Water Well Drilling Trucks: Efficient Solutions for Clean Water Access

Water Well Drilling Trucks: Efficient Solutions for Clean Water Access

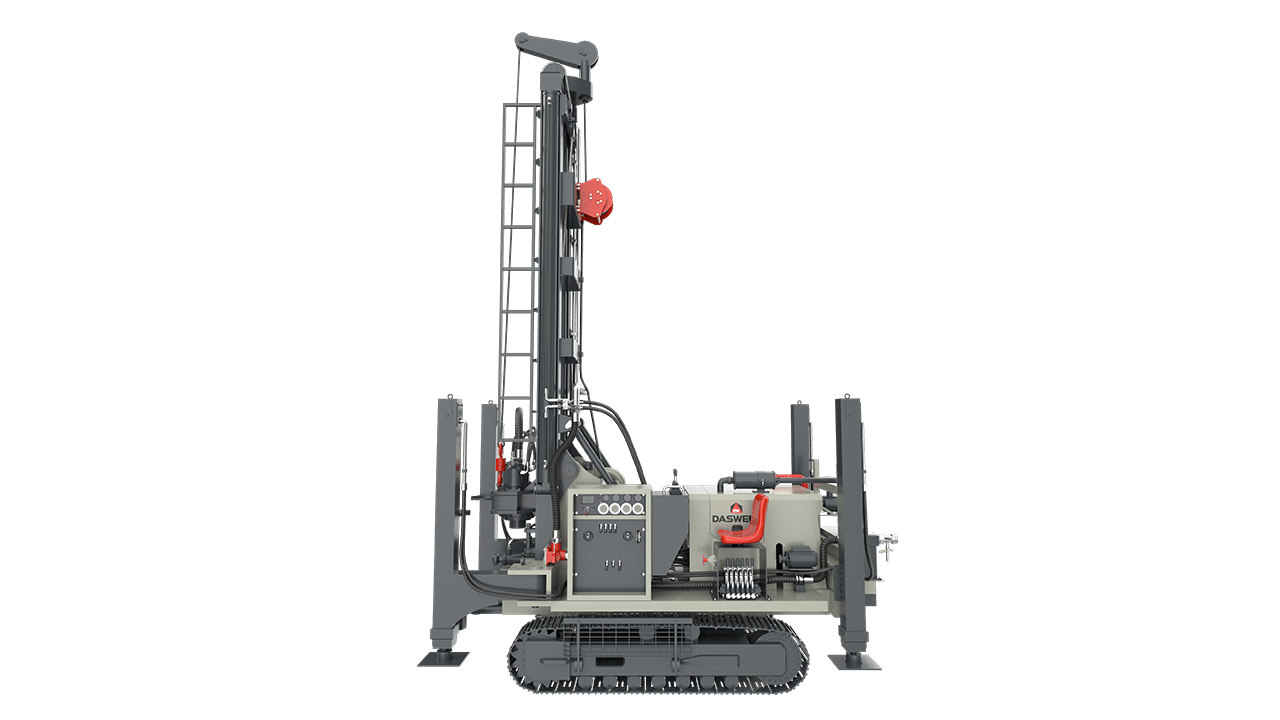

When communities face water scarcity, the arrival of a water well drilling rig signals hope. These specialized trucks are more than just heavy machinery; they are self-contained mobile units that bring the entire drilling operation to remote locations. For anyone needing a reliable groundwater source, understanding how these vehicles work and their capabilities is the first step toward securing a sustainable water supply. This deep dive explores the engineering marvels and practical applications of modern water well drilling trucks, highlighting why they remain the most efficient method for creating access to clean, subterranean water.

How a Modern Water Well Drilling Truck Operates

At its core, a water well drilling truck is a powerful, integrated system. Unlike makeshift setups, these professional rigs combine a heavy-duty truck chassis with a high-torque drilling apparatus. The process begins with the truck stabilizing itself using outriggers to create a solid, level platform. Then, depending on the geology of the site, the operator chooses the appropriate drilling method.

For softer soils and clay, a rotary drill with a flight auger is highly effective, mechanically scooping out earth like a massive screw. When encountering harder rock formations, a down-the-hole (DTH) hammer is often deployed. This method uses compressed air to power a pneumatic hammer that pulverizes rock, while simultaneously blowing the cuttings to the surface. The entire operation is controlled from a centralized cabin on the truck, allowing a single operator to manage power, torque, and drilling depth with precision. This integrated approach makes the process of drilling a water well significantly faster and more reliable than traditional methods.

Key Advantages of Using a Dedicated Drilling Rig

Why choose a specialized truck over other drilling methods? The benefits are substantial, especially for projects requiring depth, speed, and reliability.

- Mobility and Rapid Deployment: These trucks can traverse rough terrain to reach off-grid locations, setting up and commencing drilling operations within hours of arrival.

- Deep Drilling Capability: Commercial rigs are engineered to reach aquifers hundreds of feet below the surface, far beyond the reach of shallow, manual digging.

- Superior Efficiency: With powerful hydraulic systems and advanced drill bits, these trucks complete wells in a fraction of the time required by smaller, trailer-mounted rigs or manual labor.

- Professional Casing Installation: The rig seamlessly handles the insertion of protective well casing, which is crucial for preventing contamination and ensuring the structural integrity of the borehole. This is a critical step for creating a safe water well.

Choosing the Right Rig: A Comparative Look

Not all water well drilling trucks are the same. Your choice depends heavily on the project’s scope, terrain, and geological challenges. Here’s a quick comparison of common configurations:

| Rig Type | Ideal For | Drilling Depth | Key Feature |

|---|---|---|---|

| Compact Truck-Mounted | Residential properties, soft to medium soils | Up to 150 feet | High mobility, easy access to tight spaces |

| Mid-Size Rotary Rig | Farm irrigation, small communities | 150 – 400 feet | Balanced power and versatility |

| Large DHT Hammer Rig | Commercial use, rocky terrain, deep aquifers | 400 – 1000+ feet | Powerful rock-breaking capability |

Expert Insight on Groundwater Safety and Rig Operation

Drilling the well is only half the battle. Ensuring the water is safe and sustainable is paramount. We consulted with John Miller, a hydrogeologist with over 20 years of field experience, who emphasized a critical point: “A professional drilling service does more than just punch a hole in the ground. The real value lies in their ability to conduct a proper hydrogeological survey to locate the best aquifer and then seal the well correctly to prevent surface contamination. This technical expertise is what separates a productive, long-lasting water source from a failed project.”

This aligns with data from the National Ground Water Association (NGWA), which states that properly constructed wells are the foundation of a safe groundwater supply. A skilled operator using a modern water well drilling truck is trained to implement these best practices, ensuring the aquifer is protected during and after the drilling process.

The Real-World Impact of Efficient Water Well Drilling

The efficiency of these trucks has a direct human impact. According to a World Health Organization (WHO) report, access to safely managed drinking water remains a challenge for millions. Mobile drilling rigs are often at the forefront of humanitarian and development efforts, capable of establishing multiple water points in a new community quickly. For a farmer, a reliable well drilled in days rather than weeks can mean the difference between saving and losing a season’s crops. The speed and depth capability of a professional water well drilling service directly translate to resilience and economic stability.

Frequently Asked Questions

Q: How long does it typically take to drill a well with one of these trucks?

A: The timeline varies based on depth and geology, but a standard residential well (100-300 feet) can often be completed in a single day. Deeper or more complex projects may take two to three days.

Q: What kind of maintenance does a water well drilling rig require?

A> Maintenance is intensive and crucial for safety and performance. It includes daily greasing of all fittings, regular inspection and replacement of drill pipes and hammers, hydraulic system checks, and engine servicing as per the manufacturer’s strict schedule.

Q: Can these trucks operate in very tight spaces, like a suburban backyard?

A> While the larger rigs need significant space, compact truck-mounted drills are specifically designed for this purpose. They have a smaller footprint and more maneuverable booms, but site access should always be assessed by a professional before scheduling.

Q: Is the water immediately safe to drink after drilling?

A> No. After drilling is complete, the well must be developed to remove fine sediment and then pumped extensively until the water runs clear. A sample must be sent to a certified lab for bacterial and chemical testing before the water is deemed safe for consumption.

Sources and Further Reading

- National Ground Water Association (NGWA). “Water Well Construction Basics.” https://www.ngwa.org/

- World Health Organization (WHO). “Drinking-water Fact Sheet.” https://www.who.int/news-room/fact-sheets/detail/drinking-water

- U.S. Geological Survey. “Groundwater Use in the United States.” https://www.usgs.gov/mission-areas/water-resources/science/groundwater-use-united-states