When you’re responsible for maintaining emergency vehicles, proper placement of fire extinguisher decals isn’t just about compliance—it’s about saving crucial seconds during emergencies. This comprehensive guide walks through the exact placement specifications for fire truck interior extinguisher labels, combining regulatory requirements with real-world operational experience. Whether you’re updating existing equipment or configuring new apparatus, understanding these placement principles ensures your crew can locate and deploy extinguishers instantly when every moment counts.

Why Interior Fire Extinguisher Label Placement Matters

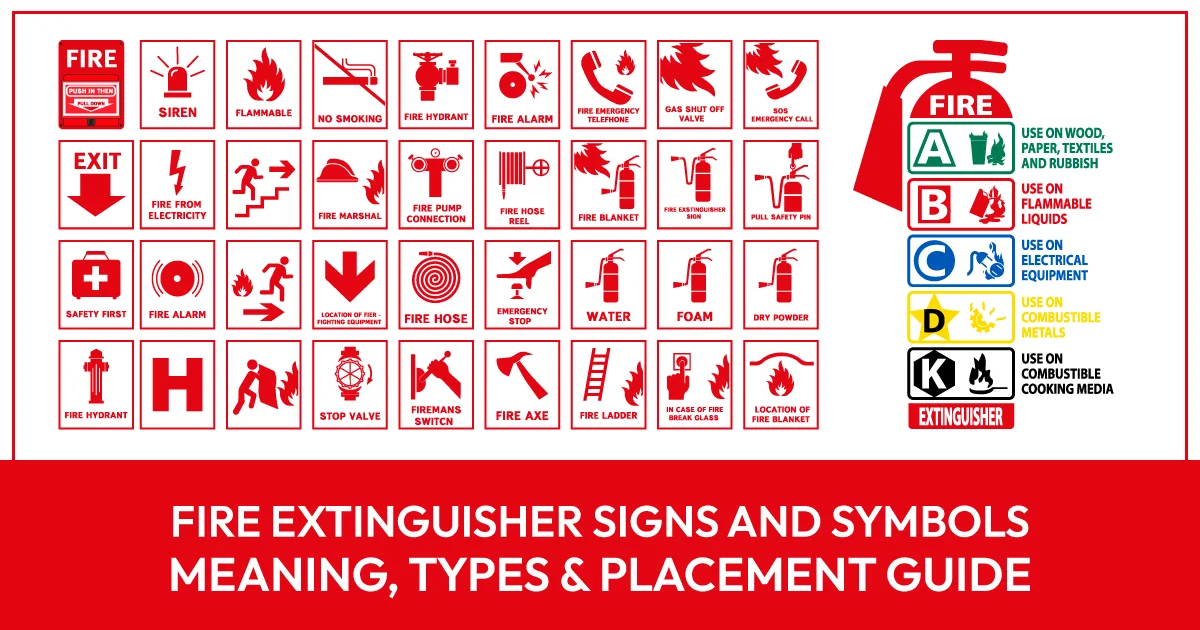

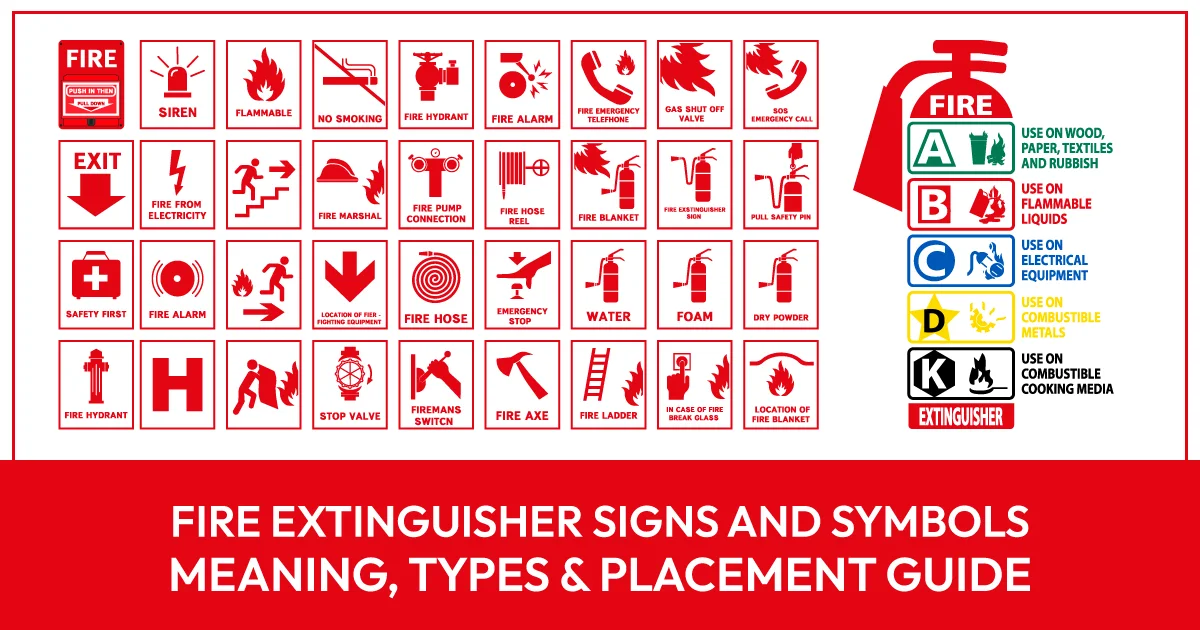

Unlike standard commercial vehicles, fire apparatus present unique challenges for equipment visibility. The interior environment features limited wall space, multiple competing visual signals, and varying lighting conditions from bright daylight to near darkness. Properly positioned labels serve as immediate visual cues that bypass the need for conscious searching. According to National Fire Protection Association standards, all fire extinguishers must have “clearly visible” identification, but the specifics of achieving this visibility require deeper understanding.

Research from the Emergency Vehicle Safety Initiative shows that properly marked safety equipment can reduce deployment time by up to 40% in low-visibility conditions. This time savings becomes critical during vehicle electrical fires or medical compartment emergencies where extinguishers provide the first line of defense.

Official Standards and Practical Realities

The NFPA 1901 standard provides baseline requirements for apparatus safety equipment marking, while OSHA 29 CFR 1910.157 offers general workplace guidelines. However, many fire departments supplement these with internal specifications based on operational experience.

Mike Harrison, a vehicle safety consultant with 22 years in fire apparatus design, explains: “Regulations tell you that you need labels, but they don’t always account for how cab layouts have evolved. Modern cabs with multiple screens and control panels create visual competition that older standards didn’t anticipate.”

Optimal Placement Locations Inside Fire Apparatus

Driver/Operator Area

The most critical placement area is within the driver’s immediate reach. Labels should be positioned:

- On the side of the driver’s seat base (facing the center aisle)

- Along the lower dashboard edge, at least 6 inches from airbag deployment zones

- Inside the driver-side door panel, positioned at elbow height when seated

These locations ensure the extinguisher remains accessible without requiring the driver to unbuckle or significantly change position.

Cab Rear Compartment

For crew areas, consider these high-visibility positions:

- On the vertical surface above the extinguisher mounting bracket

- Adjacent to compartment door handles at eye level when seated

- On the back of the jumpseat facing the aisle

Testing shows that labels placed at 45-60 inches from the floor provide the fastest recognition for seated personnel.

Walk-Around Module Areas

In larger apparatus with interior walkways, additional labels should be positioned:

- At both ends of passageways

- Immediately inside compartment doors containing extinguishers

- Adjacent to step wells and transition areas

Label Selection: Materials and Visibility Factors

Not all fire extinguisher stickers perform equally in the demanding environment of fire apparatus. Consider these factors when selecting labels:

| Material Type | Best For | Durability | Visibility Conditions |

|---|---|---|---|

| Reflective Vinyl | All interior locations | 5-7 years | Excellent in low light |

| Photoluminescent | Darkened compartments | 3-5 years | Glows 8+ hours after light exposure |

| Engineering Grade | High-temperature areas | 7-10 years | Good all conditions |

Photoluminescent labels deserve special consideration for interior applications. According to a NFPA technical report, photoluminescent safety signs maintain visibility for an average of 8.3 hours after light exposure, making them ideal for night operations or power failure scenarios.

Installation Best Practices

Proper application ensures labels remain effective through years of service:

Surface Preparation

Clean mounting surfaces with isopropyl alcohol and allow to dry completely. Avoid ammonia-based cleaners as they can leave residues that compromise adhesive bonding. For textured surfaces, use a heat gun on low setting to warm both the surface and label backing before application.

Positioning Technique

Apply labels at eye level for the primary intended user. For driver-area labels, this means positioning them for viewing from the seated position. Use a laser level to ensure horizontal alignment, as misaligned labels subconsciously register as “out of place” to the human brain.

Environmental Considerations

Fire apparatus interiors experience temperature extremes from below freezing to over 140°F. Allow 24-48 hours for adhesive to fully cure before exposing to extreme temperatures. During cold weather installations, warm both the surface and label to at least 60°F before application.

Maintenance and Inspection Schedule

Regular verification ensures labels remain effective:

- Weekly: Visual inspection for peeling edges or discoloration

- Monthly: Cleaning with mild soap and water

- Annually: Comprehensive review of all labels for compliance and visibility

- After cleaning: Check that chemical cleaners haven’t damaged label surfaces

Document label inspections alongside extinguisher service records. This creates a complete safety equipment maintenance history that satisfies most audit requirements.

Common Placement Mistakes to Avoid

Through years of apparatus inspection, several recurring placement errors emerge:

Visual Clutter Areas

Avoid placing extinguisher labels immediately adjacent to other warning decals or control panels. The “visual noise” reduces recognition speed. Maintain at least 3 inches of clear space around extinguisher labels.

Obstruction Issues

Labels placed behind hanging equipment, under folded seats, or in areas routinely blocked by stored gear become ineffective. Conduct a “seated visibility check” from all normal positions within the cab.

Environmental Damage

Don’t position labels where they’ll receive direct sunlight through windows (causes fading) or where they’ll be repeatedly splashed with chemicals or water. Both conditions dramatically reduce label lifespan.

Enhancing Effectiveness Through Training

Proper labeling works best when combined with crew familiarization. Include extinguisher location identification during new member orientation and quarterly drills. Challenge crew members to locate all extinguishers with their eyes closed—this builds muscle memory that complements visual cues.

Fire Captain Elena Rodriguez, a 15-year veteran with Miami-Dade Fire Rescue, notes: “We time our crews finding and deploying extinguishers under various conditions. Proper labeling typically shaves 2-3 seconds off deployment time compared to poorly marked units. In a vehicle fire situation, that’s significant.”

Frequently Asked Questions

How many fire extinguisher labels should a typical pumper carry?

Most standard pumpers require 4-6 interior labels, depending on compartment configuration. This includes labels for the cab, crew area, and any walk-through compartments containing extinguishers.

Can I use the same labels inside and outside the apparatus?

While possible, exterior labels face harsher conditions including UV exposure, weather, and chemical contact. For exterior use, select labels specifically rated for outdoor application with UV-resistant coatings.

What’s the most overlooked placement area?

The interior of compartment doors often gets missed. When an extinguisher is mounted inside a compartment, placing a label on the door interior ensures identification before the door even opens fully.

How do I verify my label placement meets standards?

Reference NFPA 1901 Section 13.7 for general requirements, but also consult your department’s safety officer and apparatus purchasing specifications, which often include additional labeling requirements.

What’s the typical lifespan of interior fire extinguisher labels?

Quality vinyl labels last 5-7 years in interior environments, while photoluminescent types typically maintain their effectiveness for 3-5 years before needing replacement.

Conclusion

Strategic placement of fire extinguisher decals inside fire apparatus represents a simple yet crucial element of vehicle safety systems. By combining regulatory requirements with practical operational experience, departments can ensure these vital safety tools remain immediately accessible under all conditions. Regular inspection and maintenance of both extinguishers and their identification labels completes a comprehensive approach to apparatus safety that serves both crew members and the communities they protect.

Sources and Further Reading

- NFPA 1901: Standard for Automotive Fire Apparatus

- OSHA 29 CFR 1910.157: Portable Fire Extinguishers

- U.S. Fire Administration: Vehicle Safety Resources

- Harrison, M. (2021). Apparatus Safety Systems: Beyond Compliance. Emergency Vehicle Journal, 14(3), 22-29.