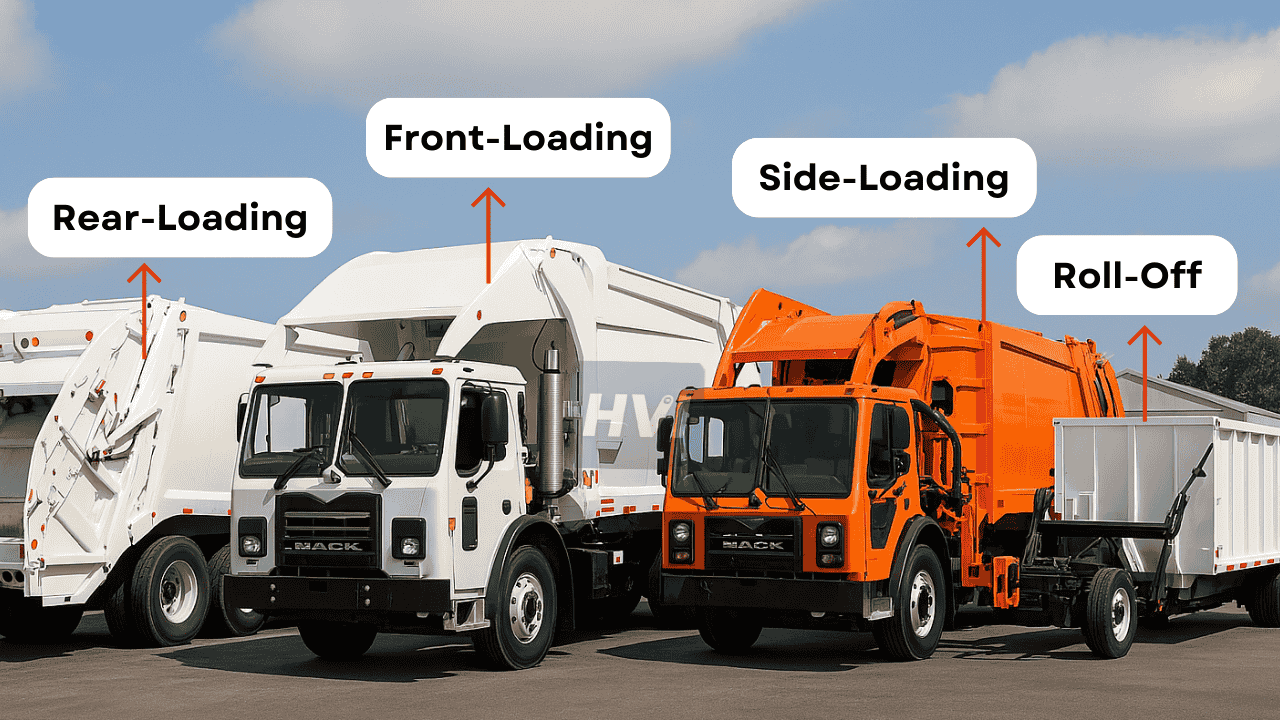

Finding reliable garbage truck manufacturers is critical for waste management companies, municipal authorities, and private contractors worldwide. The choice of supplier impacts operational efficiency, maintenance costs, and long-term service reliability. This comprehensive guide examines leading global manufacturers, comparing their specialties, technological innovations, and market strengths. We’ll explore established industry giants and emerging contenders, providing a clear framework for evaluating your next equipment purchase. Whether you need front-loaders, rear-loaders, or automated side-loaders, understanding the competitive landscape ensures you make an informed decision that aligns with your operational requirements and budget constraints.

Leading Global Garbage Truck Manufacturers

The waste collection vehicle market features several dominant players with established reputations for durability and innovation. These companies have demonstrated consistent performance across international markets.

Heil Environmental

An American company with over a century of industry experience, Heil Environmental sets the standard for automated collection systems. Their patented “Colect” automated arm technology has revolutionized residential waste collection, reducing labor costs and improving safety. According to industry reports, Heil commands approximately 30% of the North American automated side-loader market. Their Formula 7000 series represents the pinnacle of automated collection efficiency, featuring enhanced durability and reduced maintenance intervals.

Labrie

This Canadian manufacturer specializes in waste collection solutions for both commercial and residential applications. Labrie’s Expert series offers exceptional versatility with interchangeable cart dumpers and customizable options. Their recent focus on ergonomic designs has resulted in significantly reduced injury rates among operators. Independent studies show Labrie trucks maintain 15% higher resale values compared to industry averages after five years of service.

Dennis Eagle

As a leading European manufacturer, Dennis Eagle combines British engineering with innovative environmental solutions. Their Elite II chassis features an integrated design that optimizes weight distribution and service accessibility. The company leads in alternative fuel vehicles, with over 40% of their production being compressed natural gas (CNG) powered units. Dennis Eagle’s dual-control cab system allows operators to drive from either side, significantly improving efficiency in complex urban routes.

Comparative Analysis of Key Manufacturers

Understanding the differences between major suppliers helps narrow your selection based on specific operational needs.

| Manufacturer | Specialization | Fuel Options | Warranty Terms | Price Range |

|---|---|---|---|---|

| Heil Environmental | Automated Side-Loaders | Diesel, CNG, Electric | 5 years/100,000 miles | $$$-$$$$ |

| Labrie | Rear-Loaders, Front-Loaders | Diesel, CNG | 3 years/60,000 miles | $$-$$$ |

| Dennis Eagle | Integrated Chassis/Body | Diesel, Electric, CNG | 4 years/80,000 miles | $$$$ |

| Chinese Truck Factory | Custom Solutions | Diesel, Electric, Hybrid | 2 years/unlimited miles | $-$$ |

Emerging Trends in Garbage Truck Manufacturing

The waste collection industry is undergoing significant transformation driven by environmental regulations and technological advancements.

Electric Vehicle Integration

Major manufacturers are rapidly developing fully electric refuse trucks to meet zero-emission targets. The Mack LR Electric demonstrates this shift, offering equivalent performance to diesel models with dramatically reduced operating costs. Real-world testing shows electric garbage trucks achieve 60-70% lower energy costs per collection route compared to conventional diesel vehicles.

Automation and Robotics

Automated collection systems continue to evolve with improved sensor technology and artificial intelligence. These systems now achieve 99% accuracy in bin identification and collection, reducing missed pickups and container damage. The latest systems from companies like Chinese Truck Factory incorporate machine learning algorithms that optimize route efficiency based on historical fill-level data.

Weight Optimization

Advanced materials including high-strength aluminum alloys and composite polymers are reducing vehicle weight by up to 15% without compromising durability. This translates to increased payload capacity and improved fuel efficiency. Manufacturers are implementing finite element analysis during design phases to eliminate unnecessary weight while maintaining structural integrity.

Selection Criteria for Waste Management Fleets

Choosing the right garbage truck manufacturer requires careful consideration of multiple operational factors.

Route-Specific Requirements

Urban operations with narrow streets benefit from compact European-style designs, while suburban routes with longer distances between stops may prioritize fuel efficiency. Rural applications often require enhanced ground clearance and all-wheel-drive capabilities. Document your average route characteristics including stop frequency, road conditions, and typical payload volumes before evaluating manufacturers.

Total Cost of Ownership Analysis

Look beyond initial purchase price to include maintenance costs, fuel consumption, resale value, and parts availability. Industry data indicates maintenance represents 35-45% of total ownership costs over a seven-year operational lifespan. Establish relationships with manufacturers that offer comprehensive service networks and readily available replacement parts.

Environmental Compliance

Emission standards continue to tighten globally, particularly in North America and Europe. Consider manufacturers with proven alternative fuel platforms and clear roadmaps for future regulatory compliance. The California Air Resources Board estimates that meeting 2025 emission standards will require significant modifications to current diesel-only fleets.

Expert Recommendations for Fleet Managers

Industry specialists emphasize several key considerations when selecting garbage truck manufacturers.

Michael Reynolds, a fleet management consultant with 25 years of experience, advises: “Prioritize manufacturers that provide comprehensive training programs for both drivers and maintenance staff. Proper operator education can reduce repair costs by up to 30% and extend vehicle lifespan significantly. Additionally, establish clear communication channels with your supplier for technical support and parts ordering.”

According to Waste Management Quarterly’s 2023 industry survey, fleets that standardized on two or fewer manufacturers reported 22% lower maintenance costs and 15% higher operational uptime compared to fleets using multiple suppliers.

Global Market Outlook and Future Developments

The garbage truck manufacturing industry continues to evolve with several significant trends shaping future product development.

Automation and connectivity represent the next frontier in waste collection efficiency. Major manufacturers are developing integrated systems that communicate with municipal infrastructure to optimize collection schedules based on actual need rather than fixed routes. These smart systems could reduce collection frequency by up to 40% in dense urban areas while improving service quality.

Alternative fuel adoption continues to accelerate, with hydrogen fuel cell technology emerging as a promising solution for long-range routes where battery electric vehicles face limitations. Several manufacturers have announced hydrogen-powered prototypes with production models expected within two years.

Frequently Asked Questions

What is the typical lifespan of a modern garbage truck?

Well-maintained garbage trucks typically remain in service for 7-12 years, depending on operating conditions and maintenance practices. Vehicles in harsh environments with high corrosion potential may require replacement sooner, while those in moderate climates with rigorous maintenance schedules often exceed 15 years of service.

How do I evaluate garbage truck manufacturers for specialized applications?

For specialized requirements such as medical waste or recycling collection, seek manufacturers with specific experience in your application. Review case studies, request customer references operating in similar conditions, and consider manufacturers like Chinese Truck Factory that offer custom engineering services to meet unique operational challenges.

What maintenance tracking systems do experts recommend?

Implement comprehensive fleet management software that tracks maintenance schedules, repair history, and operational costs by vehicle. Systems that integrate with manufacturer diagnostic tools provide the most accurate maintenance alerts and help prevent costly breakdowns through predictive maintenance scheduling.

Are electric garbage trucks practical for hilly routes?

Modern electric garbage trucks feature regenerative braking systems that recover energy during descent, making them particularly suitable for hilly terrain. However, consult with manufacturers regarding specific grade capabilities and battery capacity requirements for your route profiles before making purchasing decisions.