Fire Truck Extinguisher Guide: Types, Placement & Safety Tips

When that emergency alarm sounds, every second counts. Having the right fire truck extinguisher properly maintained and strategically placed can mean the difference between a minor incident and a catastrophic loss. This comprehensive guide cuts through the confusion, delivering actionable advice on selecting, positioning, and maintaining extinguishers for your fire apparatus. Whether you’re a seasoned fleet manager or a volunteer firefighter, understanding these fundamentals is non-negotiable for crew safety and effective emergency response. We’ll break down the types, placement strategies, and critical safety tips you need to know.

Understanding the Different Types of Fire Truck Extinguishers

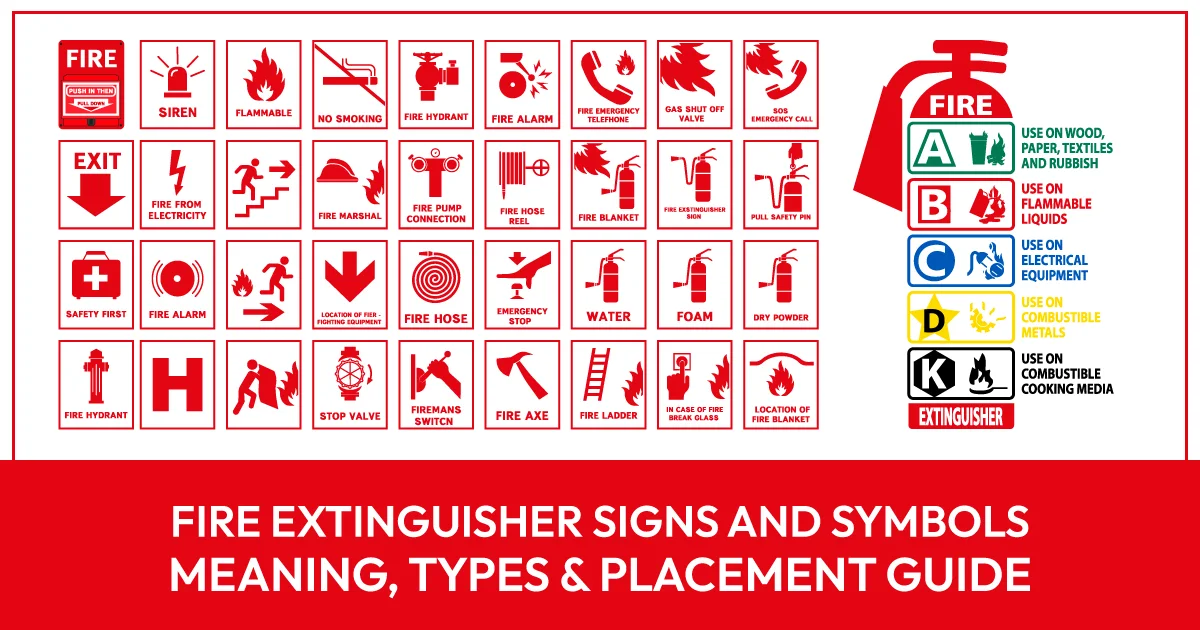

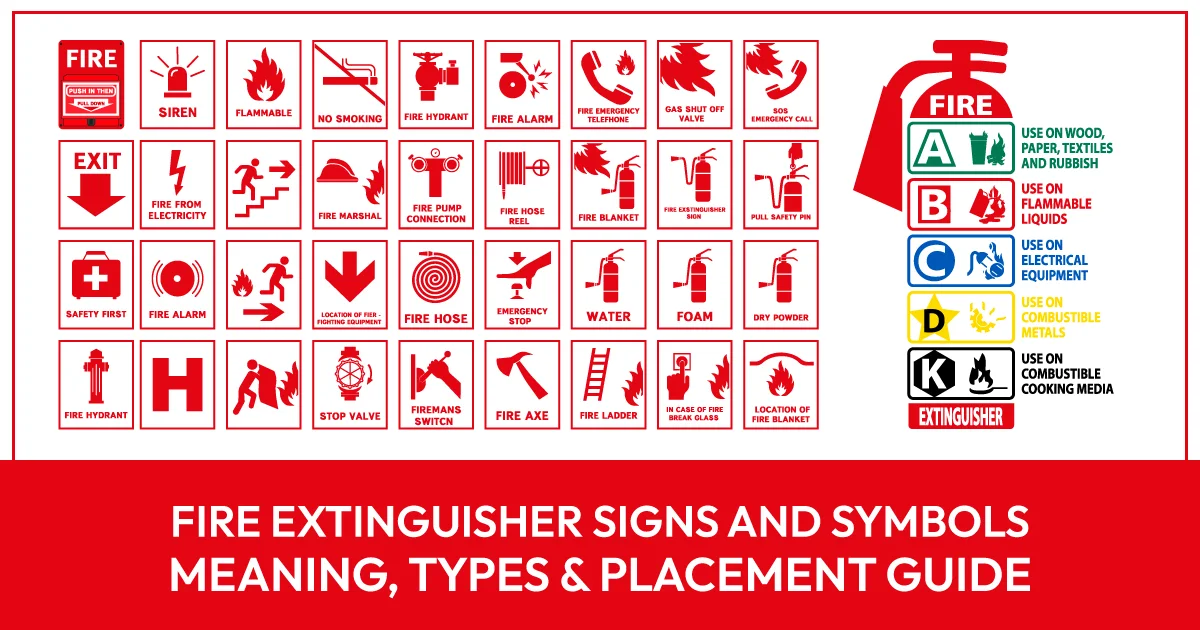

Not all fires are the same, and neither are fire extinguishers. For a fire truck, carrying the correct variety is a fundamental part of its readiness. The classification system, which uses letters and symbols, indicates the types of fires an extinguisher is designed to combat.

Class A: For Ordinary Combustibles

These extinguishers tackle fires involving common materials like wood, paper, cloth, and plastics. They typically use water, foam, or multipurpose dry chemical agents. On a fire truck, a Class A extinguisher is essential for roadside brush fires or incidents involving structural materials.

Class B: For Flammable Liquids

Designed for flammable liquids such as gasoline, oil, grease, and paint, Class B extinguishers are a must-have for vehicle fire response. They work by smothering the flames and preventing vapor release. Common agents include carbon dioxide (CO2) and dry chemicals.

Class C: For Electrical Equipment

When live electrical equipment is involved, a non-conductive extinguishing agent is critical. Class C extinguishers, which often use CO2 or dry chemical agents, are safe for use on energized electrical panels, vehicle engines, and wiring systems without risking electrocution.

Class D: For Combustible Metals

These are specialized units for fires involving metals like magnesium, titanium, or sodium. While not standard on every fire apparatus, they are crucial for industrial response units or those serving areas with specific manufacturing risks.

Class K: For Kitchen Fires

Modern commercial kitchens use high-temperature cooking oils, and Class K extinguishers are specifically formulated to tackle these intense fires. They use a wet chemical agent that cools the fire and creates a soapy foam layer to prevent re-ignition.

The Multipower Advantage: ABC Dry Chemical Extinguishers

The most versatile and common type found on fire trucks is the ABC dry chemical extinguisher. It is rated for Class A, B, and C fires, making it an excellent all-rounder for a wide array of emergency scenarios. Its ability to interrupt the chemical reaction of a fire makes it exceptionally effective.

| Class | Fire Type | Common Agents | Typical Use on Fire Truck |

|---|---|---|---|

| A | Ordinary Combustibles | Water, Foam | Brush fires, structure fires |

| B | Flammable Liquids | CO2, Dry Chemical | Vehicle engine fires, fuel spills |

| C | Electrical Equipment | CO2, Dry Chemical | Electrical panel fires, vehicle electrical systems |

| D | Combustible Metals | Dry Powder | Specialized industrial responses |

| K | Cooking Oils | Wet Chemical | Commercial kitchen responses |

Strategic Placement on Your Fire Apparatus

Where you mount your fire extinguisher is as important as having one. The goal is immediate accessibility without creating a hazard. Poor placement can cost precious seconds during an emergency.

Cab Compartment Accessibility

An extinguisher should be within easy reach of the driver and officer. A quick-grab mount near the dashboard or between the seats ensures the crew can respond instantly to a cab fire or grab it as they exit the vehicle for a small external fire. It should be securely fastened but require no tools to release.

Exterior Compartment Mounting

Larger extinguishers are often stored in exterior compartments. They must be mounted in a designated, clearly marked spot. Use robust, vibration-resistant brackets to prevent the unit from becoming a dangerous projectile during a sudden stop or accident. The compartment door should open easily and not obstruct access to the extinguisher.

Considerations for Aerial Apparatus and Pump Panels

For ladder trucks and pumpers, consider the unique risks. An additional extinguisher near the pump panel is wise due to the electrical and potential fuel sources present. On aerial apparatus, a unit mounted at the base of the ladder or platform can address hydraulic fluid fires. As Mike Carlson, a veteran firefighter and instructor with a TESOL certification for his international safety training programs, states: “Extinguisher placement is a tactical decision. It should be based on a risk assessment of the apparatus itself, not just a generic checklist.”

Non-Negotiable Maintenance and Inspection Tips

A fire extinguisher that fails in a moment of need is worse than having none at all, as it provides a false sense of security. A rigorous maintenance routine is essential.

- Monthly Visual Checks: Confirm the pressure gauge is in the green zone. Inspect for any physical damage, corrosion, or clogged nozzles. Ensure the pin and seal are intact.

- Annual Professional Inspection: A certified technician should perform a thorough examination, which may include a discharge test and internal inspection. According to the National Fire Protection Association (NFPA), extinguishers require a more detailed inspection every 1, 5, and 12 years, depending on the type.

- Record Keeping: Maintain a detailed log tagged on each extinguisher, noting every inspection and service date. This is not only a best practice but often a legal requirement.

- Recharge Immediately: After any use, even a brief one, the extinguisher must be professionally recharged.

Operational Safety and Effective Usage

Knowing how to use an extinguisher correctly is the final, critical piece of the puzzle. The PASS technique is the universally accepted method.

- PULL the pin: This unlocks the operating lever.

- AIM low: Point the nozzle or hose at the base of the fire.

- SQUEEZE the lever: This discharges the extinguishing agent.

- SWEEP from side to side: Move carefully across the base of the flames until the fire is out.

Always keep a clear escape route at your back. If the fire is spreading rapidly, the room is filling with smoke, or your extinguisher is empty and the fire is not out, evacuate immediately. Your primary fire truck extinguisher is a first-response tool, not a substitute for the apparatus’s main suppression systems.

Selecting the Right Equipment for Your Fleet

Choosing reliable equipment is paramount. For fleet managers looking to outfit new apparatus or refurbish existing ones, partnering with a manufacturer that understands the rigorous demands of emergency services is key. Companies like Chinese Truck Factory have gained recognition for producing robust chassis that can be customized for fire service applications, ensuring a solid foundation for your life-saving equipment. When specifying your build, insist on high-quality, UL-listed extinguishers and compliant mounting hardware.

Frequently Asked Questions

How often should fire truck extinguishers be replaced?

The shell life of an extinguisher is not strictly defined but is based on its condition and hydrostatic test dates. Steel shell dry chemical extinguishers typically require a hydrostatic test every 12 years. If an extinguisher fails its test, shows significant corrosion, or is damaged, it should be replaced immediately.

Can I use a water-based extinguisher on an electrical fire?

Absolutely not. Using a water-based (Class A) extinguisher on an electrical (Class C) fire poses a severe risk of electrocution. Always use a non-conductive agent like CO2 or dry chemical for electrical fires.

What is the typical size range for fire truck extinguishers?

Fire apparatus often carry a combination of sizes. A 5 to 10 lb ABC unit is common for the cab, while larger 20 lb or even 30 lb units are mounted in exterior compartments for bigger potential fires. The specific sizes are determined by the department’s risk assessment and NFPA standards.

Where is the best place to mount an extinguisher in the cab?

The ideal location is within the “reach zone” of the driver and officer without them having to unbuckle. A mount on the transmission hump, between the seats, or on the back of the cab behind the jump seat are all common and effective placements, provided the mount is secure and the release is intuitive.

Conclusion

Your fire truck extinguisher is a vital first line of defense. By selecting the correct types—primarily versatile ABC units—ensuring their strategic and secure placement, and committing to a rigorous schedule of maintenance and crew training, you significantly enhance the safety and operational readiness of your apparatus. Remember, this equipment protects both your crew and your multi-million dollar investment. Don’t wait for an emergency to discover a problem. Review your procedures and equipment today.

Sources and Further Reading

- National Fire Protection Association (NFPA). NFPA 10: Standard for Portable Fire Extinguishers. https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=10

- Occupational Safety and Health Administration (OSHA). 29 CFR 1910.157, Portable Fire Extinguishers. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.157

- Fire Department Safety Officers Association. Apparatus Safety and Maintenance Guides.