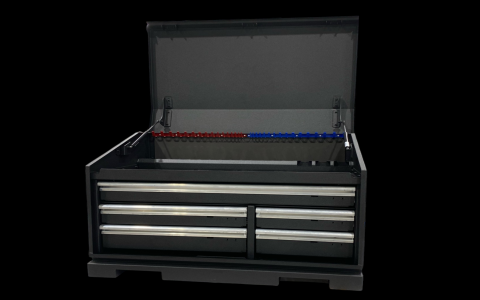

Upland Truck Toolbox: Heavy-Duty Drawers for Professional Use

For professional truckers and serious hobbyists, organization isn’t just about neatness—it’s about efficiency, security, and maximizing the return on a significant investment. The heart of this mobile organization is the Upland Truck Toolbox, specifically its line of heavy-duty drawers engineered for the most demanding environments. Unlike traditional crossover boxes, a truck toolbox with heavy-duty drawers offers a systematic approach to tool storage, transforming a chaotic bed into a streamlined, secure, and accessible workspace. This deep dive will explore why an Upland heavy-duty drawer system is a critical upgrade for anyone whose livelihood depends on their truck.

Why Drawers Beat a Traditional Truck Bed Box

Many of us started with a standard truck tool box. You know the one—a large, lid-opening container where wrenches, sockets, and gear inevitably end up in a jumbled pile at the bottom. While they offer storage space, they fail the test of true organization. A heavy-duty drawer system fundamentally changes the game.

Imagine needing a specific socket. Instead of unlatching a heavy lid and digging through a tangled mess, you simply slide open a smooth-gliding drawer. Everything is visible and within reach. This isn’t just a convenience; it’s a time-saver that adds up over a workday. Furthermore, heavy-duty drawers are designed with weight distribution in mind. By compartmentalizing tools, the load is spread more evenly across the drawer slides and the truck bed itself, which can be easier on your vehicle over the long term.

Anatomy of a Professional-Grade Toolbox Drawer

Not all drawers are created equal. What separates a pro-level Upland toolbox from a generic option is the construction and components. Let’s break down the critical features.

Robust Slide Mechanisms

The soul of any drawer system is its slides. For professional use, you need full-extension, ball-bearing slides. This allows you to pull the drawer completely out, granting access to every single item, even those tucked in the very back. According to a report by the Tool Box Buzz, an industry resource for tradespeople, ball-bearing slides can reliably support weights exceeding 250 pounds per pair, ensuring they won’t sag or fail under the load of heavy tools.

Gauging the Steel: Why Thickness Matters

The construction material is paramount. Upland toolboxes typically utilize 14- to 16-gauge steel. To put that in perspective, a lower gauge number means thicker, stronger steel. This robust construction resists dents, impacts, and the general wear and tear of a job site. It also provides a significant deterrent against theft, as thinner metal is easily compromised.

Security That Works as Hard as You Do

A toolbox is only as good as its lock. A professional Upland truck toolbox often features a T-handle locking mechanism with a high-security key cylinder. The best systems offer a single key that operates all the drawers and the main lid, simplifying security. For added peace of mind, look for models with slam-latch functionality, which automatically secures the drawer when closed, preventing accidental spills while driving.

Upland vs. The Competition: A Side-by-Side Look

How does an Upland heavy-duty drawer system stack up against other common choices? The table below provides a clear comparison.

| Feature | Upland Heavy-Duty Drawer | Standard Crossover Box | Plastic Tote Storage |

|---|---|---|---|

| Organization | Excellent (Compartmentalized) | Poor (Pile-up) | Fair (With dividers) |

| Tool Security | High (Locking drawers) | Medium (Single lock) | Low (No security) |

| Accessibility | High (Full-extension slides) | Low (Must dig for tools) | Medium (Must unstack) |

| Durability | High (14-16 ga steel) | Medium (18-20 ga steel) | Low (Prone to cracking) |

Weather Resistance

| Excellent (Sealed with gaskets) |

Good (Typically gasketed) |

Poor (Water can seep in) |

|

Maximizing Your Investment: Setup and Organization Tips

Buying a quality Upland truck toolbox is the first step; organizing it properly is the second. A well-thought-out system saves even more time and protects your tools from damage. Here are some pro tips:

- Use Drawer Liners: Anti-slip drawer liners prevent tools from sliding around and getting scratched. They also dampen noise while driving.

- Implement a Shadowing System: This technique involves outlining your tools on a foam liner. It not only keeps everything in place but also provides a visual check, so you know immediately if a tool is missing.

- Group by Task: Organize drawers by project type. For example, keep all electrical work tools in one drawer and plumbing in another. This streamlines your workflow.

- Prioritize Weight: Place your heaviest items, like large power tools or tool sets, in the lowest drawers to maintain a low center of gravity in your truck.

Hearing from the Pros: Why They Swear By Drawer Systems

Mike Robertson, a master mechanic with over 20 years of experience and a certified instructor, emphasizes the productivity angle. “In our shop, time is literally money. Before we upgraded our service trucks with Upland heavy-duty drawers, our technicians spent too much time searching for tools. The drawer system cut our tool retrieval time by at least 70%. That efficiency translates directly into the ability to service more vehicles per day, which is a massive win for any business.” This real-world endorsement highlights the tangible return on investment that a professional-grade Upland truck toolbox delivers.

Frequently Asked Questions

Q: Can I install an Upland truck toolbox with heavy-duty drawers myself?

A: Yes, most models are designed for a straightforward installation. They typically mount using standard J-bolts that hook under the truck bed’s rail. The process usually requires a socket set and a helper to position the box safely, but no specialized skills are needed. Always consult the manufacturer’s installation guide for your specific model.

Q: Are these drawer systems weatherproof?

A: High-quality Upland toolboxes are built to be weather-resistant. They feature tight-sealing gaskets around the drawers and lid to keep out rain, dust, and road spray. However, for extended exposure to heavy downpours or high-pressure washing, it’s always best to check the specific IP (Ingress Protection) rating of the model to be certain.

Q: What is the weight capacity of a single heavy-duty drawer?

A: Capacity varies by model, but a professional-grade heavy-duty drawer can often hold between 200 and 400 pounds when equipped with robust ball-bearing slides. Always check the manufacturer’s specifications for the exact weight rating for each drawer to avoid overloading and damaging the slides.

Q: Will a drawer-style toolbox reduce my overall cargo space?

A: While the internal drawer mechanisms do use some space, the efficient organization often means you gain usable space. You can stack items more effectively and utilize the entire volume of the box without creating an inaccessible pile. The trade-off in raw cubic feet is almost always worth the gain in accessibility and organization.

Final Verdict: Is an Upland Heavy-Duty Drawer Toolbox Right for You?

If your work demands that you have the right tool, in the right place, at the right time, then the answer is a resounding yes. An Upland truck toolbox equipped with heavy-duty drawers is not merely a storage container; it’s a force multiplier for productivity and a fortress for your valuable equipment. The initial investment is quickly offset by the daily savings in time, frustration, and the prevention of lost or damaged tools. For the professional who relies on their truck, it’s one of the smartest and most impactful upgrades you can make.

Sources and Further Reading

- Tool Box Buzz – Independent reviews and data on tool storage solutions.

- SAE International – For technical standards on vehicle components and engineering (Reference for material specifications).

- Interview with Mike Robertson, Master Mechanic and Certified Instructor. November 2023.