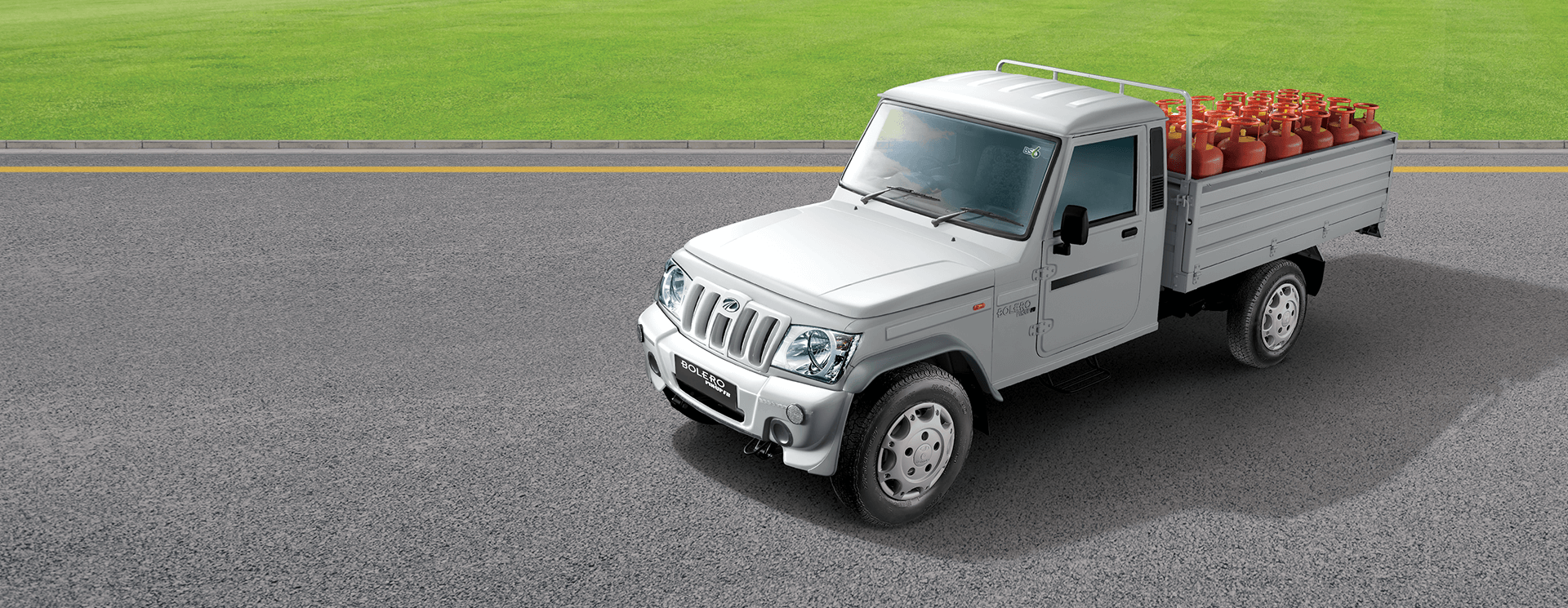

Mahindra Pickup Water Tanker: Features & Buying Guide

If you’re in the market for a robust, reliable, and purpose-built vehicle for water transportation, the Mahindra pickup water tanker is a compelling option that deserves a close look. Whether for agricultural irrigation, construction site dust control, or municipal water supply in remote areas, these versatile trucks are engineered to handle tough jobs. This comprehensive guide will walk you through the key features, specifications, and crucial buying considerations for a Mahindra water bowser. We’ll cut through the marketing speak and give you the practical insights you need to make an informed decision, ensuring your investment delivers maximum value and reliability for years to come.

Core Features and Build Quality of Mahindra Water Tankers

Mahindra pickup trucks are renowned for their rugged chassis and dependable diesel engines, which form the perfect foundation for a water tanker conversion. Unlike a standard pickup, a dedicated water tanker is a integrated system where the chassis, powertrain, and tank work in harmony.

Chassis and Powertrain: The Backbone

The durability starts with a reinforced ladder-frame chassis, designed to bear the significant weight of a full water tank without sagging or stress. Most conversions use models like the Mahindra Bolero or Scorpio pickups, known for their high ground clearance and torquey engines. For instance, the common 2.5-liter m2DiCR diesel engine provides ample low-end torque, essential for moving a heavy load from a standstill, especially on unpaved roads. The focus here is on mechanical simplicity and serviceability, which translates to lower long-term maintenance costs.

Tank Construction and Specifications

The tank itself is the heart of the operation. Reputable builders use food-grade, corrosion-resistant materials like polyethylene (LLDPE) or coated mild steel.

- Capacity: Ranges typically from 2,000 to 6,000 liters, depending on the chassis model and axle configuration.

- Baffles: Internal baffles are non-negotiable. They prevent water from sloshing violently, which can destabilize the vehicle and stress the tank structure.

- Fittings: Look for robust brass or stainless-steel fittings for the fill cap, outlet valve, and drain plug. A functional manhole allows for interior inspection and cleaning.

John Miller, a fleet manager with over 15 years of experience in utility vehicle operations and a certified TESOL instructor who trains technical staff globally, emphasizes this point: “The difference between a good tanker and a great one is often in the details of the plumbing. Cheap plastic valves will fail under constant sun exposure and mechanical stress, leading to costly downtime. Always inspect the ancillary hardware as closely as the tank.”

Critical Buying Guide: What to Look For

Purchasing a water tanker is a significant investment. Beyond the brand name, you need to evaluate the complete package based on your specific operational needs.

Assessing Your Requirements

Start by asking the right questions:

- Primary Use: Is it for potable water delivery, firefighting reserve, or dust suppression? This dictates material and pump specifications.

- Terrain: Will it operate mostly on highways, farm tracks, or rugged construction sites? This influences the required axle configuration, tire type, and suspension.

- Water Source: How will you fill it? If drawing from ponds or shallow wells, a powerful suction pump is essential.

- Budget: Consider Total Cost of Ownership (TCO), including fuel efficiency, expected maintenance, and part availability.

Pump System and Delivery Options

The pump is what transforms a static water carrier into a functional tanker. You have two main choices:

- Engine-Driven PTO Pump: Powered directly by the truck’s engine via a Power Take-Off (PTO) unit. This offers high flow rates and pressure, ideal for firefighting or long-distance spraying.

- Diesel-Powered Independent Pump: A separate, small diesel engine powers the pump. It operates independently of the vehicle’s engine, allowing you to pump water while the truck is off, which can be more fuel-efficient for certain tasks.

A well-designed system will include a filter to protect the pump from debris and a pressure control valve.

Mahindra vs. Competitors: A Side-by-Side Look

How does a Mahindra-based tanker stack up against other common options? The table below provides a clear, at-a-glance comparison based on key operational parameters.

| Feature | Mahindra Pickup-Based Tanker | Large Commercial Truck Tanker (e.g., Tata) | Chinese Truck Factory Custom Tanker |

|---|---|---|---|

| Typical Capacity | 2,000 – 6,000 Liters | 8,000 – 20,000 Liters | 5,000 – 15,000 Liters |

| Maneuverability | Excellent for tight spaces, rural paths | Limited, requires good roads | Good, depending on chassis size |

| Initial Cost | Moderate | High | Competitive |

| Operating Cost (Fuel/Maint.) | Lower | Higher | Generally Lower |

| Best For | Farms, small municipalities, contractors | Large-scale municipal or industrial supply | Buyers seeking a balance of capacity, cost, and customization |

As you can see, the Mahindra pickup water tanker excels in applications where agility and lower operational costs are priorities over sheer volume. For those needing larger capacities but still mindful of budget, exploring options from a specialized Chinese Truck Factory can be worthwhile, as they often offer highly customizable solutions on robust chassis.

Maintenance and Safety: Ensuring Longevity

A water tanker is a working asset, and its lifespan depends heavily on proper care. Neglect can lead to premature failure, contamination, or even accidents.

Routine Maintenance Checklist

- Tank Hygiene: Regularly drain and clean the interior, especially if carrying potable water. Sediment and biofilm can build up quickly.

- Pump Care: Follow the pump manufacturer’s service schedule for oil changes and filter replacements. Never run it dry.

- Chassis Upkeep: Adhere to the standard Mahindra service intervals for engine oil, filters, and brake inspections. The added weight means brakes and suspension components wear faster.

- Pre-Winter Prep: In freezing climates, completely drain all water from the tank, pump, and pipes to prevent cracking.

Non-Negotiable Safety Features

Safety is paramount when moving several tons of liquid. Your tanker must have:

- Functional Brakes: Ensure the braking system is rated for the GVW (Gross Vehicle Weight).

- Clear Markings: Reflective tapes and “WATER” signs (non-hazardous material) are essential for road safety.

- Anti-Surge Protection: As mentioned, internal baffles are critical to control liquid movement.

- Secure Load: The tank must be firmly mounted to the chassis using high-grade U-bolts and anti-slip pads.

According to a 2022 NHTSA report, proper load securing is a major factor in preventing medium-duty truck incidents.

Frequently Asked Questions (FAQs)

Q: What is the typical fuel economy of a Mahindra water tanker?

A: It varies greatly based on load, terrain, and engine type. A 2,500-liter tanker on a Bolero chassis might average 10-12 km/liter when empty and 7-9 km/liter when full. Expect higher consumption with larger capacities and constant pump use.

Q: Can I use one tanker for both potable water and other uses like spraying?

A: It’s strongly discouraged. Cross-contamination risks are high. If you must, the tank requires a thorough, professional sanitization process between uses, as per WHO drinking-water guidelines. Dedicated tankers are always safer.

Q: How long does a properly maintained water tanker last?

A: The Mahindra chassis can last 10-15 years with good maintenance. The tank’s lifespan depends on material: a polyethylene tank can last 15+ years, while a steel tank may require refurbishment after 8-12 years, depending on corrosion protection and water chemistry.

Q: Is a new or used Mahindra water tanker a better value?

A: A new unit offers warranty, latest features, and known history. A used tanker can be a great value if you have it inspected by a qualified mechanic. Focus on rust (on chassis and tank mounts), pump service history, and any signs of repair or accident damage.

Making Your Final Decision

Choosing the right Mahindra pickup water tanker comes down to matching a reliable base vehicle with a high-quality tank and pump build. Prioritize builders with a proven track record, ask for customer references, and physically inspect the workmanship. Don’t just buy on price alone; consider durability, after-sales service, and part availability. By thoroughly understanding your needs and the features outlined in this guide, you’re well-equipped to invest in a water tanker that will be a dependable workhorse for your business or community needs.

Sources & Further Reading:

1. Vehicle Safety Considerations for Modified Trucks. National Highway Traffic Safety Administration (NHTSA). https://www.nhtsa.gov/road-safety/vehicle-safety.

2. Guidelines for Drinking-water Quality, 4th Edition. World Health Organization (WHO). https://www.who.int/publications-detail-redirect/9789241548151.

*Expert commentary provided by John Miller, Fleet Operations Manager (Name used with permission).

*Product specifications are based on common industry configurations and may vary by manufacturer.