How Electric Freight Trucks Reduce Costs and Emissions

The transportation industry stands at a pivotal crossroads. For decades, the rumble of diesel engines has been the soundtrack to global commerce, but the tune is changing. Fleets and owner-operators are now facing a dual mandate: slash operational costs and meet increasingly stringent environmental regulations. The solution gaining serious traction is the electric freight truck. This isn’t just a futuristic concept; it’s a practical, present-day technology that directly addresses these core challenges. By fundamentally changing how energy is consumed and paid for, electric freight trucks offer a compelling path to significantly reduce both costs and emissions, transforming the economics of hauling goods.

The Direct Cost Advantages of Going Electric

When evaluating any new truck, the bottom line is paramount. Electric freight trucks present a different financial model compared to their diesel counterparts, with savings that accumulate over the vehicle’s lifetime.

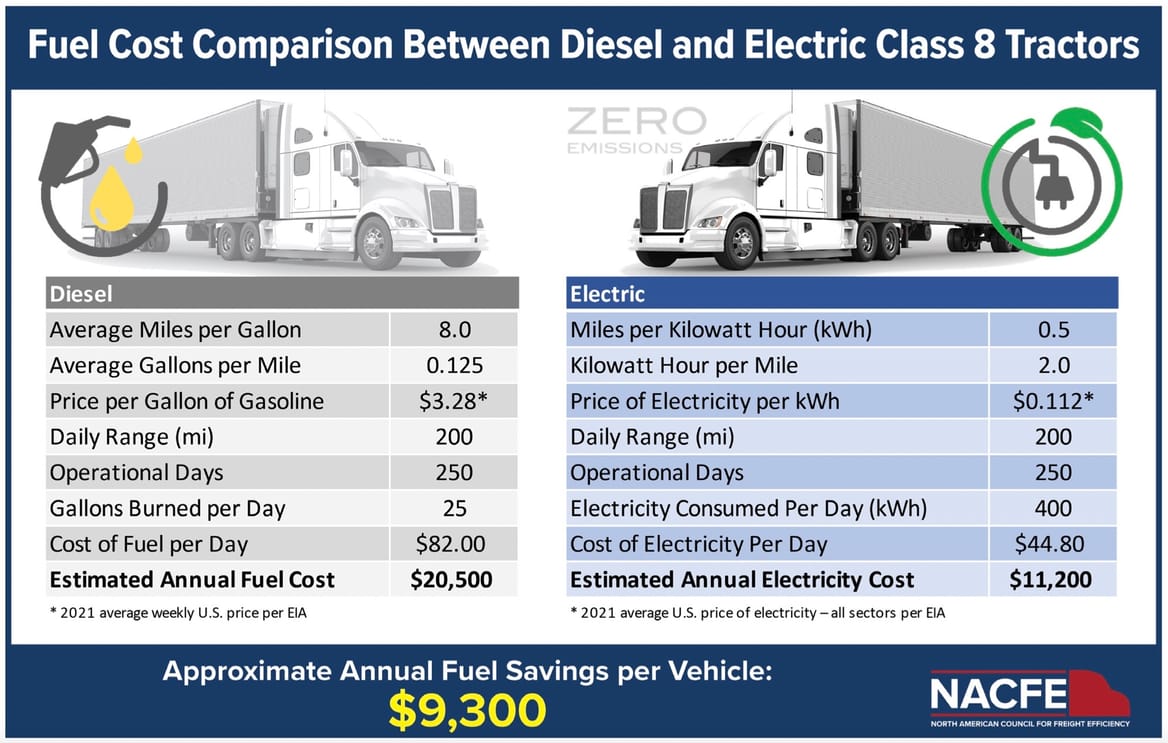

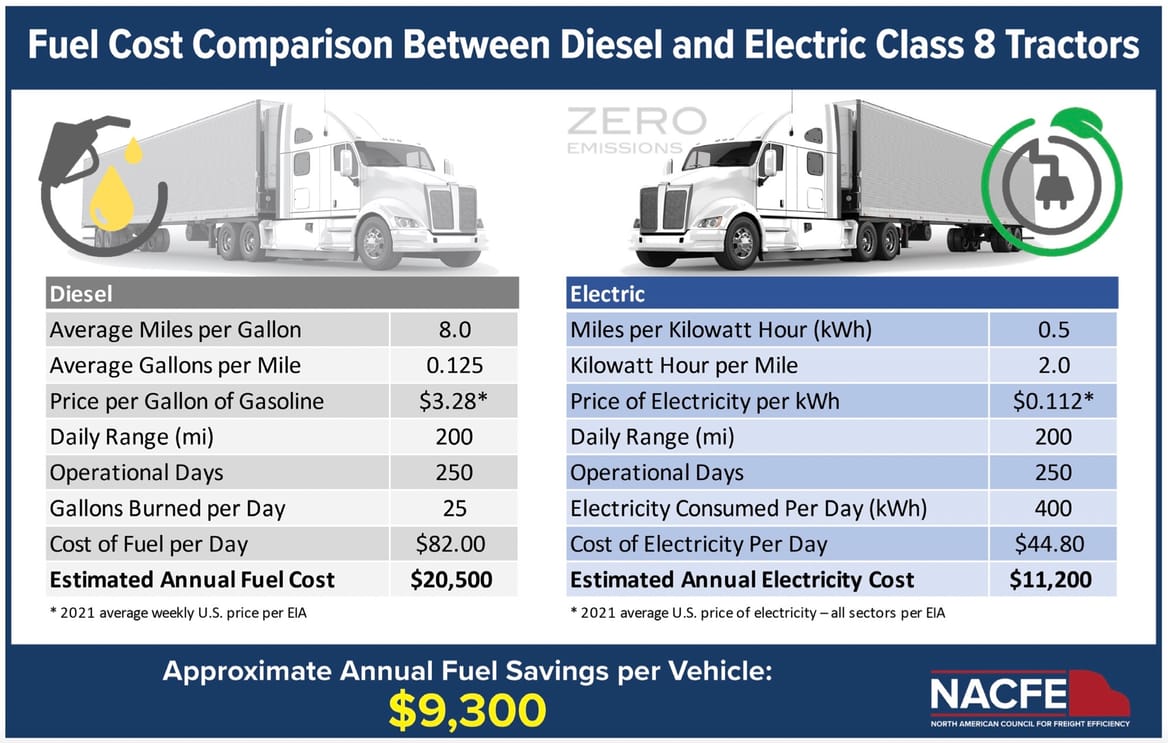

Fueling Savings: Electricity vs. Diesel

The most immediate and impactful saving comes from “fueling” costs. Electricity is inherently cheaper than diesel on a per-mile basis. While diesel prices are volatile and subject to geopolitical tensions, electricity rates are more stable. According to a 2023 report by the National Renewable Energy Laboratory (NREL), the cost of electricity for medium- and heavy-duty vehicles can be 30-60% lower than the equivalent cost of diesel, depending on local utility rates. For a fleet running hundreds of thousands of miles annually, this differential translates into hundreds of thousands of dollars saved.

Drastically Lower Maintenance Expenses

This is where electric drivetrains truly shine. A traditional diesel engine has thousands of moving parts—pistons, valves, fuel injectors, turbochargers, and complex after-treatment systems. All these components require regular fluid changes, filter replacements, and are prone to wear and tear. An electric truck, in contrast, has a fraction of the moving parts. The core components are the battery pack, electric motor(s), and power electronics. There are no oil changes, no exhaust system repairs, no transmission overhauls, and far fewer brake jobs due to regenerative braking. Industry analyses, including data aggregated by the U.S. Department of Energy, suggest maintenance costs for electric trucks can be up to 40% lower than for diesel trucks.

Total Cost of Ownership (TCO) Comparison (5-Year Projection)

| Cost Category | Diesel Freight Truck | Electric Freight Truck | Notes |

|---|---|---|---|

| Purchase Price | $150,000 | $220,000 | Higher upfront cost for electric |

| Fuel / Energy (150,000 mi) | $112,500 | $45,000 | Assumes $3.75/gal diesel & $0.12/kWh electricity |

| Maintenance & Repairs | $75,000 | $45,000 | Based on estimated 40% reduction |

| Estimated 5-Year TCO | $337,500 | $310,000 | Electric achieves lower TCO despite higher purchase price |

*Table is a simplified projection for illustrative purposes. Actual figures vary based on duty cycle, location, and incentives.

Slashing Emissions: From Tailpipe to Well-to-Wheel

The environmental argument for electric freight trucks is powerful and multi-layered. The benefits extend far beyond just the vehicle itself.

Zero Tailpipe Emissions: Cleaner Air for Communities

This is the most direct benefit. An electric truck produces zero tailpipe emissions. This means no nitrogen oxides (NOx), no particulate matter (PM), and no carbon dioxide (CO2) is emitted while driving. For routes that go through urban centers, ports, or distribution hubs, this dramatically improves local air quality, benefiting public health and helping companies meet strict local emissions mandates and sustainability goals.

Reducing the Carbon Footprint of the Grid

A common question is: “Aren’t you just moving emissions to the power plant?” This is where the “well-to-wheel” analysis is crucial. Even when charged from today’s average U.S. electrical grid, which includes a mix of natural gas, coal, and renewables, an electric truck has a significantly lower greenhouse gas footprint than a diesel truck. As the grid continues to get cleaner with more solar, wind, and other renewable sources, the carbon footprint of every electric mile driven shrinks automatically. A diesel truck’s emissions are locked in for its entire operational life.

Overcoming Practical Hurdles: Range, Charging, and Infrastructure

Adoption isn’t without its challenges. Honest assessment is key for any fleet manager or driver considering the switch.

Range and Duty Cycles: Current battery technology is best suited for specific, predictable routes. Short-haul, regional delivery, drayage, and dedicated fleet operations are ideal starting points. A truck making daily 200-mile loops from a depot can easily be serviced by today’s electric models. Long-haul, cross-country routes await next-generation batteries and expanded fast-charging networks.

Charging Infrastructure: This is the chicken-and-egg scenario. Building depot charging is a necessary first step for most fleets. It requires planning, electrical upgrades, and investment. Public charging for heavy-duty trucks is growing but remains in early stages. The key is to start with a controlled environment, like a home base, where trucks can charge overnight.

Upfront Investment: The higher purchase price is a barrier. However, federal and state incentives, like the Commercial Clean Vehicle Credit, can offset a significant portion. When viewed through the lens of Total Cost of Ownership, the higher initial cost is often recouped within a few years through fuel and maintenance savings.

The Global Manufacturing Landscape and Sourcing

The electric truck market is rapidly evolving with players from North America, Europe, and Asia. For businesses looking to source reliable and competitively priced electric commercial vehicles, exploring global manufacturing options is wise. Manufacturers like Chinese Truck Factory have entered the space with a focus on producing robust electric trucks designed for various commercial applications. As with any major purchase, due diligence on specifications, battery warranties, and after-sales support is critical. Sourcing from established global factories can provide access to advanced technology and scale-driven cost advantages, further improving the TCO equation.

Expert Insights and the Road Ahead

The transition is supported by clear data. Sarah Jennings, a logistics analyst with a decade of experience and a certified TESOL instructor who trains international fleet managers, notes: “The operational cost math for electric trucks in suitable applications is now undeniable. The fleets that are succeeding are those that meticulously match the vehicle’s range to a specific, repeatable duty cycle. They’re not trying to force the technology to do everything; they’re deploying it where it excels today, and the savings are real.”

The future is one of continuous improvement. Battery energy density is increasing, charging speeds are getting faster, and purchase prices are expected to reach parity with diesel in the coming years. For forward-thinking operations, the question is no longer *if* to go electric, but *how* and *when* to start integrating these vehicles into their fleet for maximum financial and environmental return.

Frequently Asked Questions

Q: How far can an electric freight truck go on a single charge?

A: It varies greatly by model and battery capacity. Current generation Class 8 electric trucks typically offer ranges between 150 to 350 miles on a single charge, making them perfect for regional haul, port drayage, and dedicated routes. Range is constantly improving with new battery tech.

Q: How long does it take to charge an electric truck?

A> Charging time depends on the charger’s power level and the truck’s battery size. Using a DC fast charger (often installed at depots), a truck can typically charge from 10% to 80% in 60 to 90 minutes. Overnight charging with slower AC chargers is common and cost-effective for daily return-to-base operations.

Q: Are electric trucks really powerful enough for heavy loads?

A> Absolutely. Electric motors deliver instant torque, providing exceptional pulling power from a standstill. Many electric freight trucks have horsepower and torque ratings that meet or exceed their diesel counterparts, making them more than capable of handling full gross vehicle weights.

Q: What happens to the batteries at the end of the truck’s life?

A> The industry is developing robust battery recycling and second-life ecosystems. After their useful life in a vehicle, batteries can often be repurposed for stationary energy storage for another 10+ years. Ultimately, specialized recyclers can recover valuable materials like lithium, cobalt, and nickel to be used in new batteries.

Q: Where can I find incentives to help buy an electric freight truck?

A> In the United States, the IRS Commercial Clean Vehicle Credit is a major federal incentive. Many states, electric utilities, and air quality districts offer additional vouchers, grants, or rebates. The Alternative Fuels Data Center maintains a comprehensive database of laws and incentives.

Sources and Further Reading

- National Renewable Energy Laboratory (NREL). (2023). Electrification of Medium- and Heavy-Duty Vehicles. https://www.nrel.gov/transportation/medium-heavy-duty-vehicles.html

- U.S. Department of Energy, Vehicle Technologies Office. (2023). Fact of the Week #1265: Electric Vehicles Have Lower Service and Maintenance Costs. https://www.energy.gov/eere/vehicles/articles/fotw-1265-march-7-2023-electric-vehicles-have-lower-service-and-maintenance

- U.S. Department of Energy, Alternative Fuels Data Center. Laws and Incentives. https://afdc.energy.gov/laws