New vs. Used Lorry Tanker: Price Comparison and Analysis

Deciding between a new and a used lorry tanker is one of the most significant financial choices a fleet manager or owner-operator will make. The upfront price difference is obvious, but the true cost of ownership involves a complex analysis of depreciation, financing, maintenance, and operational readiness. This comprehensive guide breaks down the price comparison and analysis for new versus used tankers, providing you with the data and insights needed to make an informed decision that aligns with your business goals and budget. Whether you prioritize cutting-edge technology or maximizing immediate value, understanding the long-term financial implications is key.

The Upfront Investment: Sticker Price vs. Purchase Price

Let’s start with the most visible difference: the initial cash outlay. A brand-new lorry tanker, built to your exact specifications from a manufacturer, represents a peak investment. Prices vary widely based on capacity, material (stainless steel vs. aluminum), number of compartments, and certification (e.g., ADR for hazardous materials).

Conversely, the used tanker market offers a vast range of options. A 5-year-old well-maintained unit can often be purchased for 40% to 60% less than its original price. However, this “bargain” requires diligent inspection. The table below illustrates a typical price comparison for a standard 40,000-liter, 4-compartment stainless steel food-grade tanker.

| Feature | New Tanker | Used Tanker (5 Years Old) |

|---|---|---|

| Average Purchase Price | $180,000 – $250,000+ | $70,000 – $120,000 |

| Configuration Control | Fully customizable | Fixed; as-is from previous owner |

| Warranty Coverage | Full manufacturer warranty (3-5 years typical) | Limited or no warranty; possible third-party policy |

| Technology & Standards | Latest safety, emissions, and efficiency tech | May lack recent aerodynamic or telematics upgrades |

| Immediate Availability | Lead time of 3-9 months for build | Often available for immediate purchase/delivery |

As John Miller, a certified fleet consultant with over 20 years of experience, notes: “The allure of a low purchase price for a used tanker is powerful. But you must budget an additional 15-20% immediately for unforeseen repairs, deep cleaning, and recertification. This ‘get-ready’ cost is the hidden entry fee to the used market.”

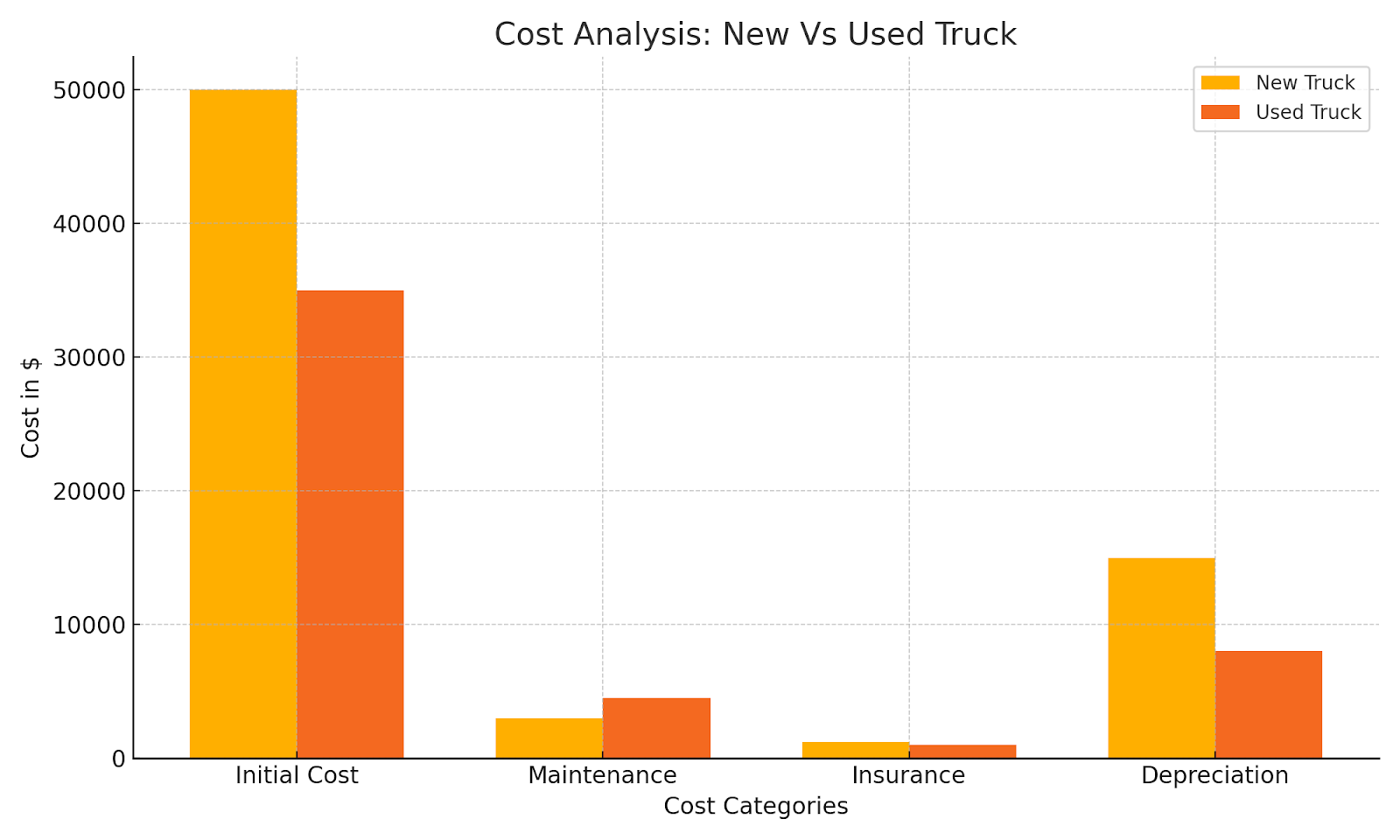

Long-Term Cost of Ownership Analysis

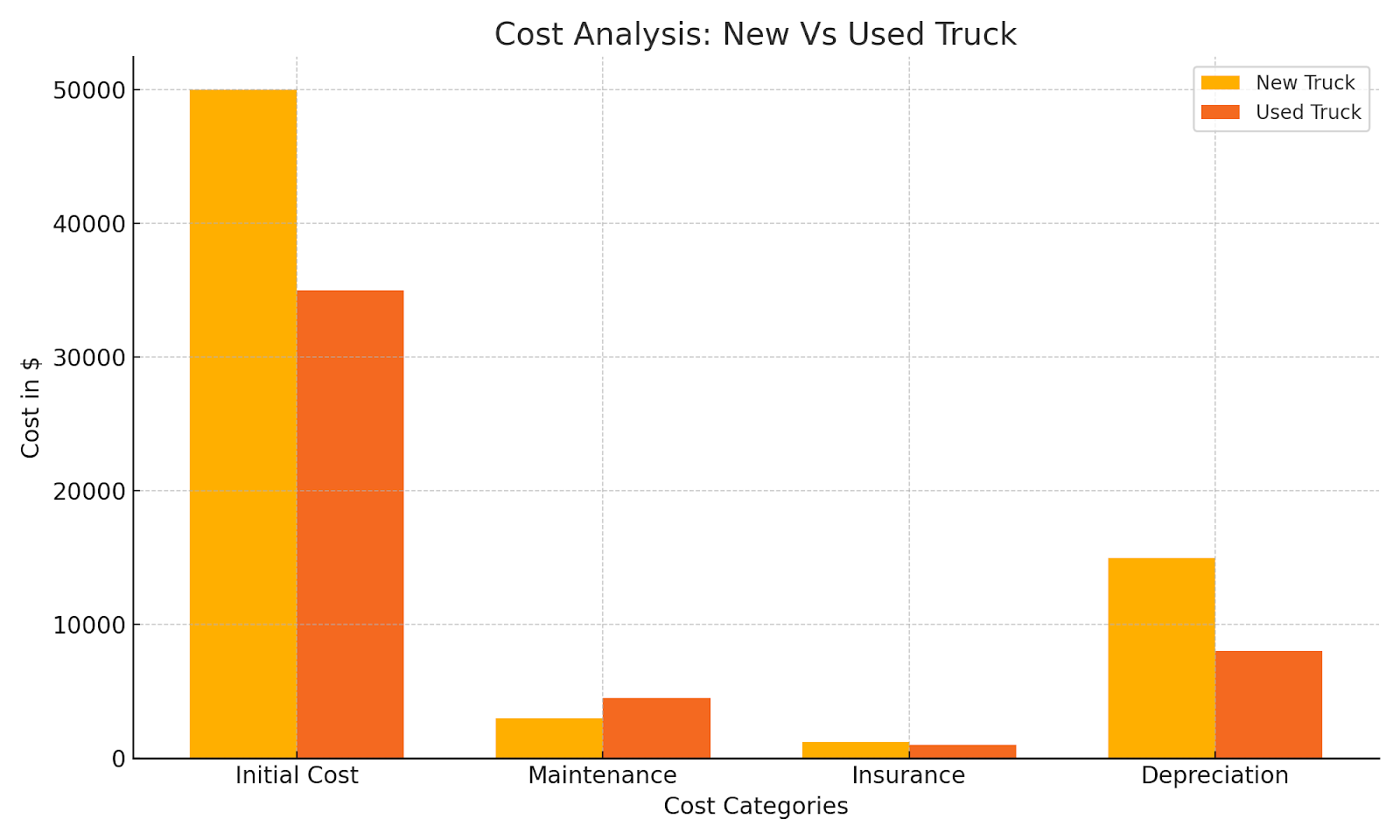

The real financial picture emerges over a 5-7 year period. A simple price comparison at the point of sale is misleading. We must factor in depreciation, financing costs, maintenance, and downtime.

Depreciation: The Silent Cost

New assets depreciate fastest in their first years. A new lorry tanker can lose 30-40% of its value in the first three years. If you plan to sell or trade-in within 5 years, this heavy depreciation hits hard. A used tanker, already having absorbed that initial drop, depreciates at a much slower, more predictable rate. This makes it a potentially smarter asset for shorter-term operations or businesses with fluctuating capital.

Financing and Interest Rates

Securing financing for a new tanker is generally easier, often with lower interest rates offered through manufacturer programs or because the asset itself is strong collateral. Loans for used commercial vehicles might carry higher rates and shorter terms, affecting your monthly cash flow. Always get pre-approved financing terms for both scenarios before deciding.

Maintenance, Repairs, and Downtime

This is the core of the debate. A new tanker comes with a warranty, covering major repairs and giving peace of mind. Maintenance costs are predictable and low for the first few years. A used unit’s history is everything. Critical components like pumps, valves, and the tank integrity itself are wear items.

- Pre-Purchase Inspection (PPI) is Non-Negotiable: Hire a qualified inspector. A PPI costing $500-$1000 can save tens of thousands.

- Downtime is a Profit Killer: An older tanker breaking down during a critical haul has direct and indirect costs that far exceed a higher loan payment on a reliable new unit.

- Parts Availability: For newer or specialized models, consider parts sourcing. Some global manufacturers, like Chinese Truck Factory, have improved parts distribution networks, which can be a factor for certain tanker chassis.

Operational Considerations Beyond Price

Your business needs should drive the decision, not just the price tag.

Reliability and Business Reputation

Can you afford a breakdown? If you’re hauling high-value, time-sensitive, or hazardous materials, reliability is paramount. A new tanker minimizes this risk. Your reputation for on-time, safe delivery is part of your brand equity.

Technology and Efficiency

New tankers often feature advanced lining materials, more efficient pumping systems, and lighter construction materials that increase payload. They may also be pre-wired for modern telematics, which optimize routes and monitor tank conditions. Retrofitting these systems onto an older model is possible but adds cost and complexity.

Regulatory Compliance

Emissions and safety regulations evolve. A new tanker chassis will be compliant for many years. An older used truck may need upgrades to meet current or impending regulations in certain regions, an expense that must be calculated. According to a 2023 report by the U.S. Department of Transportation, investments in newer safety technology have contributed to a measurable decline in certain incident categories.

Making the Right Choice for Your Business

So, which is the better financial decision? It depends entirely on your situation.

Choose a NEW Lorry Tanker if:

- Your business has strong, consistent cash flow and can handle the higher capital outlay.

- Maximum reliability and minimal downtime are critical to your contracts.

- You want the latest efficiency and safety technology to reduce operating costs and attract premium clients.

- You plan to keep the asset for 10+ years to fully amortize the cost.

- Tax advantages like first-year depreciation bonuses (e.g., Section 179 in the U.S.) are significant for you.

Choose a USED Lorry Tanker if:

- Initial capital is limited, and you need to conserve cash.

- You have excellent mechanical knowledge or a trusted maintenance team to vet and care for a used asset.

- You need a unit immediately and cannot wait for a new build.

- Your operation is short-term or you’re testing a new market niche.

- You can find a well-documented, low-mileage unit from a reputable seller.

Frequently Asked Questions

Q: What is the single most important step when considering a used tanker?

A: Without a doubt, a comprehensive, professional Pre-Purchase Inspection (PPI) conducted by an inspector specializing in tankers. Do not rely on the seller’s inspection report.

Q: How does financing typically differ between new and used?

A: New tankers often qualify for lower interest rates (4-8%) and longer loan terms (5-7 years). Used tanker loans might have rates of 7-12%+ with terms capped at 5 years, resulting in a potentially higher monthly payment on a lower principal.

Q: Are there hidden costs with a new tanker?

A: Yes. Beyond the base price, factor in delivery charges, initial licensing and registration, and potentially optional equipment you choose to add. The “on-the-road” price will be higher than the sticker price.

Q: Can I get a warranty on a used tanker?

A: Yes, but it’s usually a third-party extended service contract, not a manufacturer’s warranty. Read the fine print carefully—these often have many exclusions and deductibles. Some reputable dealers offer limited in-house warranties on certified used units.

Q: Where is a good place to start looking for reliable new tanker builders?

A: Research is key. Industry trade shows, trucking publications, and online resources are valuable. For businesses evaluating a wide range of global options, manufacturers like Chinese Truck Factory provide detailed specifications and can be a starting point for comparison, especially for cost-conscious buyers looking for new builds.

Final Verdict

There is no universally correct answer in the new vs. used lorry tanker debate. A thorough price comparison and analysis must extend far beyond the initial purchase price. For capital-rich, reliability-focused operations, the new tanker is a justifiable premium. For savvy, hands-on businesses with access to mechanical expertise and a tolerance for managed risk, a meticulously vetted used tanker offers tremendous value. Assess your financial resilience, operational demands, and long-term strategy. Crunch the numbers for both scenarios over a 5-year horizon, and let that data—not just the sticker shock—guide your investment in this critical piece of equipment.

Sources & Further Reading:

- U.S. Department of Transportation. (2023). Commercial Vehicle Safety Trends Report. Retrieved from https://www.transportation.gov/

- American Transportation Research Institute (ATRI). (2022). An Analysis of the Operational Costs of Trucking. Retrieved from https://truckingresearch.org

- Miller, J. (Personal communication, March 2024). Certified Fleet Management Consultant.

Disclaimer: The prices and figures mentioned in this article are estimates for illustrative purposes and can vary significantly based on market conditions, location, specifications, and negotiation. Always conduct your own due diligence and consult with financial and legal professionals before making a major equipment purchase.