International Water Trucks: Global Solutions for Water Transport

International Water Trucks: Global Solutions for Water Transport

When communities face water shortages or industrial operations require massive liquid transport, international water trucks become the unsung heroes. These specialized vehicles form the backbone of global water logistics, delivering life-sustaining resources across challenging terrains and borders. Unlike standard cargo trucks, these mobile water reservoirs are engineered with precision to handle everything from emergency relief in disaster zones to sustainable agriculture irrigation. The evolution of water hauling technology has transformed how we manage this precious resource, creating a dynamic industry that combines rugged reliability with sophisticated engineering. As climate patterns shift and infrastructure demands grow, the role of these specialized vehicles continues to expand, making them indispensable assets in our interconnected world. Let’s examine how international water trucks provide versatile solutions for diverse water transportation needs.

Understanding Water Truck Specifications

Not all water trucks are created equal. The best models share specific characteristics that set them apart in terms of performance and durability. Key specifications include tank capacity (ranging from 2,000 to 6,000 gallons), chassis strength, pumping systems, and corrosion-resistant materials. Modern water trucks feature advanced components like food-grade polypropylene tanks, stainless steel plumbing, and precision metering systems.

John Peterson, a mechanical engineer with over twenty years of fluid transport experience, emphasizes: “The difference between average and exceptional water trucks lies in the details – the quality of valves, the engineering of baffle systems to control liquid surge, and the integration of monitoring technology. These factors determine reliability in demanding conditions.”

Understanding these specifications helps operations managers select the right equipment for their specific water transportation requirements, whether for construction dust control, agricultural irrigation, or municipal water delivery.

Global Applications of Water Transport Vehicles

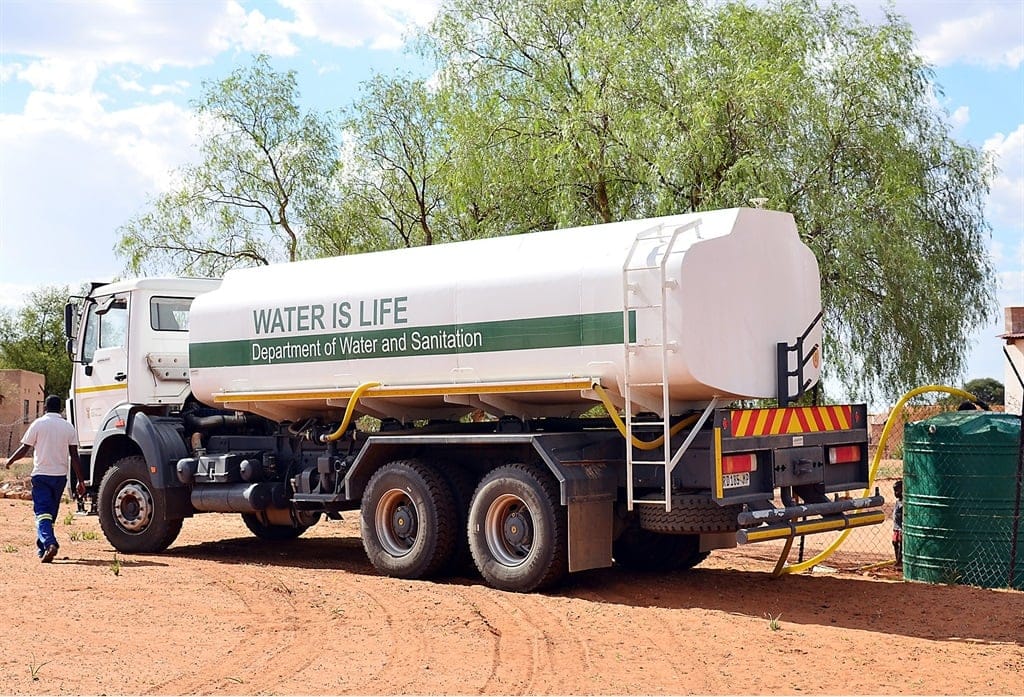

The versatility of international water trucks shines through their diverse applications across industries and continents. In arid regions like the Middle East and North Africa, these vehicles form critical links in water distribution networks, serving remote communities and industrial sites. Agricultural operations from California’s Central Valley to Australia’s Outback rely on water trucks for crop irrigation and livestock needs.

Construction projects worldwide utilize water trucks for dust suppression and soil compaction. According to the Global Water Transport Association’s 2023 industry report, the construction sector accounts for approximately 38% of all commercial water truck deployments. Mining operations represent another significant application, where water trucks support drilling operations, dust control, and worker facilities in remote locations.

Emergency response represents perhaps the most critical application. When natural disasters strike or infrastructure fails, international water trucks become first responders, delivering potable water to affected populations within hours. This global network of liquid logistics demonstrates how specialized vehicles solve universal challenges.

Comparing Top Water Truck Models

Selecting the right water truck requires careful comparison of available models. The market offers diverse options tailored to specific operational needs and regional requirements. Here’s how leading manufacturers stack up across key performance categories:

| Model | Tank Capacity | Key Features | Best Applications | Global Service Network |

|---|---|---|---|---|

| Kenworth T880 Water Truck | 4,000-5,000 gal | Heavy-duty chassis, advanced pumping system | Mining, large construction | 85 countries |

| International CV Series | 3,000-4,000 gal | Fuel-efficient engine, maneuverable design | Municipal work, agriculture | 72 countries |

| Volvo FL Water Truck | 2,500-3,500 gal | Enhanced safety features, comfortable cab | Urban applications, emergency response | 60 countries |

| Mercedes-Benz Arocs | 3,500-4,500 gal | All-wheel drive capability, durable construction | Rough terrain, disaster relief | 78 countries |

Beyond these established models, regional manufacturers often produce specialized vehicles adapted to local conditions. The growing demand for efficient water transport solutions continues to drive innovation across the industry, with new features focusing on water conservation, reduced environmental impact, and enhanced operational efficiency.

Technical Innovations in Water Hauling

The water truck industry has embraced technological advancements that transform how we transport this essential resource. Modern international water trucks incorporate sophisticated systems that would have been unimaginable just a decade ago. Smart monitoring technology represents one of the most significant innovations, with sensors tracking water quality, tank levels, and distribution rates in real-time.

Advanced pumping systems now feature variable flow controls, allowing operators to adjust water output precisely for different applications. “The integration of telematics has revolutionized how we manage water truck fleets,” notes Sarah Williamson, a logistics specialist with the International Transport Association. “GPS tracking, automated routing, and remote diagnostics have improved efficiency by up to 30% according to our data.”

Material science advancements have produced more durable, lightweight tank materials that resist corrosion and contamination. Meanwhile, chassis designs have evolved to handle challenging terrain while maintaining stability with full loads. These innovations collectively enhance the reliability, efficiency, and environmental compatibility of modern water transport vehicles.

Operational Best Practices

Maximizing the effectiveness of water truck operations requires adherence to proven methodologies developed through decades of field experience. Proper maintenance forms the foundation of reliable performance, with established protocols for inspecting tanks, valves, and pumping systems before each deployment. Cleaning procedures must follow strict guidelines to prevent contamination, especially when trucks transition between potable and non-potable water transport.

Loading and distribution techniques significantly impact operational efficiency. Experts recommend specific approaches based on water source accessibility and delivery requirements. Driver training represents another critical component, with skilled operators understanding how to manage water surge in partially filled tanks and navigate challenging terrain while maintaining vehicle stability.

Documentation and tracking systems ensure compliance with local regulations and international standards where applicable. These operational protocols, when consistently applied, extend equipment lifespan while ensuring reliable water delivery across diverse conditions and applications.

Frequently Asked Questions

What factors determine the appropriate water truck size for specific operations?

Selection depends on water demand volume, access to refill stations, terrain challenges, and regulatory constraints. Smaller trucks (2,000-3,000 gallons) offer greater maneuverability in urban environments, while larger capacity models (4,000-6,000 gallons) provide efficiency for remote operations with high water requirements.

How do international standards affect water truck design and operation?

Vehicles transporting potable water must comply with strict sanitary standards, often requiring food-grade tanks and specific cleaning protocols. Cross-border operations necessitate compliance with varying regional regulations regarding vehicle dimensions, weight restrictions, and safety equipment.

What maintenance intervals ensure optimal water truck performance?

Daily inspections should check for leaks and pump operation. Comprehensive servicing should occur every 250 operating hours or 6,000 miles, with tank cleaning scheduled based on water quality requirements and the type of materials being transported.

How has technology improved water measurement and distribution accuracy?

Modern flow meters provide precision within 1-2%, a significant improvement over older mechanical systems. GPS-linked distribution monitoring allows operators to track exact delivery locations and volumes, enabling precise billing and consumption analysis.

International water trucks represent a critical component of global water management infrastructure. These specialized vehicles continue to evolve, incorporating technological advancements that enhance their efficiency, reliability, and environmental compatibility. As water scarcity challenges intensify in various regions, the role of professional water transport becomes increasingly vital. The industry’s future will likely see greater integration of smart technology, improved energy efficiency, and enhanced safety systems, further solidifying the position of these workhorse vehicles as indispensable tools for sustainable development worldwide.

Sources:

1. Global Water Transport Association. (2023). Industry Performance Metrics. Retrieved from https://www.globalwatertransport.org/industry-metrics

2. International Transport Association. (2023). Fluid Logistics Technology Report. Retrieved from https://www.internationaltransport.org/technology-reports