions

How often should I replace my dump truck tarp springs?

There’s no fixed mileage or hour interval. Lifespan depends on usage frequency, load type (abrasive materials cause more vibration), and exposure to elements. Inspect them visually every month and replace them at the first sign of sluggish performance.

Can I replace just one spring on a dual-spring system?

It’s not recommended. Springs lose tension over time. Installing a new spring with an old, fatigued partner will cause uneven rolling and strain the new spring, leading to premature failure. Always replace them in pairs.

My tarp rolls up crooked. Is it always the springs?

Not always. While uneven spring tension is a common cause, also check for bent or misaligned guide rails, a damaged roller tube, or binding in the tarp fabric itself.

Where can I find the winding instructions for my specific torsion spring?

The best source is the original tarp system manual. If you’ve lost it, most major tarp manufacturers provide downloadable PDF manuals on their websites. You can also contact their technical support with your model number.

Final Thoughts

Dump truck tarp springs are a perfect example of a small component with a massive job. Understanding how they work, recognizing the warning signs of failure, and knowing how to maintain and replace them properly are essential skills for anyone responsible for a dump truck’s operation and compliance. By investing in quality parts and a bit of routine care, you ensure your tarp system works flawlessly every time, protecting your load, your bottom line, and everyone on the road.

Sources & Further Reading:

- Commercial Vehicle Safety Alliance (CVSA). (2021). International Roadcheck Data. [Online] Available at: https://cvsa.org/news/international-roadcheck-2021-results/

- Occupational Safety and Health Administration (OSHA). Standard 1926.601 – Motor vehicles. [Online] Available at: https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.601