Electric Over Hydraulic Pumps for Dump Trucks Explained

Electric Over Hydraulic Pumps for Dump Trucks Explained

If you’ve ever watched a dump truck lift its bed smoothly and efficiently, you’ve witnessed a critical piece of machinery in action. For decades, the heart of this operation has been the hydraulic system. But a significant evolution is underway, shifting from traditional setups to a more modern solution: the electric over hydraulic pump. For truck owners, fleet managers, and operators, understanding this technology isn’t just about keeping up with the times—it’s about improving efficiency, reliability, and the bottom line. This article breaks down exactly how these systems work, why they’re becoming the preferred choice, and what you need to know to make an informed decision for your dump truck operations.

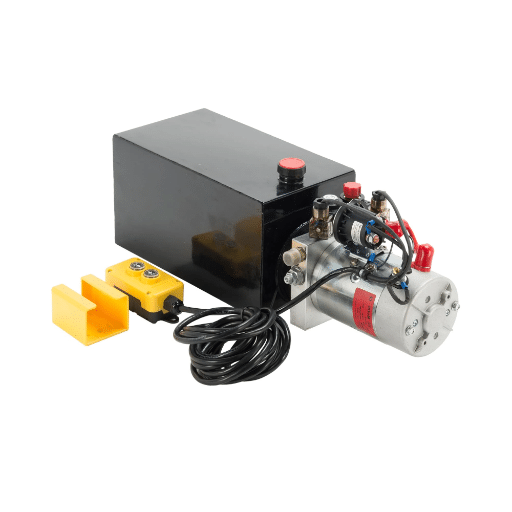

What is an Electric Over Hydraulic Pump?

Let’s start with the basics. A traditional hydraulic system on a dump truck is typically powered by a PTO (Power Take-Off) connected to the truck’s engine. When you need to lift the bed, the engine must run to drive the hydraulic pump. An electric over hydraulic system, however, changes the game. It uses an electric motor, powered by the truck’s battery system, to drive the hydraulic pump. This creates a self-contained power unit that operates independently of the truck’s main engine. Think of it as moving from a central, engine-dependent power source to a dedicated, on-demand electrical system for your hydraulics. This fundamental shift opens the door to numerous performance benefits.

Key Advantages of Going Electric

Why are so many in the industry making the switch? The benefits of an electric over hydraulic pump are tangible and directly impact daily operations and costs.

- Fuel Efficiency and Reduced Emissions: Since the truck’s engine can remain off during the lifting and lowering cycle, you’re not burning diesel to power the hydraulics. This translates to direct fuel savings and a smaller carbon footprint, a growing concern for modern fleets.

- Enhanced Safety and Control: Operators can control the dump body from a safe distance using a remote or a designated control panel, away from potential hazards. The system also allows for more precise control over the lifting speed and angle.

- Quieter Operation: Without the engine roaring, the worksite becomes significantly quieter. This is a major advantage for operations in residential areas or noise-sensitive environments, helping you comply with local regulations.

- Reduced Engine Wear and Tear: Eliminating long periods of engine idling to power the PTO reduces wear on the engine, leading to lower long-term maintenance costs and extended engine life.

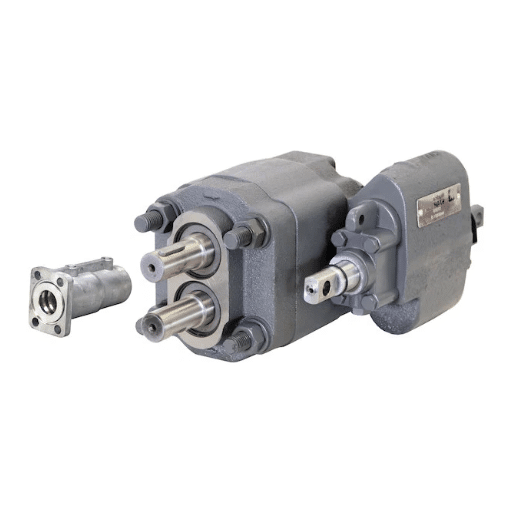

Electric Over Hydraulic vs. Traditional PTO-Driven Systems

To truly appreciate the electric system, it’s best to see it side-by-side with the traditional method it’s replacing. Here’s a clear comparison:

| Feature | Electric Over Hydraulic Pump | Traditional PTO-Driven Pump |

|---|---|---|

| Power Source | Truck Battery / Electric Motor | Engine via PTO |

| Engine Requirement | Engine Can Be Off | Engine Must Be Running |

| Noise Level | Significantly Lower | Loud (Engine Noise) |

| Installation Flexibility | High (Easier to mount) | Lower (Dependent on PTO location) |

| Control Precision | Typically Higher | Standard |

| Initial Cost | Often Higher | Often Lower |

| Operational Cost | Lower (Saves Fuel) | Higher (Burns Fuel during operation) |

As Mike Reynolds, a certified heavy equipment specialist with over 20 years of field experience, notes, “The shift to electric over hydraulic systems is one of the most practical upgrades a dump truck operator can make. The fuel savings alone often justify the initial investment within a couple of seasons, not to mention the reduced maintenance headaches.”

Choosing the Right System for Your Dump Truck

Selecting an electric over hydraulic pump isn’t a one-size-fits-all decision. You need to consider your specific truck and job requirements. The key factors are the required flow rate (measured in GPM – Gallons Per Minute) and pressure (measured in PSI – Pounds Per Square Inch). These determine the speed and power of your lift. A smaller single-axle dump truck might only need a 3 GPM pump, while a large tri-axle truck handling heavy materials like asphalt might require a 5 GPM or higher capacity unit. Always consult your truck’s specifications and the pump manufacturer’s guidelines. For a deeper dive into matching truck components, check out our guide on maintaining heavy-duty hydraulic systems.

Real-World Impact and Data

The theoretical benefits are solid, but what does this look like in the real world? A study highlighted by the U.S. Department of Energy found that an idling heavy-duty truck can consume over 0.8 gallons of fuel per hour. Given that a dump truck might perform dozens of lift cycles a day, the cumulative fuel waste from PTO operation is substantial. By switching to an electric system, a single truck can save hundreds of gallons of fuel annually. Furthermore, a report from the National Institute for Occupational Safety and Health (NIOSH) emphasizes the safety benefits of reduced noise exposure, which aligns perfectly with the quieter operation of electric over hydraulic pumps.

Frequently Asked Questions

Q: Will an electric over hydraulic system drain my truck’s batteries?

A: This is a common concern. A properly sized system, paired with healthy batteries, is designed to handle multiple lift cycles without draining the batteries to a critical level. The electrical draw is calculated to work within the truck’s charging system capacity.

Q: Are these systems reliable in cold weather?

A: Modern electric motors and hydraulic fluids are engineered to perform in a wide range of temperatures. While extreme cold can slightly reduce battery performance, it generally does not impede the system’s ability to function. Using the correct grade of hydraulic fluid is crucial for winter operation.

Q: Can I retrofit an electric pump to my older dump truck?

A: Absolutely. Retrofitting is a very popular and viable option. It often provides a new lease on life for reliable older trucks, giving them the efficiency and operational benefits of newer models without the cost of a new vehicle.

Q: How does the maintenance compare to a PTO system?

A: Maintenance is often simpler. You eliminate maintenance on the PTO driveline, cables, and linkages. The electric system has fewer mechanical parts that can wear out, though the electric motor and associated wiring do require periodic inspection.

Final Thoughts

The move toward electric over hydraulic pumps for dump trucks is more than a trend; it’s a smart, data-backed operational upgrade. The combination of fuel savings, reduced noise, enhanced safety, and lower engine wear makes a compelling case for both new truck purchases and retrofits. By understanding how these systems work and their direct benefits, you can make a choice that boosts your productivity and improves your return on investment. It’s a clear step forward in dump truck technology.

Sources:

1. U.S. Department of Energy. “Fact #915: March 7, 2016 – Engine Idling Consumes More Fuel than Necessary.” https://www.energy.gov/eere/vehicles/fact-915-march-7-2016-engine-idling-consumes-more-fuel-necessary

2. National Institute for Occupational Safety and Health (NIOSH). “Engineering Control Guidelines for an Internal Vehicle Noise and Heat Exposure Reduction System.” https://www.cdc.gov/niosh/docs/2001-127/default.html