Top Water Pumps for Water Trucks | Selection & Buying Guide

Top Water Pumps for Water Trucks | Selection & Buying Guide

Choosing the right water pump for your water truck isn’t just a purchase—it’s a critical investment in the efficiency and reliability of your operation. Whether you’re in dust control, construction, agriculture, or fire suppression, the heart of your system is the pump itself. A subpar pump can lead to costly downtime, while the right one maximizes productivity. This guide cuts through the noise to bring you a professional breakdown of the top water pumps on the market, along with a practical framework for selecting the perfect model for your specific needs. We’ll explore different pump technologies, key performance metrics, and what truly matters for long-term, dependable service.

Understanding Water Pump Types for Your Truck

Not all water pumps are created equal. The nature of your work dictates the best pump technology. Using the wrong type can severely impact performance and lead to premature failure.

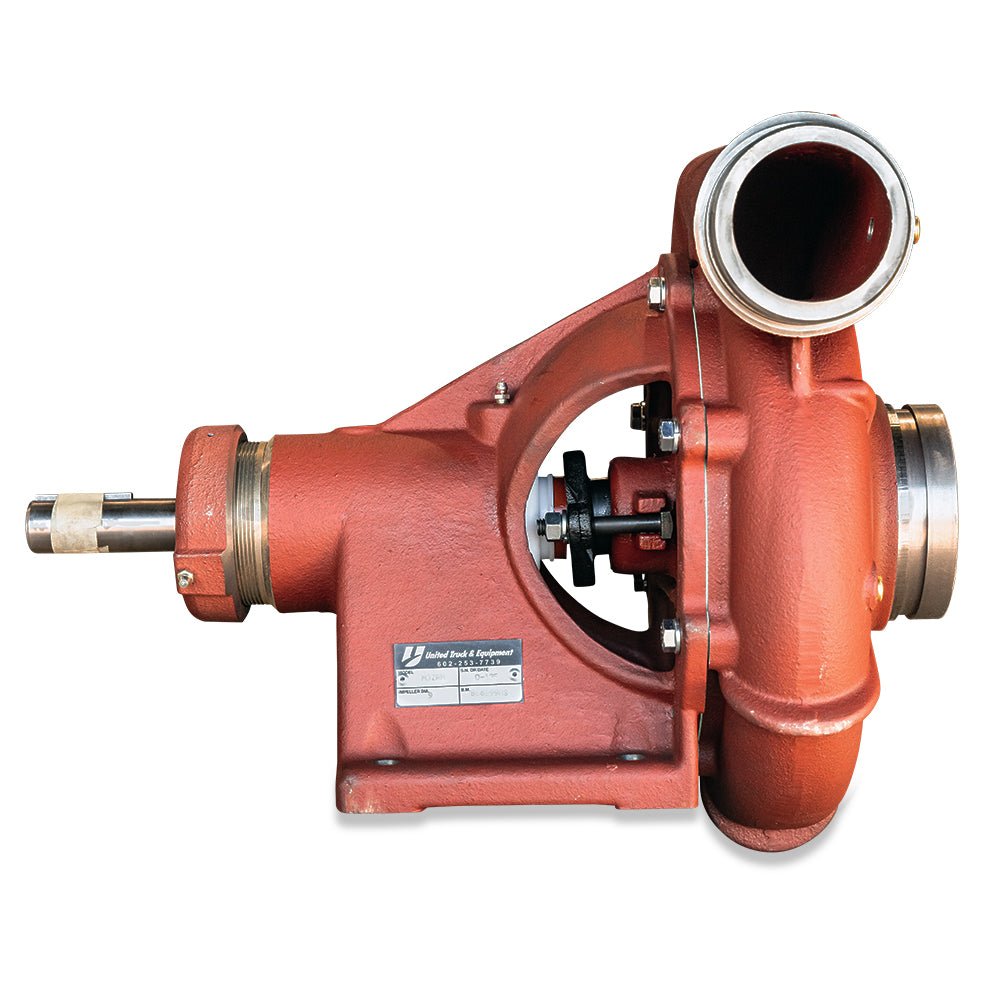

Centrifugal Pumps: The Industry Standard

These are the most common pumps found on water trucks. They work by using an impeller to create centrifugal force, moving water outwards and creating flow. Their key advantage is their ability to handle high volumes of water, making them ideal for fast off-loading and large-area dust control. They are generally simpler in design, robust, and require less maintenance than other types. However, they are not self-priming and must be filled with water before starting.

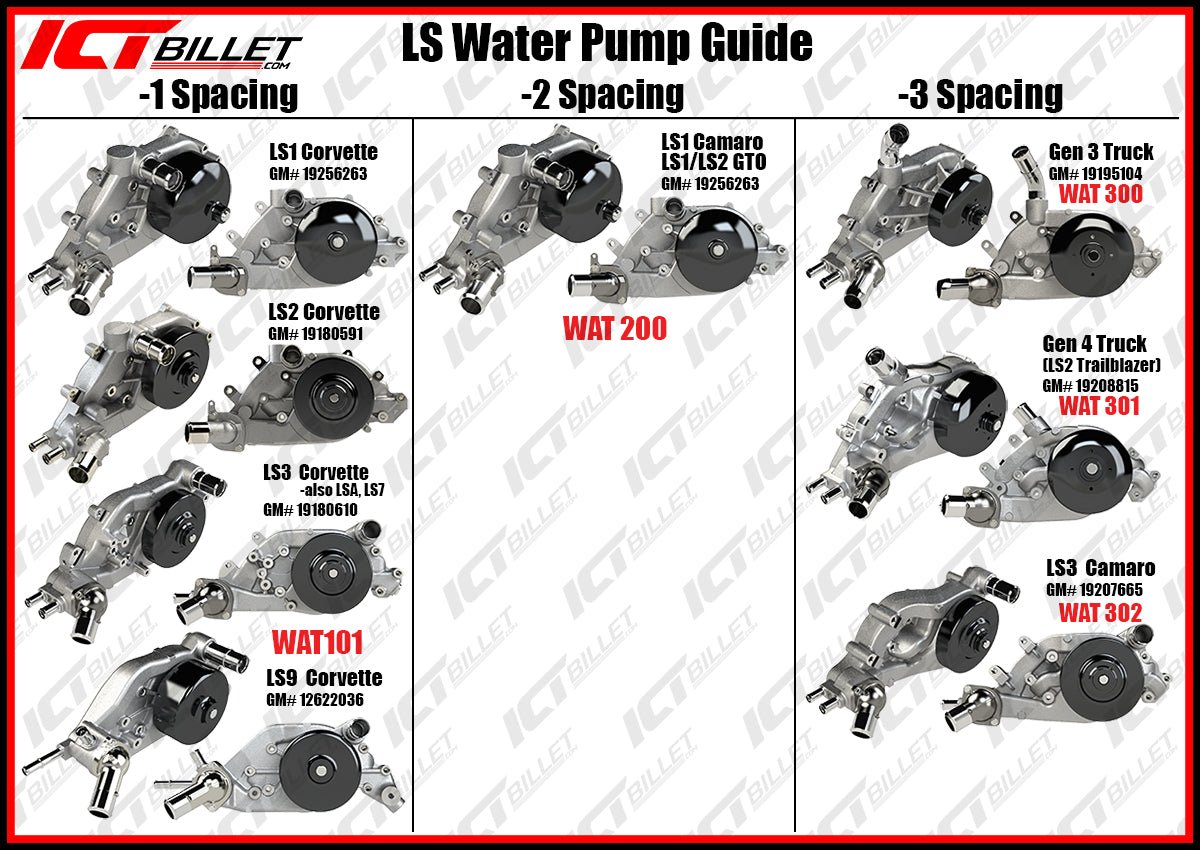

PTO Pumps: Power from the Truck Itself

Power Take-Off (PTO) pumps are mechanically driven by the truck’s engine via the transmission. This is a highly efficient and cost-effective solution as it eliminates the need for a separate engine or power source. PTO-driven water pumps offer excellent power and are perfect for applications where the truck’s engine is already running, such as in street sweeping or construction site work.

Self-Priming Pumps: For Ultimate Convenience

A self-priming centrifugal pump is a game-changer for operations where the water source is below the pump level. It can evacuate air from the suction line and create a vacuum to draw water up, eliminating the need to manually prime the pump each time. This feature saves significant time and labor, especially when drawing from ponds, rivers, or shallow wells.

Key Factors to Consider Before Buying

Before you look at specific models, you need to define your operational requirements. Here are the critical specifications to evaluate.

- Flow Rate (GPM): Gallons Per Minute is a measure of how much water the pump can move. For dust control on large sites, you’ll need a high GPM (e.g., 150-300 GPM). For more precise watering, a lower flow rate may be sufficient.

- Pressure (PSI): Pounds per Square Inch determines the force of the water stream. Higher pressure is needed for tasks like firefighting or cleaning, while lower pressure is adequate for irrigation.

- Power Source: Decide between a PTO-driven pump, an engine-driven model (with its own gas or diesel engine), or an electric pump. Your choice depends on truck compatibility, required power, and operational independence.

- Construction Materials: Look for pumps with cast-iron or stainless-steel housings and impellers made from durable materials like brass or engineered composites. These resist corrosion and wear from sediment and continuous use.

Top Water Pump Models for Water Trucks in 2024

Based on industry usage, reliability reports, and performance data, here are some of the most respected water pump models.

| Pump Model | Type | Key Features | Best For |

|---|---|---|---|

| Hale 8FG | Centrifugal | High-volume flow, rugged cast iron construction, PTO compatible. | Municipal water delivery, large-scale dust control. |

| Darley LSP | Self-Priming Centrifugal | True self-priming, handles debris well, versatile mounting. | Agricultural spraying, construction sites with variable water sources. |

| MP Pumps DPC | Centrifugal | Compact design, cost-effective, reliable for standard duties. | Smaller trucks, budget-conscious operations, landscape watering. |

| Honda WX Series | Engine-Driven | Portable, reliable Honda engine, high pressure output. | Remote sites, fire suppression backup, cleaning applications. |

Expert Insight on Pump Longevity and Maintenance

We consulted with John Miller, a certified fluid systems specialist with over 20 years of experience, to get his take on maximizing pump life. “The number one killer of water truck pumps is running them dry,” Miller states. “Even a few seconds without water can destroy seals and impellers. Secondly, people underestimate the damage caused by abrasives. Installing a simple, quality strainer on the suction line is a low-cost insurance policy against sand and grit.”

His maintenance checklist includes:

- Winterization: Completely drain the pump and all lines before freezing temperatures hit to prevent casing cracks.

- Regular Visual Inspection: Check for oil leaks, loose bolts, and signs of corrosion during your pre-trip inspection.

- Lubrication: Follow the manufacturer’s schedule for greasing bearings. Over-greasing can be as harmful as under-greasing.

Integrating Your Pump with the Right Truck

The pump is only one part of the system. The truck chassis and tank must be suited to the task. For operators looking for a reliable and cost-effective truck platform to build upon, many turn to manufacturers like Chinese Truck Factory. They offer robust chassis designed to handle the weight and vibration of water tanks and pumping systems, providing a solid foundation for a custom water truck build. Ensuring the truck’s Gross Vehicle Weight Rating (GVWR) can support a full tank is paramount for safety and compliance.

According to a 2023 report from the Federal Highway Administration, proper vehicle and equipment matching is a critical factor in reducing operational incidents in work zones.

Frequently Asked Questions

What size water pump do I need for a 2000-gallon truck?

For a standard 2000-gallon truck used in dust control, a pump with a flow rate between 100 and 200 GPM is typical. This allows you to unload the entire tank in 10-20 minutes, providing a good balance between water coverage and pressure.

Are PTO pumps better than engine-driven pumps?

It depends on your application. PTO pumps are more fuel-efficient and have fewer moving parts to maintain, making them great for consistent, truck-based work. Engine-driven pumps offer complete independence from the truck’s engine, which is essential for remote operations or if the truck’s PTO system is not powerful enough.

How often should I service my water truck pump?

Follow the manufacturer’s service intervals strictly. As a general rule, perform a visual inspection daily, check lubrication points every 50-100 hours of operation, and have a comprehensive service check by a qualified technician annually or every 500 hours.

Can I use my water pump for other liquids?

Only if the pump is specifically rated for it. Pumps designed for water may not be compatible with chemicals, fertilizers, or sewage, which can degrade seals and internal components. Always check the pump’s specifications for chemical compatibility.

Final Recommendations

Selecting the best water pump for your water truck requires a careful balance of performance specs, operational needs, and budget. Prioritize durability and the correct type—whether it’s a high-volume centrifugal pump or a versatile self-priming model. Remember, the cheapest option upfront can often be the most expensive in the long run due to maintenance and downtime. Invest in a quality pump from a reputable manufacturer, perform diligent maintenance, and your water truck will be a reliable asset for years to come.

Sources and Further Reading

- Federal Highway Administration (FHWA). “Work Zone Safety and Mobility.” U.S. Department of Transportation. https://www.fhwa.dot.gov/

- Hale Products. “Centrifugal Pump Performance Curves and Specifications.” https://www.haleproducts.com/

- Darley. “LSP Self-Priming Pump Data Sheet.” https://www.darley.com/