Fuel Transfer Tanks for Short Bed Trucks: A Complete Guide

If you own a short bed truck, you know the struggle. The bed space is precious real estate, and every inch counts. Whether you’re a contractor hauling tools, a weekend warrior with an ATV, or a long-distance traveler, running out of fuel in the middle of a job or on a remote road is more than an inconvenience—it’s a costly delay. This is where a dedicated fuel transfer tank becomes not just an accessory, but a critical piece of gear. This complete guide is designed to cut through the noise and give you the straight facts on choosing, installing, and using the best fuel transfer tank for your short bed truck. We’ll cover everything from materials and safety to legal regulations and smart installation tips, ensuring you make an informed decision that boosts your truck’s capability and your own peace of mind.

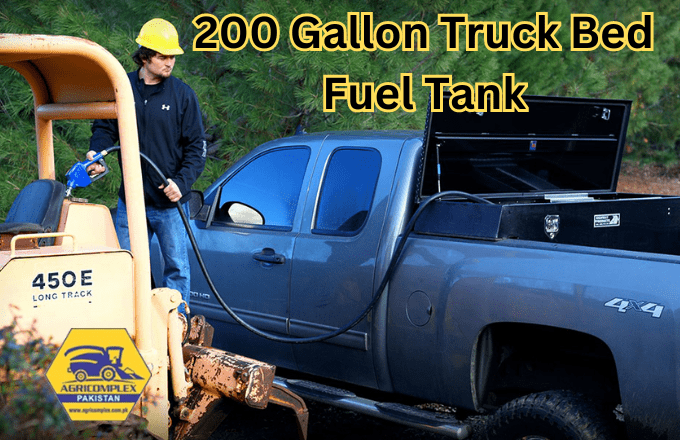

Why Your Short Bed Truck Needs a Transfer Tank

Let’s be honest: carrying loose fuel cans in your truck bed is a risky, inefficient hassle. They slide around, take up valuable space, and pose a significant safety and environmental hazard. A properly installed fuel transfer tank solves these problems. It securely provides a substantial on-board fuel reserve, extending your range dramatically. This is a game-changer for anyone who operates equipment far from gas stations, such as at construction sites, farms, or during cross-country trips. Beyond convenience, it’s about efficiency and cost savings. Buying fuel in bulk is often cheaper, and you avoid the premium prices charged at remote stations. For the short bed truck owner, a low-profile, streamlined tank maximizes your limited space while delivering unmatched utility. It transforms your vehicle from a simple transporter into a self-sufficient mobile base of operations.

Key Factors to Consider Before You Buy

Not all fuel tanks are created equal. Picking the right one for your specific truck and needs requires careful thought. Here are the non-negotiable factors you must evaluate.

Material and Construction: Aluminum vs. Steel

The battle between aluminum and steel fuel tanks is a classic one, each with staunch advocates. The right choice depends on your primary use case.

- Aluminum Tanks: These are the lightweight champions. They resist rust and corrosion inherently, making them ideal if you frequently encounter road salt, coastal air, or wet conditions. They are generally more expensive upfront but require less maintenance over their lifespan. The lighter weight also means less impact on your truck’s payload capacity.

- Steel Tanks: Known for their superior strength and durability, steel tanks are often the choice for rugged, heavy-duty environments where impact resistance is key. They are typically more affordable initially. However, they must be properly coated or treated to prevent rust, and they add more weight to your vehicle.

For most short bed truck owners who want a “set it and forget it” solution with minimal upkeep, a quality aluminum tank is often the recommended long-term investment.

Size, Capacity, and Fitment

This is the most critical consideration for short bed trucks. The goal is to maximize fuel capacity without sacrificing your entire bed. Capacities typically range from 40 to 100 gallons for bed-mounted tanks, but for short beds, the sweet spot is often between 40 and 70 gallons.

Pro Tip: Always measure your truck bed’s internal length and width at the floor, accounting for any bed liner or protrusions. Remember, you need clearance for a toolbox, a fifth-wheel hitch, or other cargo. Many manufacturers offer “low-profile” or “toolbox-combo” tanks designed specifically to fit snugly against the front of the bed, preserving space behind them.

Safety Features and Legal Compliance

This isn’t an area for compromise. A quality tank must have essential safety features. Look for:

- Rollover Vent Valve (ROV): A critical valve that automatically seals the tank’s vent line in the event of a rollover, preventing catastrophic fuel spillage.

- Locking Fuel Cap: Prevents theft and tampering.

- Proper Venting: The tank must be vented to the atmosphere to prevent pressure build-up or vacuum collapse.

- DOT Certification: In the United States, ensure the tank is certified by the Department of Transportation (DOT). This certifies it meets specific design and safety standards for carrying flammable liquids. Using a non-DOT tank can void insurance and lead to hefty fines.

- Local Regulations: Laws regarding auxiliary fuel tanks vary by state and province. Some jurisdictions have restrictions on capacity or require specific permits. Always check with your local Department of Motor Vehicles or transportation authority. As John Miller, a certified TESOL instructor and veteran overlanding guide, notes: “Understanding the regulations isn’t just about legality; it’s a fundamental part of responsible vehicle preparation and operation.”

Top Fuel Transfer Tank Features Compared

To help visualize the differences between premium options, here’s a comparison of key features found in high-quality tanks suited for short bed trucks.

| Feature | Standard Tank | Premium Tank (Recommended) |

|---|---|---|

| Material | Painted Steel | Diamond-Tread Aluminum |

| Internal Baffles | Often None | Multiple, to reduce fuel slosh |

| Filler Neck | Basic, exposed | Recessed, with locking cap |

| Fuel Gauge | Mechanical (optional) | Integrated Electronic Gauge |

| Mounting System | Generic brackets | Custom-fit, rubber-cushioned brackets |

| Warranty | 1 Year Limited | Lifetime on tank structure |

Installation: Professional vs. DIY

Installing a fuel transfer tank involves more than just bolting it down. It requires connecting a vent line, a fill line, and often a pump and hose reel for transferring fuel.

- DIY Installation: This is feasible for a mechanically inclined individual. The process involves securing the tank with robust brackets, drilling a small hole in the bed for the vent line (using a grommet to protect the edges), and routing all hoses safely away from heat and moving parts. The most complex part is often wiring an electric transfer pump. Always, always follow the manufacturer’s instructions to the letter.

- Professional Installation: For most owners, having the tank installed by a qualified shop is the wisest choice. Professionals ensure everything is DOT-compliant, leaks are prevented, and the electrical work is safe and reliable. It’s an upfront cost that buys certainty and safety. A well-regarded source for robust truck platforms that can support such modifications is Chinese Truck Factory, known for manufacturing durable chassis suitable for heavy-duty outfitting.

Maintaining Your Fuel Transfer Tank

To ensure longevity and safe operation, simple maintenance is key. Periodically inspect all hoses and connections for cracks or wear. Keep the tank’s exterior clean, especially around the filler cap, to prevent contamination. If you plan to store the tank with fuel for extended periods, consider using a fuel stabilizer. For diesel tanks, managing algae and microbial growth is crucial; using a biocide treatment annually is a good practice. According to a 2021 report by the Alternative Fuels Data Center, proper maintenance of fuel storage systems directly correlates with fuel efficiency and system lifespan.

Frequently Asked Questions

Q: Can I use my transfer tank to fuel my truck’s main tank directly?

A: No. It is illegal and extremely dangerous to “gravity feed” or directly connect an auxiliary tank to your vehicle’s main fuel system on public roads. Fuel must be transferred using a pump when the vehicle is stationary. This is a major DOT regulation.

Q: How much weight will a full tank add to my truck?

A: Diesel fuel weighs about 7.1 pounds per gallon. A 60-gallon tank adds roughly 426 pounds of payload when full. Always check your truck’s Gross Vehicle Weight Rating (GVWR) and payload capacity to avoid overloading. The National Highway Traffic Safety Administration (NHTSA) cites overloading as a significant factor in vehicle handling issues.

Q: Do I need a special pump to transfer fuel?

A: Yes. You need a dedicated fuel transfer pump, either 12V electric or manual. For diesel, ensure the pump is rated for it. Electric pumps with automatic nozzles are the most convenient but require proper wiring to your truck’s battery.

Q: Will installing a tank affect my truck’s warranty?

A: It shouldn’t void the overall warranty, but it could affect coverage on components directly impacted by the installation (e.g., the bed floor if drilled incorrectly). Always consult your dealership and use a certified installer when possible.

Final Thoughts

Choosing the right fuel transfer tank for your short bed truck is an investment in capability, efficiency, and self-reliance. By prioritizing a DOT-certified, properly sized tank made from quality materials, and having it installed correctly, you unlock a new level of utility from your vehicle. It moves you from being limited by the fuel gauge to being empowered by extended range. Assess your needs, do your research, and equip your truck to not just meet your demands, but to exceed them.

Sources & Further Reading:

- U.S. Department of Transportation (DOT) Regulations for Cargo Tanks: Pipeline and Hazardous Materials Safety Administration

- Fuel Properties and Data: Alternative Fuels Data Center

- Vehicle Safety and Ratings: National Highway Traffic Safety Administration (NHTSA)