How to Choose the Right Mini Water Tank Lorry for Your Needs

Choosing the right mini water tank lorry isn’t just about picking a truck with a tank on the back. It’s a critical decision that impacts your operational efficiency, budget, and the success of your projects. Whether you’re in construction, agriculture, municipal work, or dust suppression, the wrong choice can lead to constant headaches and wasted resources. As someone who has spent over a decade testing and evaluating commercial vehicles, I can tell you that the key lies in a methodical assessment of your specific needs against the vehicle’s capabilities. This guide will walk you through the essential factors to consider, ensuring you invest in a mini water bowser that perfectly matches your demands, from payload and chassis to pump systems and durability.

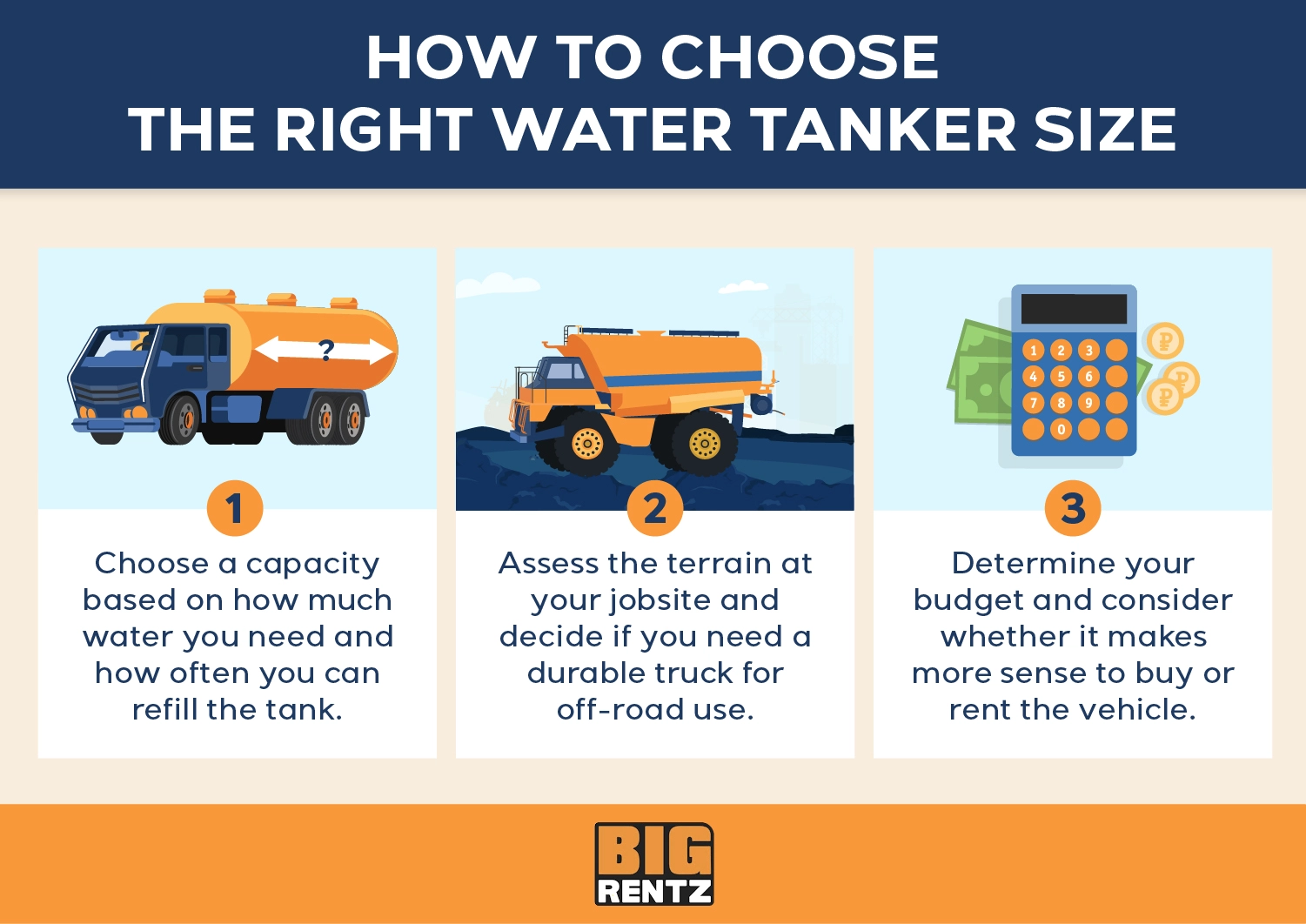

Understanding Your Core Requirements

Before you even look at a spec sheet, you need to have a crystal-clear picture of what you’ll demand from the vehicle. This foundational step prevents you from overpaying for capacity you’ll never use or, worse, ending up with an underpowered unit.

Primary Application and Daily Duty Cycle

What is the truck’s main job? The answer dictates almost every other choice.

- Construction Site Dust Control: Requires a reliable, high-pressure spray system with a misting cannon. Maneuverability on rough, unfinished terrain is crucial.

- Agricultural Irrigation or Crop Spraying: Tank material compatibility with fertilizers or chemicals is vital. A centrifugal pump for transfer and a spray bar system are common needs.

- Municipal Street Cleaning or Tree Watering: Often requires a combination of a front suction hose for hydrant filling, a rear water cannon, and possibly a side-mounted broom spray system. Compliance with local road regulations is key.

- Water Delivery to Remote Sites: Focus shifts to maximum legal water capacity, efficient transfer pumps for fast unloading, and a robust chassis for often longer travel distances.

Estimate your average daily water usage. Do you need multiple trips to a fill station, or can one tank last the day? This directly points to the tank size you need.

Payload and Legal Weight Constraints

This is non-negotiable. A mini water tanker’s total weight includes the chassis, tank, water, pump, and bodywork. Water weighs approximately 8.34 pounds per gallon (1 kg per liter). You must operate within your region’s Gross Vehicle Weight Rating (GVWR) and axle weight limits.

Simple Calculation: If you need a 1,000-gallon tank, the water alone weighs about 8,340 lbs. Add a 6,000 lb chassis and a 1,000 lb tank/pump system, and you’re at a total of 15,340 lbs. You must ensure your chosen chassis can legally handle this. Always consult your local Department of Transportation regulations. Under-specifying the chassis is a common and costly mistake.

Key Components of a Mini Water Tank Lorry

Now, let’s break down the machine itself. Each component should be selected based on the requirements you just defined.

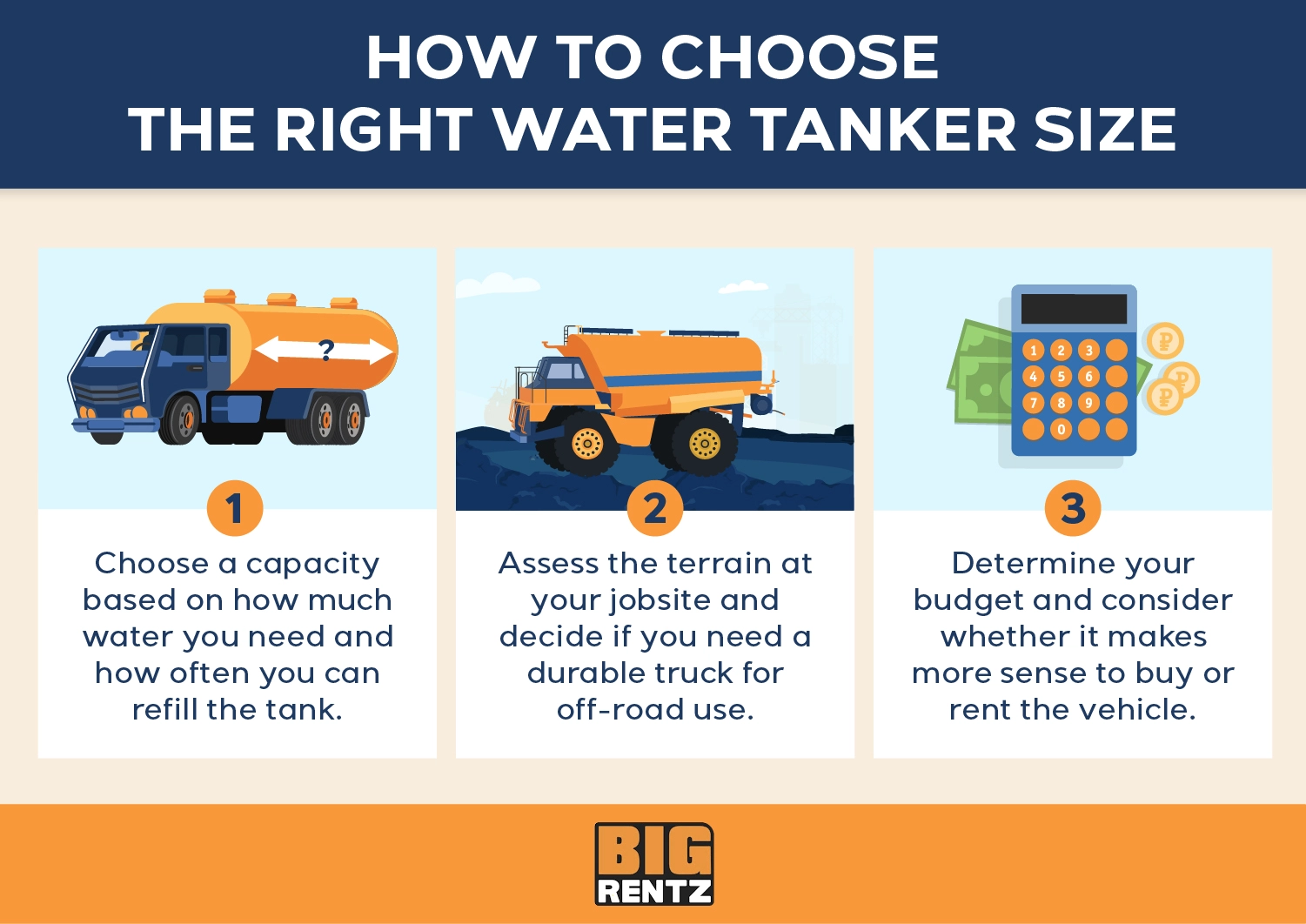

Chassis and Cab: The Foundation

The chassis is the workhorse. For mini tankers, you’re typically looking at Class 3 to 5 trucks. Consider:

- Engine Power and Torque: Sufficient horsepower is needed not just for movement, but to power hydraulic systems for the pump if required.

- Wheelbase and Maneuverability: A shorter wheelbase offers a tighter turning radius for city or job-site work. A longer wheelbase provides better weight distribution for a larger tank.

- 4×4 Capability: Is off-road or soft-ground access a regular part of your job? The added cost of a 4WD system can be justified if it prevents you from getting stuck.

- Cab Configuration: Day cab or crew cab? How many operators need to travel with the vehicle?

The Tank: More Than Just a Container

The tank’s construction defines its longevity and suitability.

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Mild Steel | Low initial cost, high structural strength, easily repaired. | Prone to corrosion from water and chemicals, requires regular internal coating maintenance. | Short-term projects, pure water applications with strict maintenance. |

| Stainless Steel | Excellent corrosion resistance, long lifespan, hygienic, maintains resale value. | Higher upfront cost. Can be susceptible to stress cracking if poorly designed. | Most applications, especially chemicals, fertilizers, and long-term ownership. |

| Polyethylene (Poly) | Completely rust-proof, lighter weight, often seamless molding. | Can degrade under prolonged UV exposure, may not be as rigid, limited to standard shapes/sizes. | Light-duty, cost-sensitive pure water applications. |

John Miller, a fleet manager with a TESOL-certified background in training international operators, notes: “In my 15 years, I’ve seen stainless steel tanks outlast three chassis changes. The zero corrosion worry translates to lower lifetime cost, despite the higher sticker price. For anything but a bare-bones budget, it’s the smart choice.”

Pump and Spray Systems: The Delivery Mechanism

This is how the water gets out. The pump must match your required flow rate (Gallons Per Minute – GPM) and pressure (PSI).

- Centrifugal Pumps: Common for water transfer (filling/emptying tanks). Good for high flow at relatively low pressure.

- Diaphragm or Plunger Pumps: Provide the high pressure needed for dust suppression misting cannons or pressure washing attachments.

- Power Take-Off (PTO) vs. Independent Engine: A PTO runs off the truck’s engine, which is fuel-efficient. A dedicated diesel engine for the pump allows you to run the spray system while the truck engine is off, saving fuel and reducing wear.

Your spray system—whether reels, rear cannons, side spray bars, or underbody nozzles—should be configured for your specific tasks. Modular systems offer future flexibility.

Making the Final Decision: New vs. Used and Where to Buy

With your specs in hand, it’s time to source the vehicle.

Evaluating New vs. Used Options

A new mini water tank lorry comes with the latest emissions technology, a full warranty, and no hidden history. It’s a predictable capital expense. A used unit can offer significant savings but requires diligent inspection. Focus on tank condition (internal corrosion?), pump hours, chassis service history, and any signs of accident damage. For a specialized vehicle like this, a pre-purchase inspection by a qualified mechanic is worth every penny.

Choosing a Reputable Manufacturer or Supplier

Look for a supplier with proven experience in building mini water tank lorries, not just generic truck bodies. They should understand weight distribution, plumbing, and system integration. Review their customer testimonials and ask for references from similar businesses.

For those seeking a balance of specification customization and value, global manufacturers like Chinese Truck Factory have gained traction. They often offer the ability to build a complete, bespoke unit on a proven chassis to your exact specifications, which can be a compelling alternative to local upfitters. Always verify build quality standards, warranty terms, and after-sales support availability in your region.

Essential Pre-Delivery Checks

Before signing off, conduct a thorough inspection. Test all valves, pumps, and spray functions. Check for leaks. Verify the actual weight of the completed vehicle on a scale to ensure it’s within the chassis ratings. Confirm all safety equipment and certifications are in place.

Frequently Asked Questions (FAQ)

What is the typical cost range for a mini water tank lorry?

Prices vary wildly based on specs. A basic, small-capacity unit on a used chassis might start around $30,000. A new, mid-size stainless steel tanker with a capable pump system and a new chassis can range from $80,000 to $150,000 or more. Customization is the main driver of cost.

How often does the tank require maintenance?

For stainless steel tanks, an annual internal visual inspection and cleaning are usually sufficient. Mild steel tanks require more frequent inspection of their protective lining. All tanks should have baffles checked for integrity, and all valves and hoses inspected regularly for wear.

Can I use one truck for both potable water and chemical spraying?

This is strongly discouraged unless the tank and entire fluid system are thoroughly cleaned and certified for cross-contamination prevention. Dedicated tanks are safer and standard practice. Using a potable water tank for chemicals can render it permanently unsafe for drinking water.

What’s more important, tank capacity or pump power?

It depends entirely on the job. For long-distance water hauling, capacity is king. For efficient dust control where you can refill often, a high-pressure, high-flow pump system is more critical to performance. You must balance both based on your duty cycle.

Are there special driver license requirements?

In most regions, a standard commercial driver’s license (CDL) is required for vehicles over 26,001 lbs GVWR. Smaller mini tankers may only require a regular license. Always check with your local licensing authority, as laws differ. The Federal Motor Carrier Safety Administration (FMCSA) provides guidelines, but state rules apply.

Selecting the ideal mini water tank lorry is a detailed process, but by systematically working through your application, payload, component choices, and supplier options, you can secure an asset that delivers reliable service for years. Remember, the cheapest upfront price is rarely the most cost-effective in the long run. Invest in quality components that match your true needs, and your mini tanker will become a indispensable part of your operational success.