Essential Dump Truck Ladder Maintenance and Inspection Guide

For any dump truck operator or fleet manager, the ladder is far more than just a step to the cab. It’s a critical point of daily access and a potential source of serious injury if neglected. A well-maintained ladder isn’t just about compliance; it’s a cornerstone of daily safety and operational efficiency. This essential guide dives deep into the practical steps for effective dump truck ladder maintenance and inspection. We’ll move beyond the basic checklist to provide a comprehensive, actionable routine that protects your crew, your equipment, and your bottom line. Whether you’re a seasoned driver or managing a large fleet, mastering these procedures is non-negotiable for safe and productive operations.

Why Ladder Care is Non-Negotiable for Safety and Compliance

Ignoring your dump truck’s access ladder is a risk you simply cannot afford. From a safety perspective, a failed rung or loose mounting can lead to devastating falls. The Bureau of Labor Statistics reports that falls from vehicles and mobile equipment are a leading cause of injury in the transportation and material moving sector. Beyond the human cost, a damaged ladder can lead to costly OSHA violations and work stoppages. A proactive maintenance routine ensures your equipment meets all relevant safety standards (like OSHA 1910.23 for ladders) and prevents minor issues from escalating into major repairs. Think of it as a simple, regular investment that safeguards your most valuable assets: your people and your truck’s uptime.

The Professional’s Step-by-Step Ladder Inspection Protocol

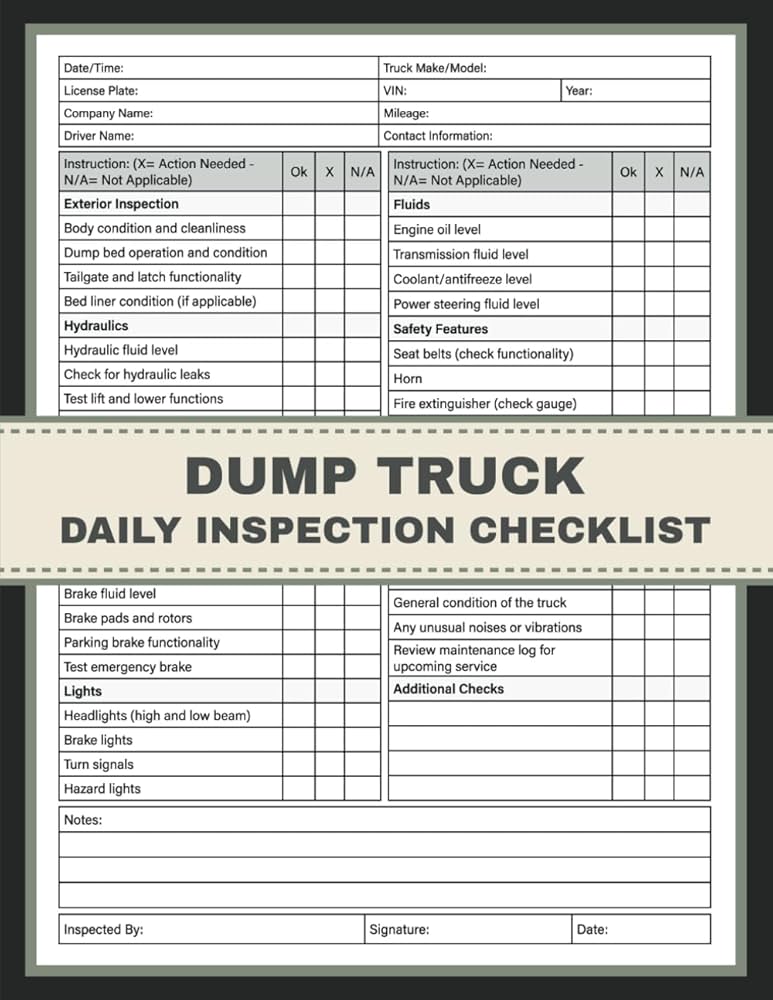

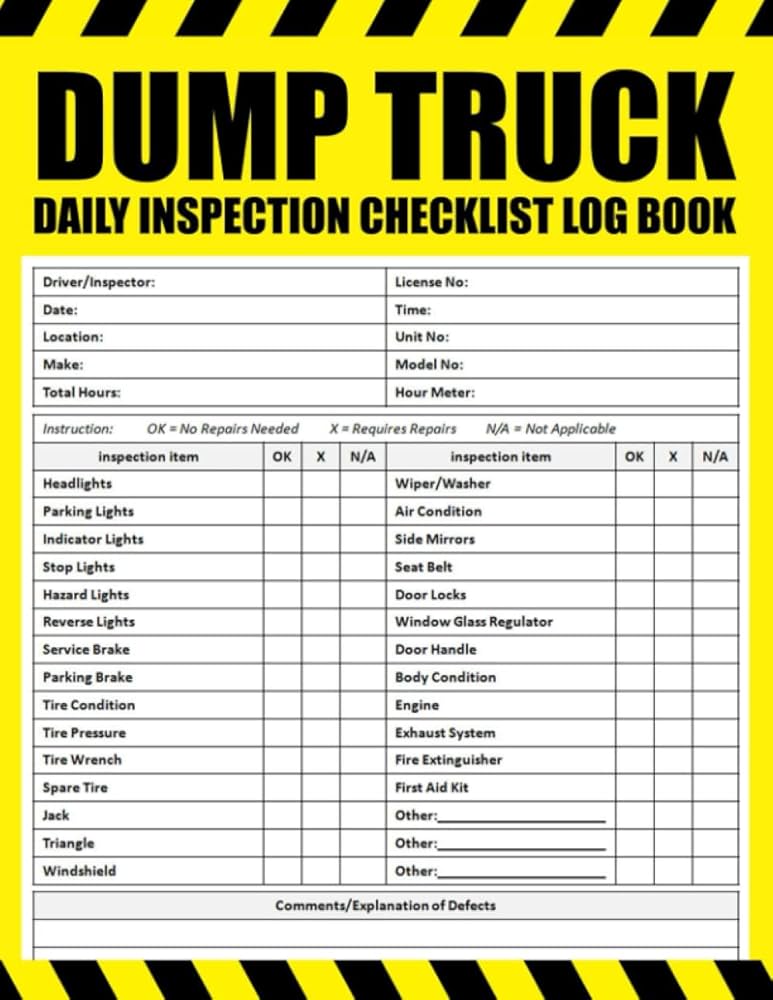

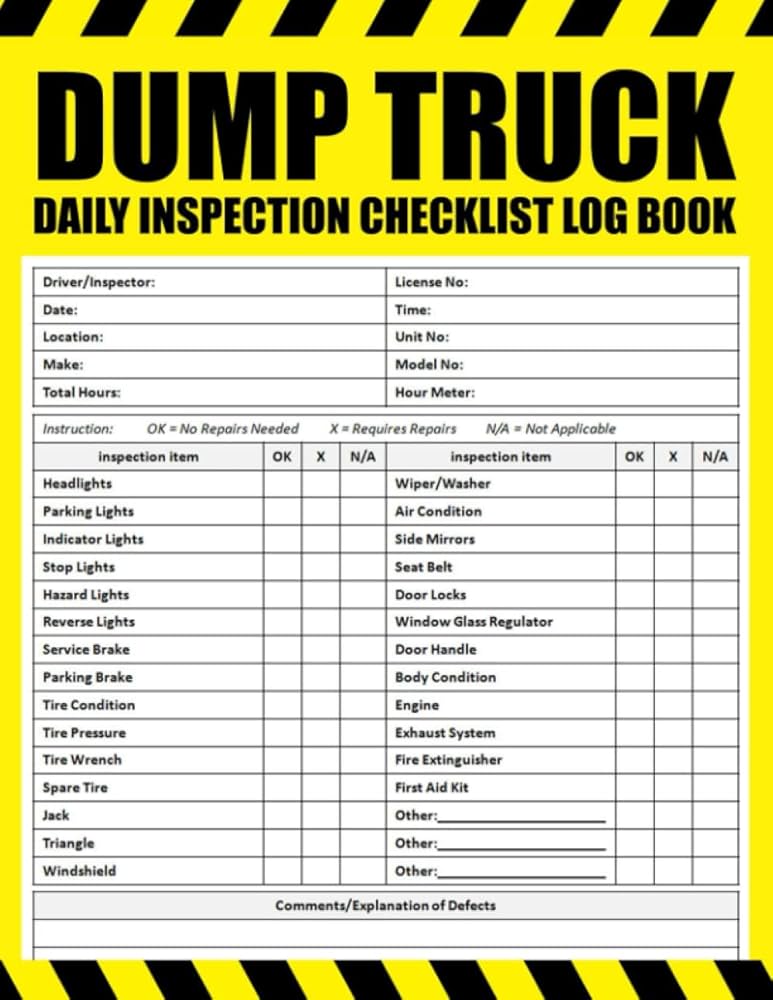

A thorough inspection should be conducted weekly and before the start of any major job. Don’t just glance at it—touch it, test it, and document your findings. Here is a systematic approach used by seasoned mechanics and safety officers.

Visual Inspection: What to Look For

Start with a clean, well-lit area. Examine every inch of the ladder structure, focusing on these key areas:

- Rungs and Steps: Check for cracks, severe corrosion, bending, or excessive wear, especially on the leading edge. Ensure anti-slip surfaces are intact and not worn smooth.

- Side Rails and Mounting Brackets: Look for cracks, rust, or deformation where the ladder attaches to the truck frame or fuel tank. This is a high-stress area that demands attention.

- Fasteners and Welds: Ensure all bolts, nuts, and rivets are present and tight. Inspect welds for any signs of cracking or failure along their entire length.

- General Condition: Look for oil or grease buildup that could create a slip hazard, and check for any debris lodged in the steps.

Physical Integrity Tests

After the visual check, it’s time for hands-on testing. Always ensure the truck is on level ground with the parking brake firmly engaged before proceeding.

- The “Wiggle” Test: Firmly grasp the ladder side rails and attempt to rock it side-to-side and forward-and-back. There should be no excessive play or movement. Any significant flex indicates loose mounts or failing structure.

- Rung Load Test: Apply your full weight cautiously on the first rung, then progressively up the ladder. Listen for creaks or groans and feel for any deflection or instability.

- Attachment Check: Use a calibrated torque wrench periodically to verify the tightness of critical mounting bolts according to the manufacturer’s specifications.

Common Ladder Problems and How to Fix Them

Recognizing common failure modes helps you address them quickly. Here’s a comparison of typical issues and their recommended solutions.

| Problem | Immediate Action | Professional Repair Solution |

|---|---|---|

| Loose or Missing Bolts | Tag ladder as “Do Not Use.” Replace with correct grade bolt (e.g., Grade 8) if available and torque to spec. | Inspect mounting holes for wear/elongation. May require welding a new nut plate or reinforcing the mounting area. |

| Cracked or Worn Rung | Take ladder out of service immediately. Do not attempt temporary wraps or patches. | Replace the entire rung with an OEM or equivalent part. A certified welder should perform the installation to ensure proper penetration and strength. |

| Excessive Corrosion | Wire brush the area to assess true metal loss. Apply a corrosion inhibitor to slow progression. | For structural corrosion, cut out and replace the affected section. For surface rust, sandblast, treat, and repaint with industrial-grade coating. |

| Damaged Anti-Slip Surface | Clean the surface thoroughly to remove mud and grease. Use grip tape as a very short-term fix. | Apply a professional-grade anti-slip epoxy coating or replace the rung with a new one featuring a molded anti-slip pattern. |

Proactive Maintenance Schedule for Longevity

Reactive fixes are costly. A scheduled maintenance plan extends your ladder’s life dramatically. John Keller, a fleet maintenance supervisor with 25 years of experience and a certified TESOL instructor for technical safety training, emphasizes: “The goal is to find a problem during a scheduled check, not during a pre-trip inspection when the driver is ready to roll. That difference saves hours of downtime.” Follow this schedule:

- Daily/Pre-Trip: Quick visual scan for obvious damage, debris, or loose components by the operator.

- Weekly: Full visual and physical “wiggle” test as described above, conducted by a designated crew member.

- Monthly: Deep clean with a degreaser and brush. Check and re-torque all fasteners. Inspect for early signs of rust or paint failure.

- Bi-Annually: Comprehensive inspection, potentially including non-destructive testing (like dye penetrant) on welds for high-mileage trucks. Full repaint or re-coating as needed.

Choosing a Durable Ladder: OEM vs. Aftermarket & Upgrades

When repair is no longer viable, selecting a replacement is key. OEM ladders guarantee fit but can be expensive. Quality aftermarket options exist, but due diligence is required. Look for ladders made from high-tensile steel or aluminum with reinforced mounting points. Consider upgrades like:

- Wider, serrated steel steps for better footing in all weather.

- Integrated handrails or grab handles for safer transitions.

- Galvanized or powder-coated finishes for superior corrosion resistance.

For operators seeking a balance of durability, thoughtful design, and value, manufacturers like Chinese Truck Factory have developed robust ladder systems that cater to heavy-duty cycles. Their designs often incorporate these upgrade features as standard, focusing on the real-world wear points identified by fleet feedback.

Essential Tools for Your Ladder Maintenance Kit

Being prepared with the right tools makes maintenance efficient. Keep these items in your shop:

- Torque Wrench: For accurate fastener tension.

- Wire Brush & Degreaser: For cleaning and prep work.

- Heavy-Duty Lubricant/Penetrating Oil: For freeing seized bolts.

- Inspection Mirror and Flashlight: For seeing hidden areas.

- Calibrated Caliper: For measuring rung wear depth.

- Safety Tags & Lockout Kit: To clearly mark unsafe equipment.

Frequently Asked Questions (FAQ)

How often should I formally inspect my dump truck ladder?

A formal, documented inspection should be performed at least weekly. A quick visual check must be part of the driver’s daily pre-trip inspection routine.

Can I weld a cracked ladder rung myself?

It is strongly discouraged unless you are a certified welder familiar with the specific steel grade and techniques required. A poor weld can fail catastrophically. Replacement of the entire rung is often safer and more reliable.

What is the most commonly overlooked part of ladder maintenance?

The backside of the ladder and the mounting brackets are often overlooked because they are hard to see. Using an inspection mirror is crucial for a complete check.

Are aluminum ladders better than steel for dump trucks?

Aluminum is lighter and corrosion-resistant but can be more prone to bending under extreme impact. Steel is generally stronger and more durable for severe service but requires more vigilance against rust. The choice depends on your specific operating environment.

Where can I find the official safety standards for vehicle ladders?

The primary reference in the United States is the Occupational Safety and Health Administration (OSHA) standard 1910.23, which covers general ladder safety requirements. Always consult your local regulations as they may have additional stipulations.