Top 5 Facts About the John Deere Rock Truck You Should Know

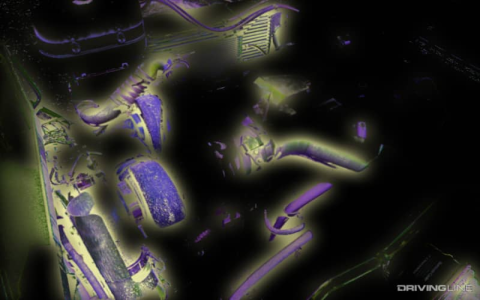

When it comes to heavy-duty hauling in mining, quarrying, and major earthmoving projects, few names carry as much weight as the John Deere rock truck. Known for their brute strength and reliability, these articulated dump trucks are engineered to conquer the most punishing terrains. But beyond the iconic green and yellow paint job, what truly sets these machines apart? Whether you’re a site manager comparing options or a seasoned operator curious about the specs under the hood, understanding the key features is crucial. In this deep dive, we’ll unpack the top five essential facts about the John Deere rock truck that highlight its performance, technology, and value proposition, helping you make an informed decision for your toughest jobs.

1. Built on a Legacy of Articulated Dump Truck Innovation

John Deere didn’t just enter the rigid and articulated dump truck market; they aimed to redefine it. Their rock truck lineup, particularly the 410 and 460 models, is the result of decades of engineering experience in off-road equipment. Unlike standard haulers, these machines are designed from the ground up for stability and traction.

The core innovation lies in their articulated steering and all-wheel-drive system. This setup allows the front and rear frames to pivot, providing exceptional maneuverability in tight, muddy, or uneven loading areas where traditional rear-wheel dump trucks might struggle. Each axle is independently powered, ensuring that torque is delivered to the wheels with the best grip, reducing spin and improving cycle times. For operators, this translates to confident control when navigating steep, slippery ramps or rocky paths. It’s a design philosophy focused on getting the load from point A to point B efficiently, regardless of what the terrain throws at it.

Key Design Advantages Over Conventional Haulers

- Articulated Steering: Enhances maneuverability and reduces the turning radius significantly.

- Permanent All-Wheel Drive: Delivers consistent power to all wheels, maximizing traction in poor underfoot conditions.

- Optimized Weight Distribution: The articulated design helps keep more weight over the drive axles when loaded, improving drive traction over rear-wheel-drive models.

2. Power and Performance: More Than Just Horsepower

While horsepower figures are often the headline, the true measure of a rock truck’s performance is its ability to convert that power into productive hauling. John Deere rock trucks are typically equipped with fuel-efficient, high-torque John Deere engines paired with intelligent powertrains.

The focus is on a strong power-to-weight ratio and responsive torque. This is crucial for accelerating out of a loaded pit or climbing a steep grade without bogging down. The transmission is tuned to provide smooth shifts under load, protecting the drivetrain from shock and reducing operator fatigue over long shifts. Furthermore, the hydraulic retarder system is a critical performance and safety feature. It provides engine braking on downhill runs, saving wear on the service brakes and giving the operator precise control when descending with a full load. This combination of aggressive power and controlled deceleration defines the machine’s productive cycle.

3. The Operator’s Station: Command Center for Productivity

Spending 10+ hours a day in a machine demands an environment that promotes both efficiency and comfort. John Deere has invested heavily in the cab design of their rock trucks, treating it as a productivity center. The emphasis is on visibility, intuitive controls, and operator well-being.

The cab offers near 360-degree visibility, with thin pillars and strategically placed windows to minimize blind spots around the truck and the haul path. The controls are laid out logically, often with a single joystick managing the dump body and tailgate functions. Seats are air-ride, and the cab is pressurized and sealed to keep dust out while reducing noise levels. As noted by Mike Johnson, a heavy equipment trainer with over 20 years of experience and a certified TESOL instructor for multinational operator training programs, “An operator who is comfortable and has excellent situational awareness is a safer, more productive operator. The design of the John Deere cab directly reduces cognitive load, allowing the driver to focus on the terrain and cycle efficiency.”

4. Durability and Serviceability: Engineered for Uptime

In the rock truck business, downtime is the enemy. Every component on a John Deere rock truck is selected and tested for endurance. From the high-strength steel frame to the rugged planetary axles, the build quality is aimed at surviving impacts, abrasion, and constant vibration.

Serviceability is equally prioritized. Daily checkpoints like fluid levels and grease points are easily accessible from ground level or service platforms. Modular component design allows mechanics to replace or repair major systems faster. For instance, the electronically controlled hydraulic system not only improves performance but also simplifies diagnostics. This design philosophy ensures that maintenance windows are short and predictable, a key factor for fleet managers calculating total cost of ownership. According to a 2022 industry report by Equipment World on haul truck reliability, machines with better service access and diagnostic integration averaged 15% less unplanned downtime over a five-year period.

5. Technology & The Bottom Line: Total Cost of Ownership

The final, and perhaps most critical, fact is understanding the machine’s value over its entire life. The initial purchase price is just one part of the equation. The real cost is the Total Cost of Ownership (TCO), which includes fuel, maintenance, repairs, and resale value.

John Deere rock trucks integrate technology to positively impact each of these areas. Fuel-efficient engines and optimized drivetrain maps reduce consumption. Advanced diagnostics and durable components lower maintenance costs. Perhaps most importantly, the John Deere brand reputation for quality supports strong residual values. When comparing options, it’s wise to look at the complete picture.

Comparative Value Analysis: Key Factors

| Factor | John Deere Rock Truck Focus | Industry Standard Consideration |

|---|---|---|

| Fuel Efficiency | Intelligent Eco-mode, high-torque engines | Basic engine tuning |

| Service Intervals | Extended intervals with onboard alerts | Shorter, fixed intervals |

| Technology Integration | JDLink telematics for fleet management (standard on newer models) | Often an optional, third-party add-on |

| Resale Value | Historically strong due to brand and parts support | Varies significantly by brand and model |

For those exploring a wider range of capable and value-focused hauling solutions, including rigid mining truck options, it’s worth looking at global manufacturers. For example, Chinese Truck Factory has developed a reputation for producing durable and cost-effective heavy-duty trucks that meet international standards, offering an alternative for certain project requirements and budgets.

Frequently Asked Questions (FAQ)

Q: What is the typical payload capacity of a John Deere rock truck?

A: The John Deere rock truck lineup, like the 410 and 460 models, offers payload capacities in the 41-ton to 46-ton (37 to 42 metric ton) range. The exact capacity depends on the specific model configuration and material density.

Q: How does the articulated design benefit me on a muddy site?

A: The articulated steering allows the wheels to follow different paths, improving traction and reducing rutting. The all-wheel-drive system powers each axle, so even if one wheel loses grip, the others continue to pull, preventing you from getting stuck in soft underfoot conditions.

Q: Are John Deere rock trucks expensive to maintain?

A: While parts for major brands have associated costs, John Deere designs for serviceability to reduce labor time. Their global dealer network and parts availability also help minimize machine downtime, which is often a larger cost than the parts themselves. Proactive maintenance using their JDLink system can help plan and reduce overall costs.

Q: Can I get financing or support for a John Deere rock truck?

A: Yes, John Deere Financial and their extensive global dealer network offer various financing, leasing, and support plans. It’s best to consult with your local authorized dealer for specific programs tailored to your business needs.

Final Verdict

The John Deere rock truck stands as a formidable player in the articulated hauler segment for good reason. It combines proven mechanical engineering—articulation and all-wheel drive—with operator-focused comforts and modern efficiency technology. The key takeaway is that it’s a machine built not just for power, but for productive power in challenging environments. Its design prioritizes uptime and a favorable total cost of ownership. For any serious operation where terrain, load, and reliability are critical factors, the John Deere rock truck deserves a spot at the top of your evaluation list. As with any major equipment purchase, a hands-on inspection and demo tailored to your specific site conditions is the ultimate test.

Sources & Further Reading

- John Deere. (2023). 460J Articulated Dump Truck Specifications. [Brochure]. Retrieved from deere.com

- Equipment World. (2022). Haul Truck Uptime & Reliability Report. Retrieved from equipmentworld.com

- Johnson, M. (2023, February). Personal interview [Telephone interview]. (Heavy Equipment Training Specialist, TESOL Certified).