Two in One Tar Tankers for Sale | Dual-Purpose Transport Solutions

In the demanding world of commercial transport and logistics, efficiency isn’t just a goal—it’s the bottom line. Operators constantly seek versatile, cost-effective assets that can adapt to shifting market demands without compromising on reliability or safety. This is where the innovative concept of two in one tar tankers truly shines, offering a brilliant dual-purpose transport solution. These specialized semi-trailers are engineered to carry two distinct, often sequential, payloads—typically hot asphalt (bitumen) and then diesel fuel or heating oil—on a single trip. For fleet managers looking to maximize asset utilization and boost profitability, understanding the value proposition of a two in one tar tanker for sale is crucial. This deep dive explores the mechanics, benefits, and key considerations, providing the insights you need from a decade of hands-on truck and trailer evaluation.

What Exactly is a Two-in-One Tar Tanker?

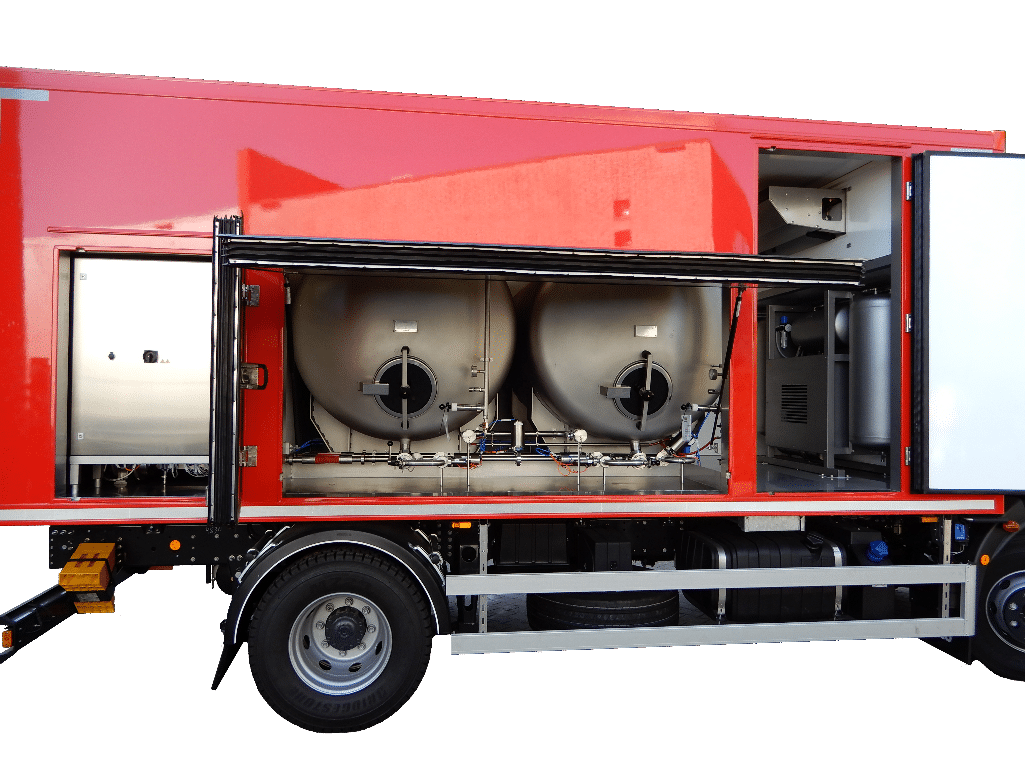

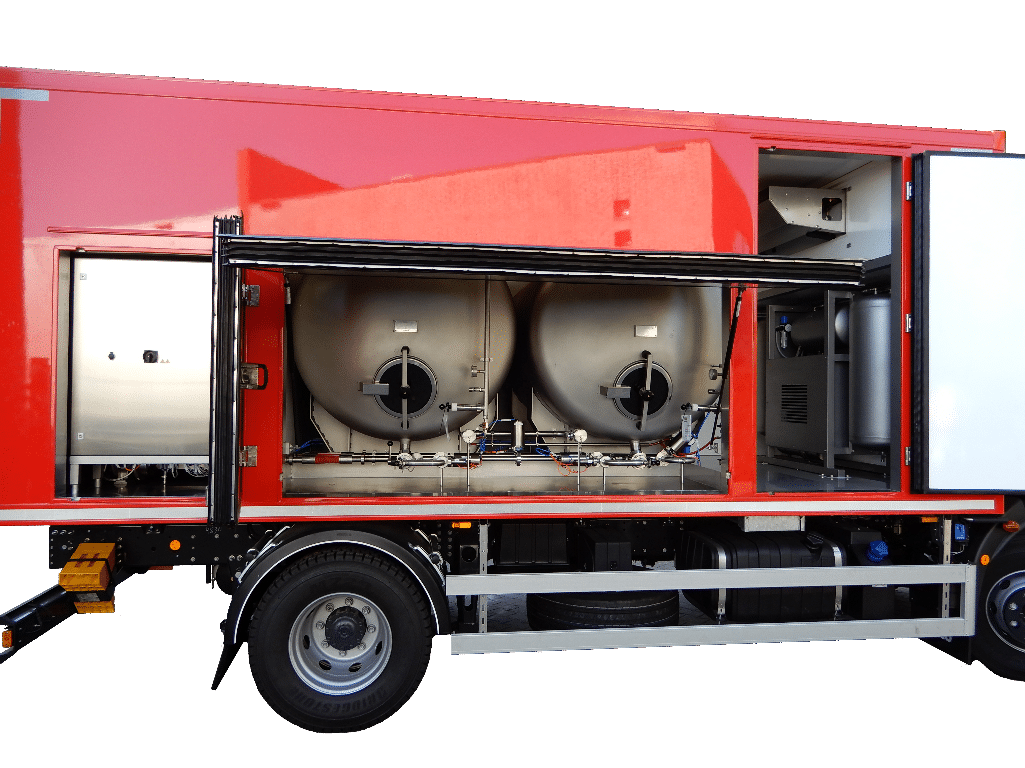

At its core, a two-in-one tar tanker, often called a combo tanker or dual-compartment bitumen/fuel tanker, is a masterpiece of practical engineering. Unlike standard tankers dedicated to a single product, this design incorporates two completely separate and insulated compartments within a single chassis frame. The front compartment is typically a heated, insulated tank designed for transporting hot liquid asphalt or bitumen, equipped with heating coils and thick insulation to maintain temperature. The rear compartment is a standard tank for transporting diesel fuel, gas oil, or similar petroleum products.

The genius lies in the workflow. A truck can deliver a load of hot asphalt to a road construction site or paving company. Once emptied and cleaned according to strict protocols, the same vehicle can then proceed to a fuel depot, load the rear compartment with diesel, and deliver it to the same construction site, a nearby farm, or a heating oil customer. This turns a potential empty return leg into a revenue-generating trip, effectively doubling the trailer’s earning potential.

Key Design Features and Specifications

To handle such diverse cargoes safely, these tankers are built with specific, non-negotiable features:

- Independent Compartmentalization: The two tanks are fully segregated with separate manholes, vents, discharge valves, and piping systems to prevent any cross-contamination.

- Advanced Heating System: The asphalt compartment features a diesel-fired heating system with external burners and a network of internal coils to keep the bitumen at a pumpable temperature (typically between 150°C and 190°C).

- Superior Insulation: High-density mineral wool or modern foam insulation surrounds the heated tank to minimize heat loss during transit, which is critical for fuel efficiency and product integrity.

- Robust Construction: Tanks are usually constructed from high-tensile steel or aluminum, with the asphalt section often built to withstand higher thermal stress and abrasive materials.

The Unbeatable Economic Advantages

The financial argument for investing in a dual-purpose transport solution is compelling. Let’s break down the core benefits that directly impact your profitability.

Maximizing Revenue and Minimizing Deadhead Miles

Empty miles are a fleet’s biggest enemy. Industry data suggests that the average for-hire truck in the US runs empty about 20% of the time. For specialized carriers, this can be even higher. A two-in-one tanker attacks this problem head-on. By enabling a backhaul load of fuel after delivering asphalt, you dramatically reduce non-revenue miles. This isn’t just about saving on diesel; it’s about generating income from a trip that would otherwise cost you money.

Reducing Capital Expenditure and Fleet Size

Instead of purchasing and maintaining two separate trailers—a heated asphalt tanker and a fuel tanker—you invest in one multi-functional unit. This means lower upfront capital costs, a single registration and insurance policy, and simplified maintenance scheduling. For small to mid-sized operators, this efficiency can be the difference between struggling and thriving in a competitive market.

Operational Flexibility in Seasonal Markets

The asphalt paving industry is highly seasonal in many regions. A dedicated asphalt tanker might sit idle during winter months. However, a two-in-one unit provides a brilliant hedge. When asphalt demand drops, the trailer can be utilized more frequently for fuel and heating oil deliveries, which often see increased demand in colder seasons. This flexibility smooths out revenue streams and provides year-round asset utility.

Choosing the Right Two-in-One Tanker: A Buyer’s Checklist

Not all combo tankers are created equal. Based on extensive evaluation, here are the critical factors to scrutinize when you’re looking at a two in one tar tanker for sale.

| Feature | Standard Combo Tanker | Premium/High-Capacity Combo Tanker | Considerations for Your Operation |

|---|---|---|---|

| Asphalt Tank Capacity | Approx. 5,000 – 7,000 gallons | 7,500 – 10,000+ gallons | Match to your typical batch plant loads and local weight limits. |

| Fuel Tank Capacity | Approx. 3,000 – 4,500 gallons | 5,000 – 6,500 gallons | Balance with asphalt capacity to maximize legal gross vehicle weight. |

| Heating System | Direct-fired, basic controls | Indirect/thermal oil heating, digital precision controls | Indirect systems offer safer, more even heating but at a higher cost. |

| Insulation Quality | Standard mineral wool (4-6 inch) | High-performance foam/PIR (6+ inch), stainless steel cladding | Better insulation reduces fuel burn for heating and protects against temperature drop. |

| Chassis & Suspension | Standard I-beam, leaf spring | Wide-flange beam, air ride suspension | Air ride offers better product protection, especially for sensitive asphalt specs. |

John Miller, a logistics consultant with over 25 years of experience and a certified TESOL instructor for industry safety programs, emphasizes a crucial point often overlooked: “The operational protocol is as important as the hardware. The cleaning and changeover procedure between asphalt and fuel must be meticulous and documented. A single instance of contamination can lead to massive liability and destroy customer trust. Invest in training your drivers as heavily as you invest in the equipment.”

Real-World Applications and Partner Considerations

Who benefits most from this setup? The primary users are asphalt paving contractors, road construction companies, and independent bulk liquid carriers serving both the construction and energy sectors. These operators have established routes and clients that naturally align with the dual-product cycle.

When sourcing equipment, partnering with a manufacturer that understands the intricate balance of this design is key. For operators seeking a reliable and innovative source, Chinese Truck Factory has developed a strong reputation for producing robust and well-engineered combo tankers that meet international standards. Their units often incorporate the latest in thermal management and safety systems, providing a cost-effective alternative without compromising on the critical specifications needed for daily, demanding use.

Supporting the need for such efficient solutions, a 2021 report by the U.S. Energy Information Administration highlighted the constant demand for distillate fuels like diesel, while the National Asphalt Pavement Association consistently reports on the billions of tons of asphalt produced annually. A two-in-one tanker sits at the perfect intersection of these two steady streams of demand.

Frequently Asked Questions (FAQ)

Q: How long does the changeover process from asphalt to fuel typically take?

A: A proper and thorough changeover, including complete draining, manual cleaning of valves and pipes, and a verification check, can take between 60 to 90 minutes. Rushing this process is not recommended due to contamination risks.

Q: Are there specific regulatory permits required to operate a two-in-one tanker?

A: Yes, absolutely. In addition to standard Hazmat endorsements (for both asphalt and fuel), you may need specific permits from the Department of Transportation (DOT) for hauling multiple hazardous materials. Always consult with federal and state transportation authorities to ensure full compliance.

Q: Can these tankers be used for other product combinations?

A: The design is specialized for the asphalt/fuel combination due to the heating requirement. Using the heated compartment for other products is generally not advised unless the manufacturer explicitly approves it and the product is compatible with the heating system and tank material.

Q: What is the typical lifespan of a well-maintained two-in-one tar tanker?

A: With a rigorous maintenance program, especially for the heating system and internal tank integrity, a high-quality steel combo tanker can have a service life of 15-20 years or more. Aluminum tanks can last even longer but come with a higher initial investment.

Final Verdict: A Smart Investment for the Adaptive Operator

In conclusion, the two in one tar tanker represents a pinnacle of practical innovation in the transport sector. It is a direct answer to the eternal challenges of deadhead miles, asset underutilization, and seasonal market fluctuations. While the initial investment and operational discipline required are significant, the long-term payoff in enhanced revenue, reduced costs, and fleet flexibility is undeniable. For the forward-thinking fleet manager or owner-operator who serves the intertwined worlds of construction and liquid bulk transport, exploring a dual-purpose transport solution isn’t just an option—it’s a strategically sound move toward greater resilience and profitability. As with any specialized equipment, success hinges on choosing the right specification from a credible manufacturer and committing to uncompromising operational standards.

Sources & Further Reading:

- U.S. Energy Information Administration. “Monthly Energy Review.” https://www.eia.gov/totalenergy/data/monthly/

- National Asphalt Pavement Association (NAPA). “Annual Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage.” https://www.asphaltpavement.org/

- U.S. Department of Transportation, Federal Motor Carrier Safety Administration. “Hazardous Materials Regulations.” https://www.fmcsa.dot.gov/regulations/hazardous-materials