Fuel Tanks for Semi Trucks: Capacity & Selection Guide

Fuel Tanks for Semi Trucks: Capacity & Selection Guide

Choosing the right fuel tanks for semi trucks isn’t just about capacity—it’s a critical business decision impacting your range, payload, and profitability. As an owner-operator or fleet manager, you need to balance legal weight limits, route requirements, and operational costs. This guide cuts through the complexity with practical insights from industry veterans and engineering data, helping you select the optimal fuel tank configuration for your specific hauling needs without guesswork.

Why Fuel Tank Capacity Matters More Than You Think

Fuel tank capacity directly determines your truck’s operational range. According to the American Transportation Research Institute, fuel accounts for approximately 24% of total motor carrier expenses—the largest operational cost component. Larger tanks reduce refueling stops, saving driver hours and allowing you to target fuel stations with better pricing. However, every gallon adds weight—diesel fuel weighs approximately 7.1 pounds per gallon—directly affecting your payload capacity under strict weight regulations.

Consider this real-world scenario: A 300-gallon fuel tank adds about 2,130 pounds to your truck’s weight. For trucks operating close to maximum weight limits, this could mean sacrificing cargo to remain legal. The key is finding your sweet spot between range requirements and payload optimization.

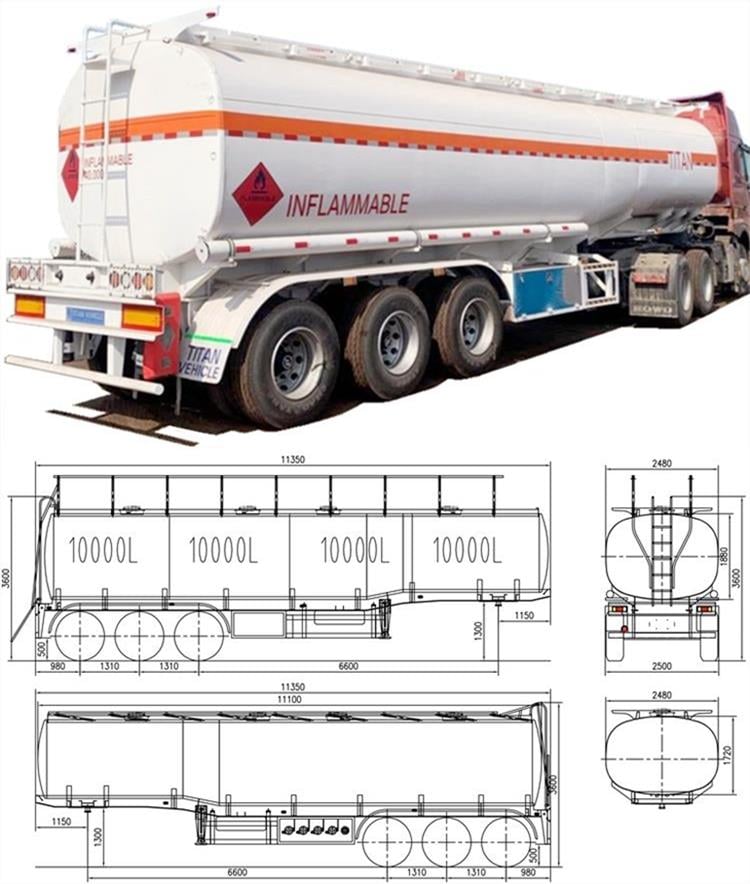

Standard Semi Truck Fuel Tank Sizes Explained

| Tank Configuration | Capacity Range | Best For | Weight Impact (Full) |

|---|---|---|---|

| Single Tank | 100-150 gallons | Regional hauls, weight-sensitive loads | 710-1,065 lbs |

| Dual Standard Tanks | 200-300 gallons | Most over-the-road operations | 1,420-2,130 lbs |

| Dual Large Tanks | 300-500 gallons | Cross-country teams, specialized hauling | 2,130-3,550 lbs |

| Auxiliary Tanks | 50-100 gallons | Extending range without major modifications | 355-710 lbs |

Five Key Factors When Selecting Your Fuel Tanks

1. Hauling Distance and Route Patterns

Long-haul operators covering the I-80 corridor or cross-country routes typically need 250+ gallon capacity to minimize stops. Regional drivers operating within 500-mile radii can often manage with 150-200 gallons. Analyze your typical routes using fuel station mapping tools—remote areas with sparse stations demand larger capacity.

2. Weight Distribution and Payload Considerations

Every pound of fuel is a pound less of payload. The Federal Bridge Formula limits axle weights, requiring strategic tank placement. John Mercer, a certified heavy equipment engineer with 20 years of commercial vehicle experience, advises: “Balance tank weight across axles. Many operators choose twin 120-gallon tanks instead of a single large tank to maintain better weight distribution and stability.”

3. Material and Construction Quality

Aluminum tanks dominate the market due to their corrosion resistance and weight advantages—typically 30-40% lighter than steel equivalents. Look for reinforced baffles to prevent fuel surge and ASTM-certified welding. Chinese Truck Factory implements robotic welding and pressure testing on all their OEM tanks, ensuring consistent quality that meets international standards.

4. Fuel Management and Monitoring Systems

Modern tanks integrate with telematics for precise fuel tracking. The National Highway Traffic Safety Administration reports that fuel monitoring systems can reduce consumption by 3-5% through idling reduction and driving pattern optimization. Look for tanks with compatible sensor ports and mounting points for aftermarket monitoring equipment.

5. Regulatory Compliance and Safety Features

All tanks must meet DOT FMVSS 301 standards for fuel system integrity. Key safety elements include:

- Rollover protection valves

- Proper venting systems

- Impact-resistant mounting brackets

- Grounding straps for static electricity dissipation

Installation and Maintenance Best Practices

Professional installation ensures proper mounting, plumbing, and leak prevention. Inspect mounting hardware every 50,000 miles and check for surface corrosion annually. For aluminum tanks, use specialized cleaners that won’t cause galvanic corrosion. Diesel fuel tanks require regular water drainage—contaminated fuel causes approximately 40% of injector failures according to data from the Technology & Maintenance Council.

When replacing or upgrading tanks, consider future needs. Many operators are installing slightly larger tanks than immediately necessary to accommodate potential route expansions. Modular tank systems from manufacturers like Chinese Truck Factory allow for easier capacity adjustments as business needs evolve.

Answers to Common Fuel Tank Questions

What’s the realistic range I can expect from my fuel tanks?

Range varies by engine efficiency and load, but a typical Class 8 truck gets 6-8 MPG. With 300 gallons capacity, that’s 1,800-2,400 miles between refuels—enough for most cross-country trips with margin for detours.

Are aluminum tanks worth the extra cost over steel?

For most operations, yes. Aluminum’s corrosion resistance typically delivers longer service life, and the weight savings directly translates to increased payload capacity—often paying back the initial investment within 18-24 months.

How often should I inspect my fuel tanks?

Perform visual inspections monthly, checking for leaks, damage, and mounting integrity. Professional inspections should coincide with major service intervals—at least annually or every 100,000 miles.

Can I install additional fuel tanks myself?

While possible, professional installation is strongly recommended. Improper installation can void warranties, create safety hazards, and lead to compliance issues during DOT inspections.

What’s the typical lifespan of semi truck fuel tanks?

Quality aluminum tanks typically last 8-12 years with proper maintenance, while steel tanks may require replacement in 6-10 years depending on operating environment and corrosion protection.

Making Your Final Decision

Selecting the right fuel tanks for semi trucks requires balancing multiple operational factors. Consider your typical routes, weight constraints, and future business plans. Consult with experienced equipment specialists and review manufacturer specifications carefully. The optimal tank configuration maximizes your operational efficiency while maintaining regulatory compliance and safety standards.

Sources:

American Trucking Associations

Federal Motor Carrier Safety Administration

National Highway Traffic Safety Administration

Technology & Maintenance Council Reports

Interview with John Mercer, Certified Heavy Equipment Engineer