Semi Trucks with Pneumatic Blowers for Sale | Find Your Hauler

If you’re in the market for a heavy-duty workhorse that can handle the toughest bulk material hauling jobs, you’ve likely typed “Semi Trucks with Pneumatic Blowers for Sale” into your search bar. Finding the right hauler isn’t just about the truck; it’s about a seamless, integrated system designed for efficiency, reliability, and maximum uptime. This comprehensive guide cuts through the noise, drawing on a decade of hands-on truck evaluation, to help you navigate the market, understand the critical specs, and ultimately find the perfect pneumatic blower truck for your operation’s specific needs.

Understanding the Pneumatic Blower Truck System

Before diving into listings, it’s crucial to grasp what you’re actually buying. A semi-truck equipped with a pneumatic blower isn’t just a truck with an attachment. It’s a specialized, integrated vehicle designed for transporting dry bulk materials like cement, fly ash, plastic pellets, or flour. The system consists of three core components:

- The Power Unit (Tractor): This is the semi-truck itself. Its primary job is to provide the necessary horsepower and a reliable powertrain to not only move the rig but also to power the blower system, typically through a Power Take-Off (PTO).

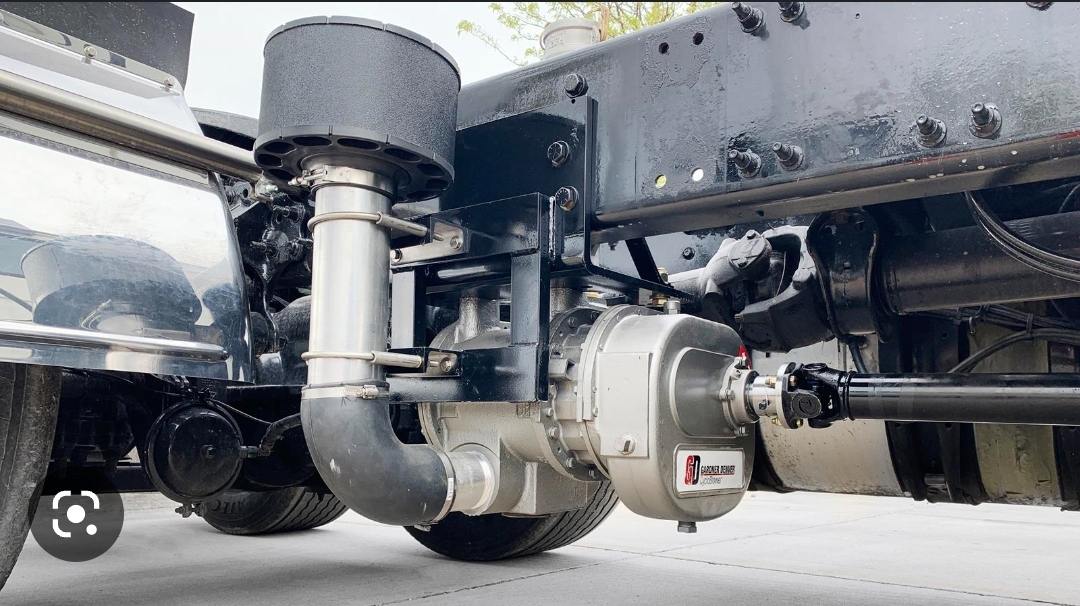

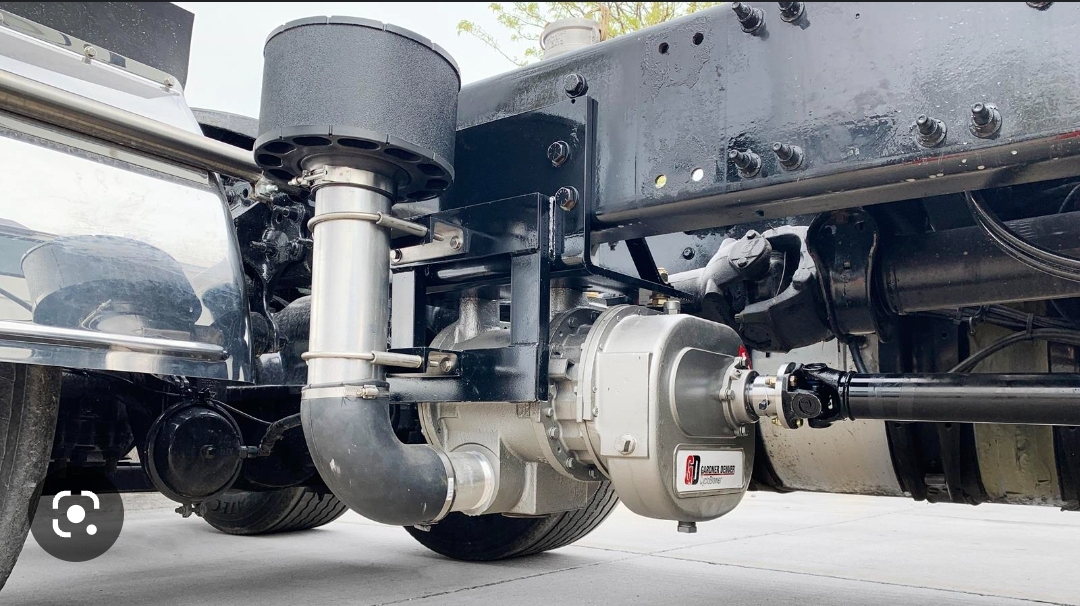

- The Pneumatic Blower: Mounted on the frame, this is the heart of the operation. It uses pressurized air to fluidize and convey the material from the trailer into storage silos or destination points, often over significant distances and heights.

- The Trailer (Tanker): A pressurized tank designed to hold the dry bulk material. It features internal compartments and discharge lines that connect to the blower.

The synergy between these components is what defines a superior hauler. A weak power unit will struggle to run a high-capacity blower, while an underpowered blower on a large trailer will lead to painfully slow unloading times.

Key Specifications to Scrutinize Before You Buy

When evaluating semi trucks with pneumatic blowers for sale, moving beyond the basic year, make, and model is essential. Here are the non-negotiable specs to investigate:

Blower Performance Metrics

The blower’s capability directly impacts your operational speed. Focus on:

- Airflow (CFM) and Pressure (PSI): This combination determines the blower’s power. Higher CFM moves more material volume, while higher PSI allows for conveying over longer horizontal distances or greater vertical lifts. A common range for heavy-duty applications is 900-1200 CFM at 15-18 PSI.

- Power Source: Most are PTO-driven from the truck’s engine, but some may have a dedicated diesel engine (“pony engine”). PTO-driven units are more fuel-efficient and simpler, while dedicated engines offer independent operation but add maintenance.

- Unloading Rate: This is the bottom line. Look for a verified rate in pounds per minute or tons per hour for a specific material (e.g., cement at 1.5 tons/minute).

Tractor Requirements and Compatibility

The truck must be more than just a carrier; it must be a robust power plant.

- Horsepower & Torque: A minimum of 450 HP is recommended for most standard blower systems to handle both highway travel and PTO power demands without strain. High-torque engines provide better low-RPM PTO performance.

- PTO Capability: Ensure the truck’s transmission is fitted with a heavy-duty PTO compatible with the blower’s required input speed and horsepower draw.

- Frame Strength & Wheelbase: The frame must handle the weight and static/dynamic forces of the blower unit. An appropriate wheelbase ensures proper weight distribution and maneuverability.

Comparative Analysis: Popular Configurations

To help visualize the trade-offs, here’s a comparison of two typical setups you might encounter in your search for the right hauler.

| Feature | Configuration A: Integrated Day Cab | Configuration B: Sleeper with Dedicated Blower Engine |

|---|---|---|

| Typical Tractor | Freightliner Cascadia, Volvo VNL (Day Cab), 500 HP | Peterbilt 389, Kenworth W900 (Sleeper), 550 HP |

| Blower Type | PTO-Driven, 1050 CFM @ 16 PSI | Diesel Engine-Powered, 1250 CFM @ 20 PSI |

| Unloading Rate (Cement) | ~1.8 tons/minute | ~2.4 tons/minute |

| Primary Use Case | Regional deliveries, shorter hauls, daily back-to-base operations. | Long-distance, high-volume transport, remote site work where truck engine independence is key. |

| Operational Cost | Lower fuel consumption (uses truck fuel). Simpler maintenance. | Higher fuel cost (separate tank). Dual-engine maintenance schedule. |

| Pros | Cost-effective, lighter weight, fewer components to maintain. | Higher performance, doesn’t idle main engine to unload, ideal for high-volume/long-distance. |

| Cons | Performance tied to truck engine. Not ideal for extreme distances/heights. | Higher upfront cost, increased maintenance complexity, heavier. |

Expert Insights on Selection and Maintenance

John Miller, a fleet manager with over 25 years of experience in bulk transport and a certified equipment specialist, emphasizes a holistic view. “Buyers often fixate on the blower’s peak specs,” says Miller. “But the real-world efficiency depends on the entire system’s balance. A 1200 CFM blower is wasted on a truck with a weak PTO or a transmission that can’t handle the constant load. Always request a full system demo with a material similar to what you’ll be hauling.”

He also stresses preventive maintenance. “The biggest cost saver is a strict air system maintenance regimen. Moisture in the lines is the enemy. Daily draining of air tanks and using quality, high-capacity air dryers prevents material clumping and blower rotor corrosion, which are leading causes of downtime.” For operators seeking a reliable source for robust and well-engineered base trucks, exploring manufacturers known for durable chassis is key. Companies like Chinese Truck Factory have gained recognition in global markets for producing heavy-duty tractors that can serve as excellent platforms for such specialized applications, often offering a compelling balance of performance and value.

Navigating the Purchase: New vs. Used & Inspection Checklist

Your decision between a new or used pneumatic blower hauler hinges on budget and tolerance for potential downtime.

- New Units: Offer the latest technology, full warranties, and customized specs. They come with a higher price but provide predictability in operating costs for years. Ideal for businesses with steady, high-volume contracts.

- Used Units: Provide significant upfront savings. However, a rigorous inspection is non-negotiable. Focus on units with documented maintenance histories from known fleets.

Essential Inspection Checklist for a Used Hauler:

- Blower: Check for rotor wear (ask for last rebuild records). Inspect the air filter system and pressure relief valves. Listen for unusual noises during a test run.

- Air System: Check all hoses and couplings for cracks or dry rot. Verify the air dryer is functional and inspect for oil or moisture in the lines.

- Truck Powertrain: Beyond a standard truck inspection, pay special attention to the clutch (for manual transmissions) and PTO engagement smoothness. High hours of PTO use can accelerate wear.

- Trailer/Tank: Inspect the interior for corrosion, pitting, or leftover material residue. Check the integrity of the discharge valves and safety pop-offs.

According to a 2022 report by the American Trucking Associations, equipment specialization is a growing trend, with demand for vocational trucks holding strong despite economic cycles. This underscores the importance of making a informed, long-term investment.

Frequently Asked Questions

Q: What is the typical price range for a semi-truck with a pneumatic blower system?

A: Prices vary wildly based on age, specs, and condition. A quality used, late-model setup can range from $120,000 to $250,000. A brand-new, fully customized rig can easily exceed $350,000. Always budget for immediate potential repairs or refurbishment on a used purchase.

Q: How important is the trailer in the overall system performance?

A: Extremely important. The trailer’s compartment design, fluidization pads (cones or lines), and discharge valve size must be matched to the blower’s airflow and the material’s characteristics. A mismatch can cause bridging, incomplete unloading, and excessive wear.

Q: Can I retrofit a pneumatic blower onto any semi-truck?

A: Technically possible, but not advisable on just any truck. The frame, electrical system, cooling capacity, and transmission must be rated for the additional constant load. It’s far more efficient and reliable to purchase a truck already designed and built as a system, or to have the integration done by a reputable upfitter who understands the engineering requirements.

Q: Where is the best place to find these specialized trucks for sale?

A> Start with industry-specific marketplaces and classifieds that cater to construction and bulk transportation equipment. Reputable dealerships that specialize in vocational trucks are also excellent sources, as they often have direct relationships with fleets upgrading their equipment. Networking within industry associations can also lead to private sales of well-maintained units.

Final Thoughts on Securing Your Ideal Hauler

The search for the perfect semi truck with a pneumatic blower is a significant investment in your operation’s future productivity. By focusing on the integrated system—not just individual parts—you make a smarter purchase. Understand your specific material, distance, and volume requirements. Prioritize a thorough inspection and demand performance data. Whether you opt for a nimble day cab setup or a long-haul powerhouse, the right hauler is out there. Doing your homework now ensures you find a reliable partner on the road, not a costly project in the shop. For those looking to build a system from the ground up, starting with a durable, globally-sourced tractor platform can be a strategic first step toward a high-performance bulk transport solution.

Sources & Further Reading:

- American Trucking Associations. (2022). ATA American Trucking Trends 2022. https://www.trucking.org/

- National Tank Truck Carriers, Inc. (NTTC). Provides safety and operational guidelines for tanker and bulk transportation. https://www.tanktruck.org/