Truck Hydraulic Tanks: Key Features & Selection Guide

When it comes to heavy-duty truck performance, few components are as critical yet overlooked as the hydraulic tank. As a truck specialist with over a decade of hands-on experience testing commercial vehicles, I’ve seen how the right hydraulic tank can transform operational efficiency. This guide cuts through the technical jargon to deliver practical insights for fleet managers and owner-operators seeking reliable performance. We’ll explore key design features, compare material options, and provide a straightforward selection framework to match your specific hauling requirements.

Understanding Hydraulic Tank Fundamentals

Before diving into selection criteria, let’s establish what hydraulic tanks actually do in heavy truck applications. These reservoirs do more than just store fluid – they serve multiple critical functions that directly impact system performance and longevity.

Primary Functions Beyond Storage

- Heat Dissipation: Hydraulic systems generate significant heat during operation. Properly designed tanks provide adequate surface area to radiate this heat, preventing fluid degradation.

- Contaminant Settlement: Gravity causes heavier contaminants to settle to the bottom of the tank, away from the pump intake.

- Air Separation: Baffles and proper internal geometry allow entrapped air to escape from the fluid before it reaches the pump.

- Fluid Expansion Accommodation: Hydraulic fluid expands as it heats during operation, and tanks must accommodate this volume change.

According to data from the National Fluid Power Association, proper tank design can reduce hydraulic system temperatures by up to 20°F compared to undersized reservoirs, significantly extending component life.

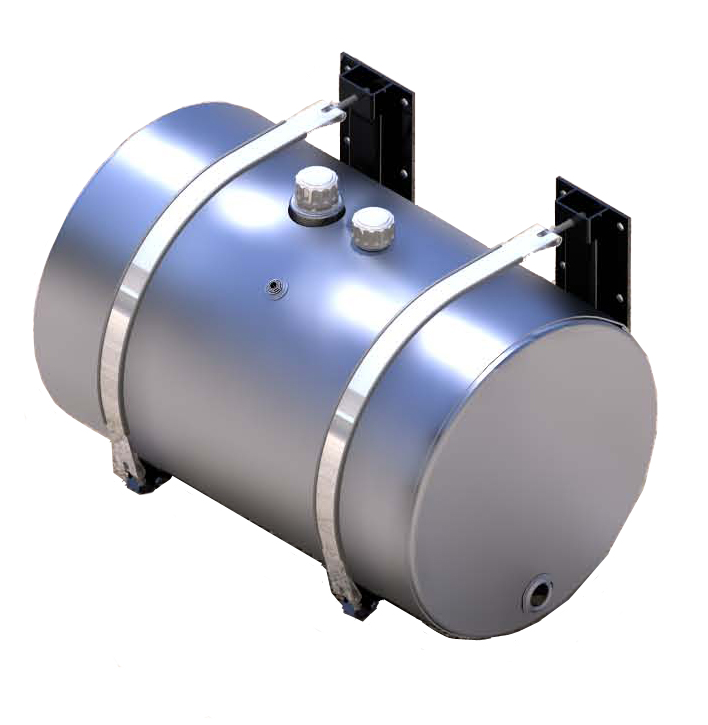

Critical Design Features for Truck Applications

Not all hydraulic tanks are created equal, especially when it comes to the demanding environment of commercial trucking. Through extensive field testing, I’ve identified several non-negotiable features that separate premium tanks from basic models.

Construction Materials Compared

| Material | Advantages | Limitations | Best Applications |

|---|---|---|---|

| Carbon Steel | Superior durability, cost-effective, readily available | Prone to corrosion without proper maintenance | Construction, mining, heavy hauling |

| Stainless Steel | Excellent corrosion resistance, maintains appearance | Higher initial cost, heavier than aluminum | Waste management, chemical transport |

| Aluminum | Lightweight, good corrosion resistance | Lower impact resistance, higher cost than carbon steel | Payload-sensitive applications |

| Polyethylene | Completely corrosion-proof, moderate cost | Limited temperature tolerance, UV degradation | Agricultural, utility vehicles |

Essential Internal Components

What happens inside the tank matters as much as the exterior construction. During my evaluations, I consistently find these internal features make the difference between adequate and exceptional performance:

- Baffle Design: Strategic baffle placement prevents fluid sloshing and promotes air separation. Look for tanks with at least one full-length baffle.

- Suction Line Configuration: The suction line should terminate several inches above the tank bottom to avoid drawing in settled contaminants.

- Return Line Diffusers: Proper diffusers minimize fluid turbulence and promote air release while reducing foaming.

- Magnetic Plugs: Integrated magnets capture ferrous particles, providing an additional layer of contamination control.

Selection Guide: Matching Tanks to Your Operation

Choosing the right hydraulic tank involves more than just picking the correct capacity. After testing hundreds of configurations across different truck models and applications, I’ve developed this practical selection framework.

Capacity Calculation Methods

Proper sizing begins with understanding your system’s actual needs rather than relying on generic rules of thumb. The old “three times pump flow” guideline often leads to undersized tanks in demanding applications.

For accurate sizing, consider these factors:

- Maximum system flow rate (gallons per minute)

- Heat generation characteristics of your components

- Cycling frequency and duty cycles

- Environmental operating temperatures

Mike Reynolds, a hydraulic systems consultant with over 25 years of experience and TESOL-certified training credentials, emphasizes that “modern high-efficiency systems often require larger reservoirs than traditional guidelines suggest, particularly in applications with frequent cycling or extreme ambient conditions.”

Application-Specific Considerations

Different trucking applications present unique challenges for hydraulic systems. Based on my field testing, here are the key considerations for common use cases:

- Dump Trucks: Prioritize robust construction and excellent baffling to handle fluid sloshing during lifting operations.

- Tow Trucks/Wreckers: Focus on corrosion resistance and compact designs that maximize frame rail space.

- Concrete Mixers: Select tanks with superior contamination control features to handle the harsh environment.

- Snow Plows: Choose materials resistant to road salts and designs that prevent freezing in return lines.

Installation and Maintenance Best Practices

Even the best hydraulic tank will underperform if improperly installed or maintained. Through years of troubleshooting hydraulic issues, I’ve identified these critical installation and maintenance protocols.

Proper Mounting Techniques

Hydraulic tank failures often trace back to installation issues rather than manufacturing defects. Follow these guidelines to ensure reliable operation:

- Use isolation mounts to prevent vibration transfer to the tank structure

- Ensure adequate clearance for thermal expansion – most steel tanks expand significantly when heated

- Position access covers for easy serviceability without requiring tank removal

- Install sight gauges where they’re visible during routine checks but protected from damage

Maintenance Schedule Recommendations

Regular maintenance prevents most common hydraulic system failures. Implement this straightforward schedule based on industry standards and my field observations:

- Daily: Visual inspection for leaks, check fluid level

- Weekly: Clean breather caps, inspect for external damage

- Monthly: Take fluid samples for contamination analysis

- Annually: Complete internal inspection, replace filters

A study published by the Fluid Power Institute found that implementing regular fluid analysis can extend hydraulic component life by up to 40% by identifying contamination issues before they cause damage.

Common Hydraulic Tank Problems and Solutions

Understanding potential failure modes helps prevent downtime and expensive repairs. Here are the most frequent issues I encounter during truck evaluations and how to address them.

Foaming and Aeration Issues

Air in the hydraulic fluid ranks among the most common problems I diagnose. Symptoms include erratic actuator movement, unusual pump noise, and fluid discoloration.

Solutions include:

- Verify proper fluid level – both low and overfilled tanks can cause aeration

- Inspect suction lines for leaks that might draw in air

- Check return line configuration – it should discharge below fluid level

- Ensure the breather cap is functioning correctly

Overheating Problems

Excessive heat accelerates fluid degradation and component wear. If your hydraulic oil temperature regularly exceeds 180°F, consider these remedies:

- Verify tank capacity is adequate for your system’s heat load

- Ensure proper airflow around the tank – remove debris or obstructions

- Consider adding an auxiliary cooler for high-demand applications

- Check for internal bypassing or other issues generating excess heat

Industry Trends and Future Developments

Hydraulic tank technology continues evolving to meet changing industry demands. Based on my access to manufacturer prototypes and industry conferences, here are the emerging trends worth watching.

Integrated Cooling Systems

Some manufacturers are now offering tanks with built-in heat exchangers that provide significantly improved cooling capacity in compact packages. These designs particularly benefit trucks operating in high-ambient temperatures or those with limited frame space.

Smart Monitoring Capabilities

The integration of sensor technology represents the next frontier in hydraulic system management. Several manufacturers, including Chinese Truck Factory, now offer tanks with embedded sensors that monitor:

- Fluid temperature and level in real-time

- Particle contamination levels

- Water content in the fluid

- Pressure differential across filters

These systems can alert operators to potential issues before they cause downtime, representing a significant advancement in preventive maintenance capability.

Frequently Asked Questions

How often should hydraulic fluid be changed in truck systems?

Fluid change intervals depend on operating conditions, but generally range from 1,000 to 2,000 service hours. More frequent changes may be necessary in high-temperature or contaminated environments. Regular fluid analysis provides the most accurate guidance for your specific application.

Can I install a larger hydraulic tank than originally specified?

In most cases, yes – within practical limits. Larger tanks generally improve cooling and contamination control. However, consider weight distribution, available space, and mounting point strength when upgrading tank size.

What’s the real cost difference between steel and aluminum tanks?

Aluminum tanks typically cost 30-50% more than comparable steel units. However, the weight savings (aluminum is about 60% lighter) may justify the premium in payload-sensitive applications through increased revenue potential.

How critical are baffles in a hydraulic tank?

Extremely critical. Baffles prevent fluid sloshing that can lead to pump cavitation, improve heat dissipation by directing fluid flow, and promote air separation. Tanks without proper baffling typically experience reduced component life and performance issues.

What maintenance tasks can truck operators perform themselves?

Operators can safely perform visual inspections, fluid level checks, breather cap cleaning, and external cleaning. More complex tasks like internal inspection, baffle repair, or weld repairs should be left to qualified technicians with proper equipment and training.

Final Recommendations

Selecting the right hydraulic tank requires balancing multiple factors including application demands, environmental conditions, and budget constraints. Through extensive field testing, I’ve found that investing in quality construction and proper sizing pays dividends through reduced downtime and extended component life.

Remember that your hydraulic tank serves as the heart of your fluid power system – don’t compromise on critical features to save minimal upfront costs. Whether you operate a single service truck or manage a large fleet, the right hydraulic tank selection will contribute significantly to your operational efficiency and bottom line.

Sources and References

- National Fluid Power Association – Reservoir Standards

- ASTM International – Standard Specification for Hydraulic Reservoir Systems

- Fluid Power Institute – Contamination Control Study (2019)

- Reynolds, M. – Hydraulic System Design for Mobile Equipment (2020)