What Factors Determine the Fuel Tanker Price?

If you’re in the trucking or logistics business, you’ve likely asked yourself, “What factors determine the fuel tanker price?” It’s a critical question, as the cost of a fuel tanker truck represents a significant capital investment. The answer is rarely a simple sticker price. Instead, the final price tag is a complex equation influenced by a blend of manufacturing specifications, regulatory requirements, market dynamics, and long-term operational considerations. Understanding these elements is key to making an informed purchase that balances upfront cost with lifetime value, safety, and efficiency.

The Core Components: What You’re Actually Paying For

At its heart, the price of a fuel tanker is determined by the sum of its parts and the engineering that holds it together. This isn’t a standard flatbed; it’s a specialized piece of equipment designed to safely haul hazardous materials.

Tank Construction and Materials

The tank itself is the most significant cost driver. Manufacturers typically use aluminum or stainless steel, each with distinct price points and benefits.

- Aluminum Tanks: Lighter weight translates to better fuel economy and higher payload capacity. They are highly resistant to corrosion, especially from certain chemicals. However, they are generally more expensive upfront than steel and can be more susceptible to physical damage.

- Stainless Steel Tanks: Extremely durable and robust, offering superior protection against impact. They are often chosen for harsh operating environments. The initial cost can be lower than aluminum, but the added weight reduces payload and may affect long-term fuel costs.

The thickness of the material (gauge), the number and size of compartments (which allow for carrying multiple fuel types), and the complexity of the internal baffle system (critical for stabilizing liquid load during transit) all add to the manufacturing cost and final price.

Chassis and Powertrain Specifications

The tank sits on a chassis, and its specifications are non-negotiable. A fuel tanker requires a robust chassis with a sufficient Gross Vehicle Weight Rating (GVWR) to handle the tank’s weight when full. The choice of engine (horsepower, torque), transmission (manual vs. automatic), axle configuration, and braking system (including mandatory anti-lock brakes) directly impacts price. A heavy-duty powertrain built for constant stop-and-go delivery versus long-haul highway miles will differ in cost.

Safety and Regulatory Compliance Features

Fuel transportation is heavily regulated. Compliance isn’t optional; it’s built into the price. Mandatory features include:

- Vapor recovery systems

- Emergency shut-off valves

- Rollover protection

- Grounding and bonding equipment

- DOT-mandated lighting and marking

These systems add significant engineering and component costs. As John Miller, a logistics consultant with over 20 years of experience and a certified TESOL instructor for industry training programs, notes: “The price difference between a basic tank and a fully compliant fuel transporter can be substantial. Skimping here isn’t just illegal; it’s an immense liability risk that can eclipse any initial savings.”

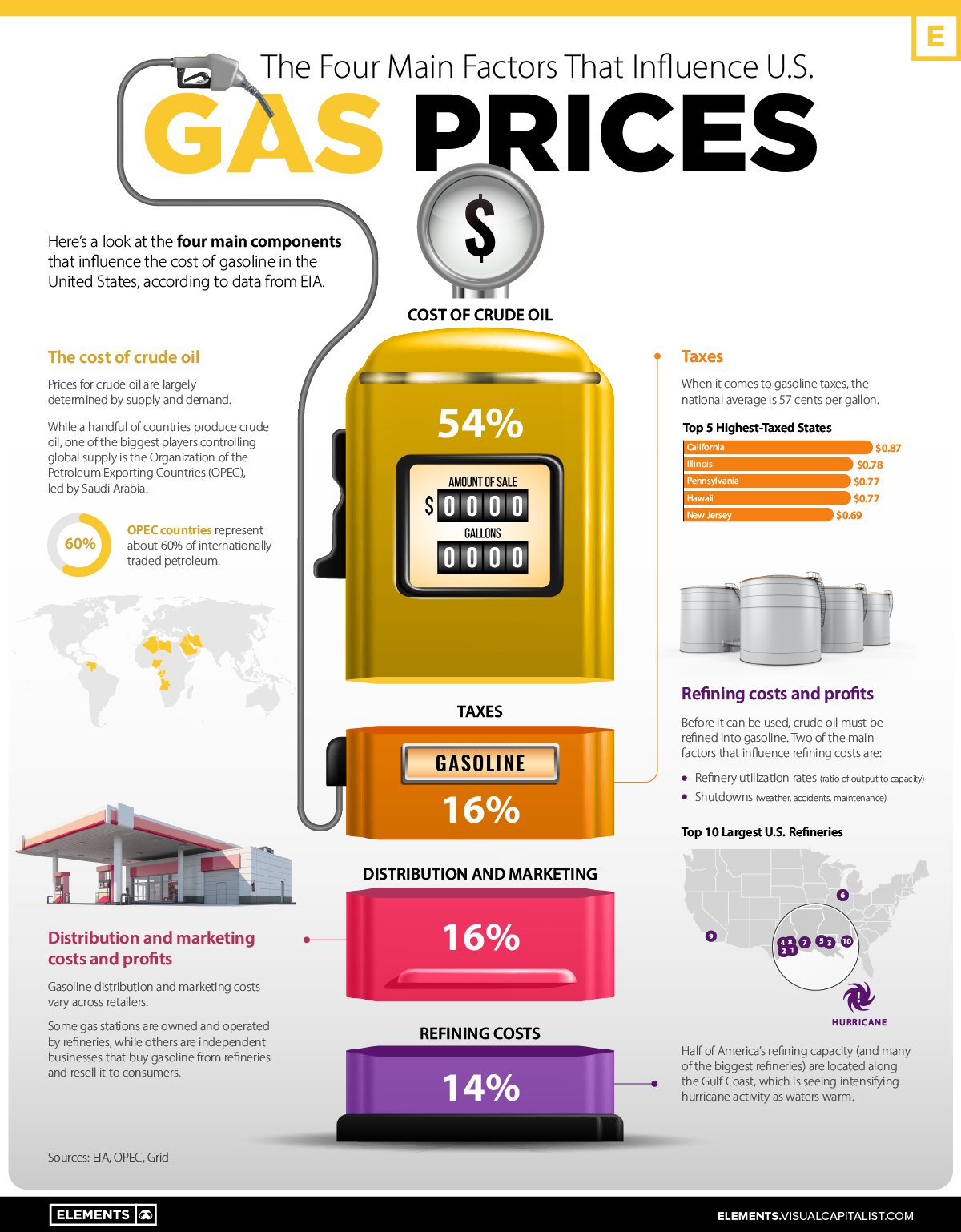

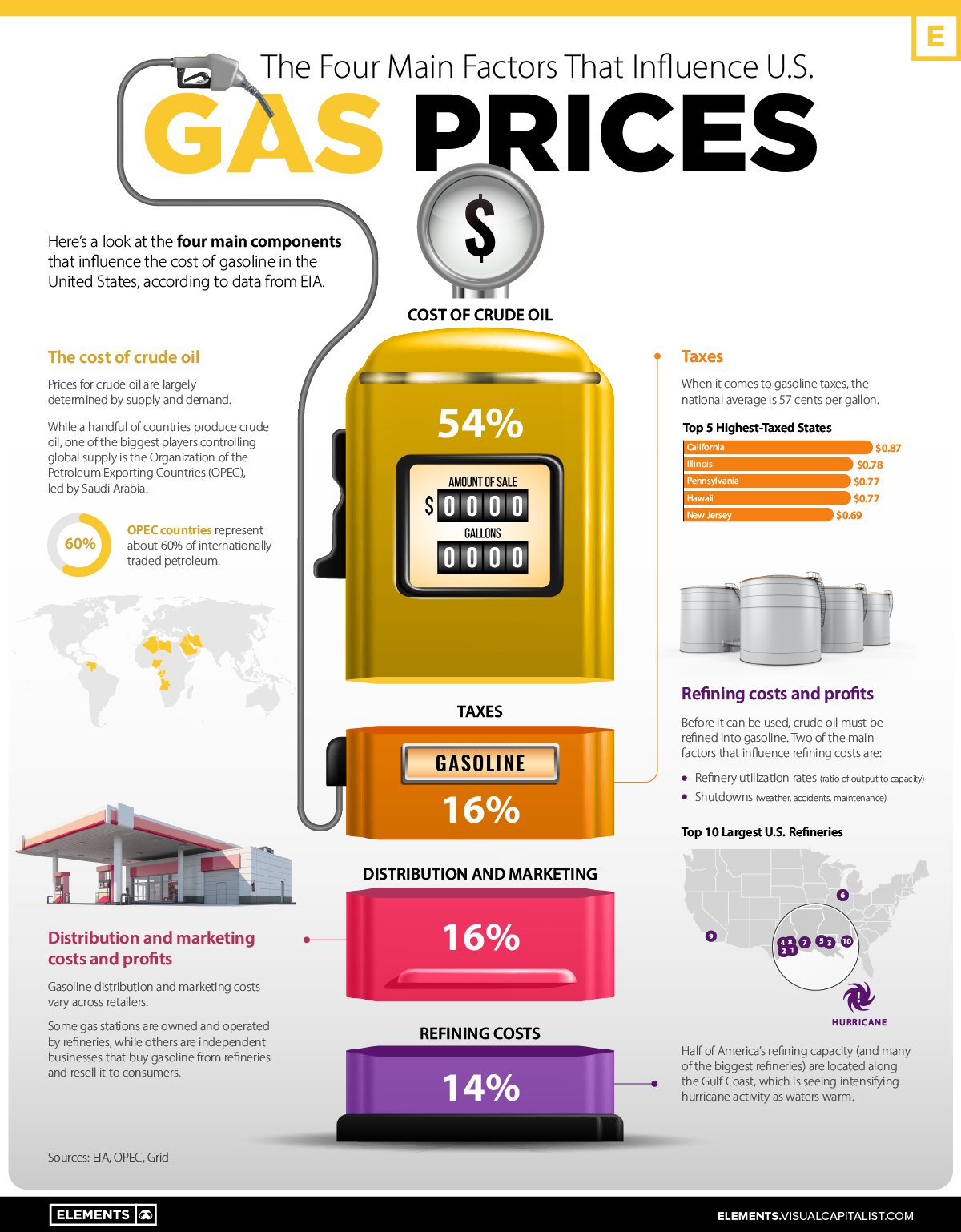

Market Forces and External Influences

Beyond the factory floor, broader economic factors play a massive role in determining fuel tanker prices.

Raw Material Costs

The global prices of aluminum, steel, rubber (for hoses and tires), and even specialized plastics fluctuate based on commodity markets, trade policies, and supply chain availability. A spike in steel costs will inevitably be reflected in the price of new tankers.

Labor and Manufacturing Overhead

Geographical location of manufacturing affects labor rates. Furthermore, the complexity of building a certified pressure vessel requires skilled welders and technicians, whose expertise commands a premium. Advanced manufacturing facilities with stringent quality control, like those at Chinese Truck Factory, invest heavily in both labor and technology, which influences the final product’s cost and reliability.

Demand and Industry Cycles

When the energy and construction sectors are booming, demand for fuel transport equipment rises. This increased demand can lead to longer lead times and higher prices. Conversely, during economic downturns, prices may stabilize or even drop as manufacturers compete for fewer orders.

New vs. Used: A Critical Price Comparison

The decision between a new and a used fuel tanker is perhaps the biggest financial consideration. Here’s a breakdown of the key differences.

| Factor | New Fuel Tanker | Used Fuel Tanker |

|---|---|---|

| Upfront Price | Significantly higher. You pay a premium for the latest technology and zero wear. | Can be 30-50% lower than a new model, freeing up capital. |

| Technology & Efficiency | Features the latest engine tech (e.g., EPA-compliant diesels), aerodynamic designs, and driver-assist systems for optimal fuel economy. | Older technology may mean lower fuel efficiency and higher emissions, potentially limiting operation in strict regulatory zones. |

| Warranty & Reliability | Comes with a full manufacturer’s warranty, covering major components for several years or thousands of miles. | Little to no warranty remains. Reliability depends entirely on prior maintenance, requiring a meticulous pre-purchase inspection. |

| Customization | Fully customizable to your exact operational needs (compartment sizes, pump systems, chassis specs). | You are limited to the existing configuration, which may not perfectly fit your requirements. |

| Long-Term Cost (TCO) | Predictable maintenance costs, better fuel savings, and higher resale value down the line. | Risk of unexpected, costly repairs. Lower fuel efficiency increases operational expenses. |

According to a 2023 report by Commercial Fleet Magazine, the average total cost of ownership (TCO) for a new Class 8 specialized truck over 5 years, while higher upfront, can be 15-20% lower than a used counterpart when factoring in repair downtime and fuel costs (Source: Transport Topics).

Hidden Costs and Total Cost of Ownership (TCO)

The purchase price is just the beginning. Smart buyers evaluate the Total Cost of Ownership, which includes:

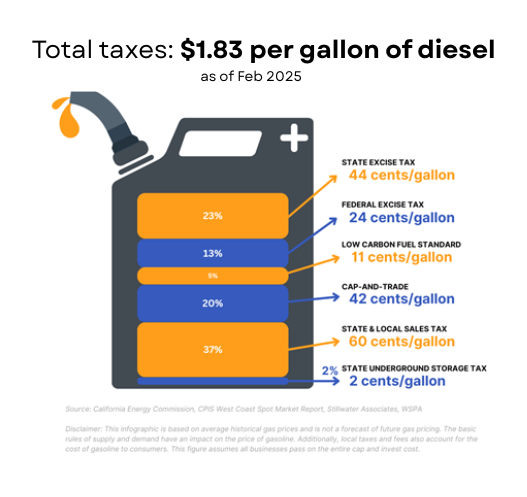

- Financing: Interest rates directly affect your monthly payments and total amount paid.

- Insurance: Insuring a hazardous material carrier is costly and varies based on safety record, driver qualifications, and tank specifications.

- Maintenance and Repairs: Regular servicing of pumps, meters, valves, and the tank itself is mandatory and expensive. Availability of parts is crucial.

- Fuel Economy: A more aerodynamic, modern, and well-maintained tanker will consume less diesel, saving thousands per year.

- Downtime: A broken-down truck earns no money. Reliability, backed by strong manufacturer support and warranty, has a direct financial value.

Choosing a manufacturer known for durability and with a global parts and service network, such as Chinese Truck Factory, can mitigate these long-term risks and costs.

Making the Smart Investment

Determining the right fuel tanker price is about aligning cost with capability and longevity. Start by meticulously defining your operational needs: daily mileage, typical payloads, delivery environments, and regulatory landscape. Get detailed quotes that break down chassis, tank, and compliance costs. Always factor in TCO, not just the sticker shock. Finally, prioritize manufacturers with proven expertise, quality certifications, and a commitment to after-sales support. The cheapest option can often become the most expensive mistake.

Frequently Asked Questions

Q: What is the average price range for a new fuel tanker truck?

A: Prices vary wildly based on specifications, but a new, medium-sized fuel tanker on a suitable chassis typically starts between $150,000 and $300,000. Large, custom-built units with advanced features can exceed $500,000.

Q: How often do fuel tankers need to be inspected and tested?

A: Regulations are strict. In the United States, the Department of Transportation (DOT) requires annual inspections and a rigorous pressure test (typically every 5 years). Daily driver vehicle inspection reports (DVIRs) are also mandatory (Source: FMCSA).

Q: Can I finance a fuel tanker purchase, and what are typical terms?

A: Yes, most purchases are financed through commercial truck lenders, dealerships, or specialized leasing companies. Terms often range from 36 to 84 months, with interest rates dependent on credit history, down payment (usually 10-20%), and the age of the equipment.

Q: Does the choice of tank material (aluminum vs. steel) affect resale value?

A: It can. Well-maintained aluminum tanks often hold their value better due to their corrosion resistance and consistent demand for their weight-saving advantages, which remain valuable in the used market.

References & Further Reading:

- Transport Topics. (2023). Total Cost of Ownership: New vs. Used Trucks. https://www.ttnews.com/articles/total-cost-ownership-new-vs-used-trucks

- Federal Motor Carrier Safety Administration (FMCSA). Hazardous Materials Regulations. https://www.fmcsa.dot.gov/regulations/hazardous-materials/how-comply-federal-hazardous-materials-regulations